Damping type building rubbish crushing treatment device

A processing device and construction waste technology, applied in grain processing, non-rotational vibration suppression, etc., can solve the problems of reducing the overall quality of waste crushing, reducing the service life of the crushing device, and the garbage cannot be completely crushed, so as to reduce the service life and reduce the Noise, the effect of ensuring thoroughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

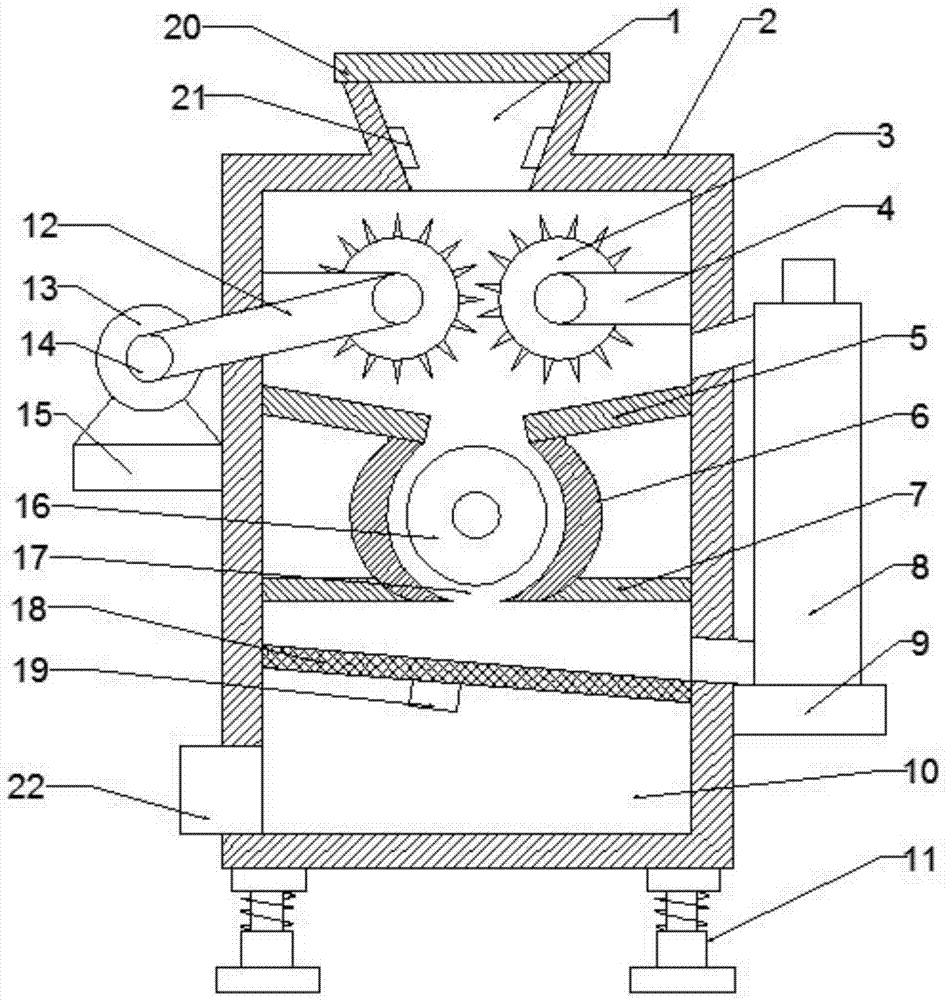

[0016] see figure 1 , this embodiment provides a shock-absorbing construction waste crushing device, including a box body 2, a support rod 4, a support plate 9, a storage bin 10, a shock-absorbing base 11, a motor base 15, a rolling bin 17 and a sieve Net 18; the top of the box body 2 is provided with a feed hopper 1, and the feed hopper 1 is conical; the top of the feed hopper 1 is hinged with a cover plate 20, and the inside is fixedly provided with a powerful magnet 21, and the powerful magnet 21 is The circular ring can absorb the magnetic metal in the construction waste in the feed hopper 1; the motor base 15 is fixedly arranged on the left side of the casing 2 by welding, and the motor base 15 is provided with a drive motor 13; The driving motor 13 is provided with a belt pulley 14, which is connected with the crushing roller 3 through the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com