End shaft drilling device

A technology of drilling device and end shaft, which is applied in the direction of feeding device, boring/drilling, drilling/drilling equipment, etc. It can solve the problems of potential safety hazards in mobile drills and difficult removal of iron filings, etc., to improve safety , Operational safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

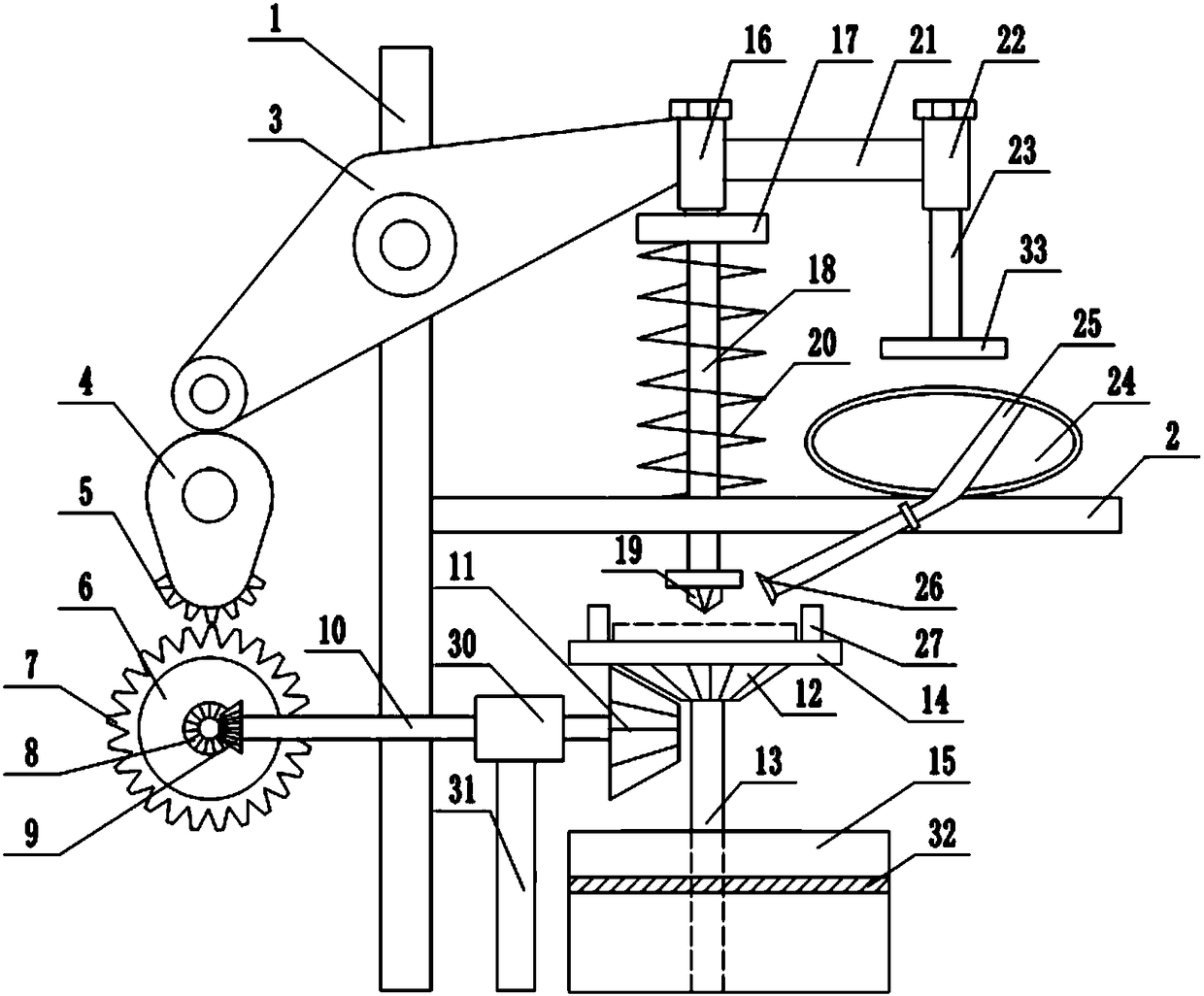

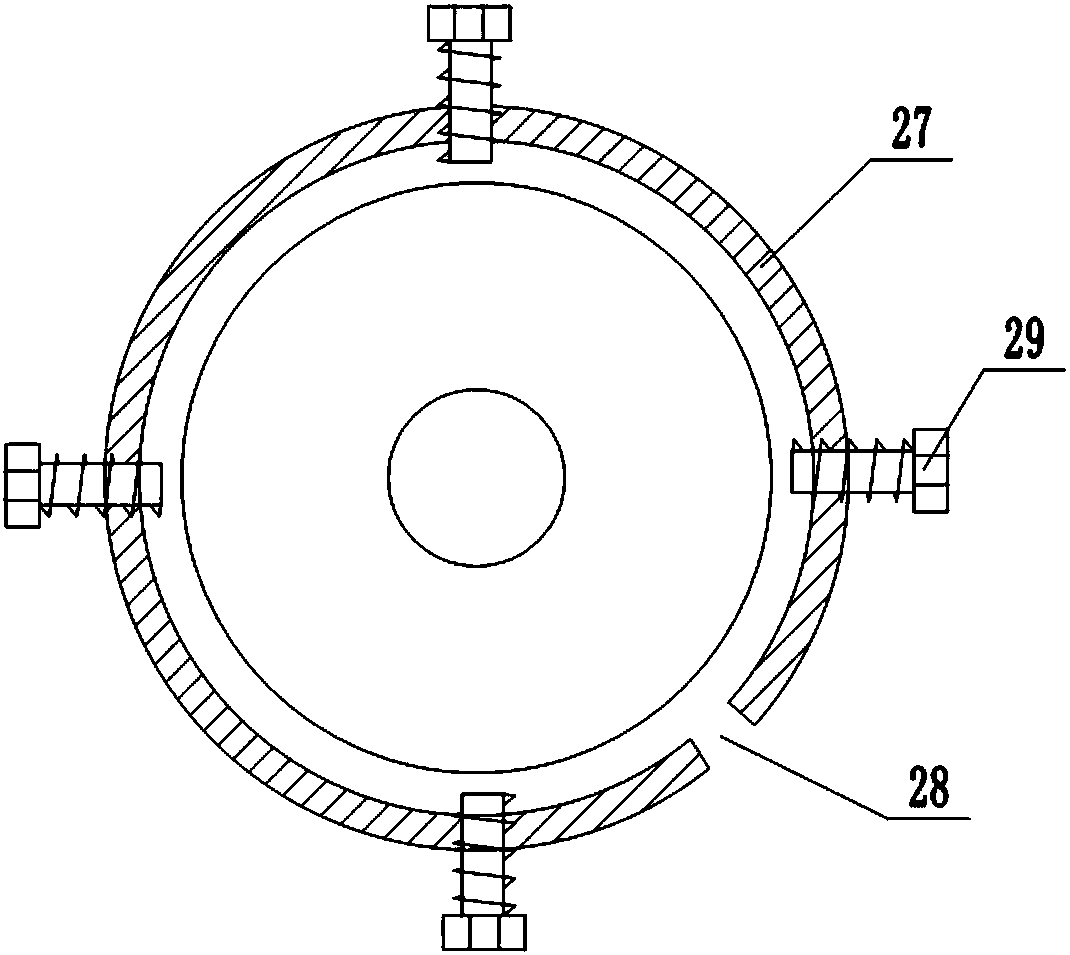

[0018] The reference signs in the accompanying drawings of the description include: frame 1, support platform 2, triangular plate 3, cam 4, first tooth 5, turntable 6, second tooth 7, first bevel gear 8, second bevel gear 9, horizontal Shaft 10, third bevel gear 11, fourth bevel gear 12, support shaft 13, support plate 14, collection box 15, first fixed block 16, first support plate 17, slide bar 18, drill bit 19, support spring 20, Horizontal plate 21, second fixing block 22, push rod 23, water bag 24, water spray pipe 25, nozzle 26, positioning frame 27, water outlet 28, bolt 29, collar 30, support rod 31, filter screen 32, pressure plate 33.

[0019] The embodiment is basically as figure 1 , figure 2 Shown: a terminal shaft drilling device, including a frame 1 and a support platform 2 fixed on the frame 1, a triangular plate 3 is rotatably connected to the frame 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com