Stirring device for ink and resin mixing

A stirring device, ink resin technology, applied in mixers, mixer accessories, mixers with rotating containers, etc., can solve the problem of not being able to mix quickly and evenly, and achieve the effect of speeding up the mixing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

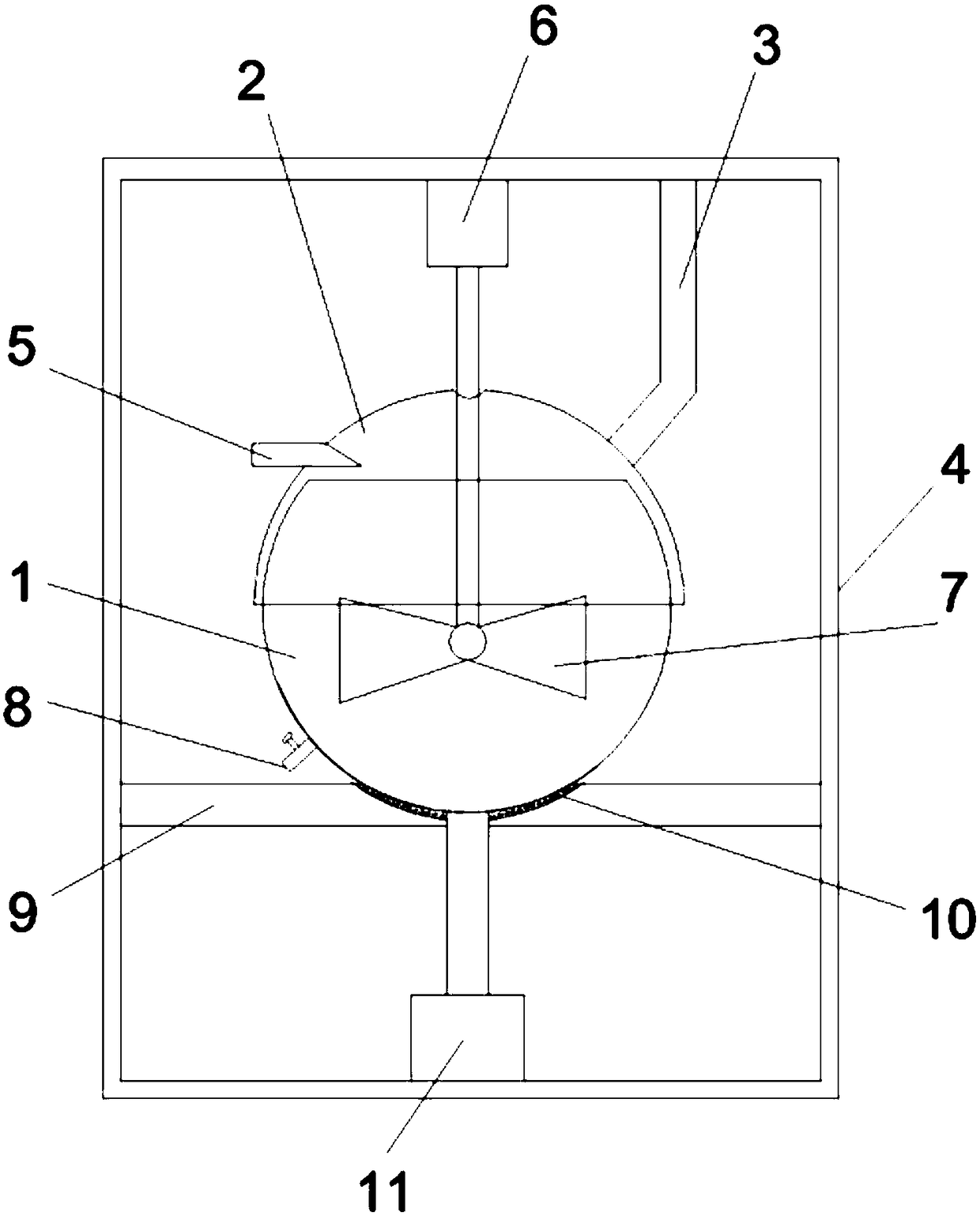

[0011] A stirring device for ink resin mixing, comprising a stirring tank body 1, a tank body upper cover 2, a cover connecting piece 3, an outer frame body 4, a feeding port 5, a stirring motor 6, a stirring rod 7, and a discharge valve 8. Kettle body fixed support plate 9, ball 10, kettle body driving motor 11; the lower part of the stirring kettle body 1 is spherical; the bottom of the stirring kettle body 1 is connected to the kettle body driving motor 11, and the kettle body driving motor 11 Drive stirring kettle body 1 to rotate; Described kettle body driving motor 11 is fixed on the bottom of external frame body 4; Described kettle body fixed supporting plate 9 two ends connect external frame body 4; Described kettle body fixed supporting plate 9 middle parts are provided with for Pass through the hole of the motor shaft of the kettle body driving motor 11; the upper surface of the middle part of the fixed supporting plate 9 of the kettle body is provided with a groove m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com