Agitator of polymerizer for producing PVC resin paste by emulsion polymerization

A technology of polyvinyl chloride paste and agitator, which is applied in the field of agitator of polyvinyl chloride paste resin polymerization kettle produced by emulsion polymerization, which can solve the problems of low production capacity and uneven temperature of the polymerization kettle, and achieve high heat transfer effect, Improve the effect of stirring, mixing and heat transfer, and increase production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

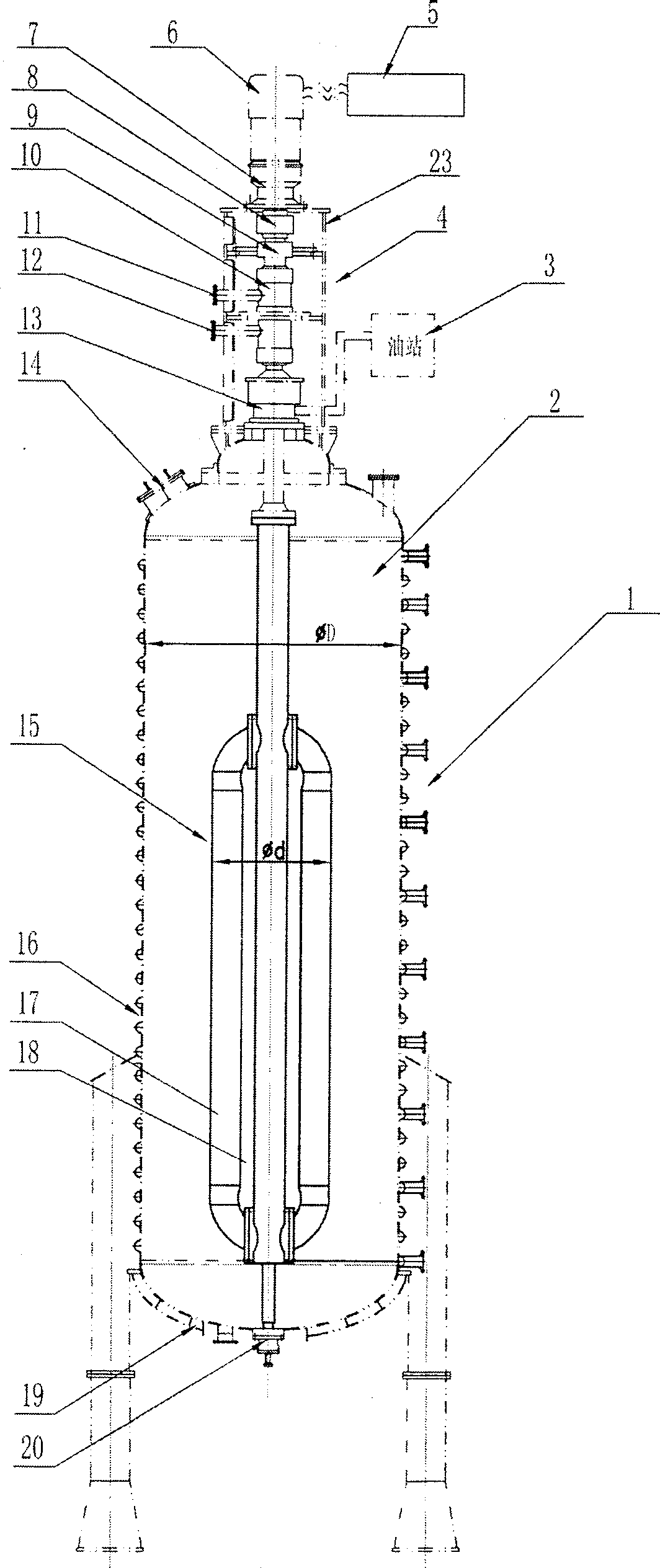

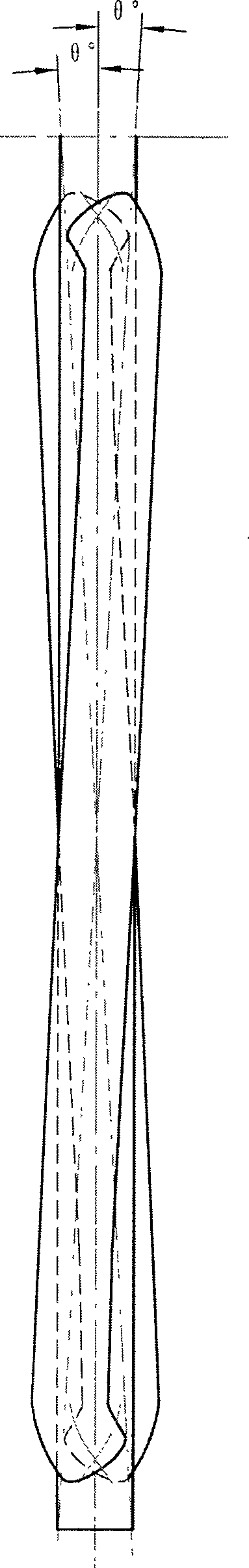

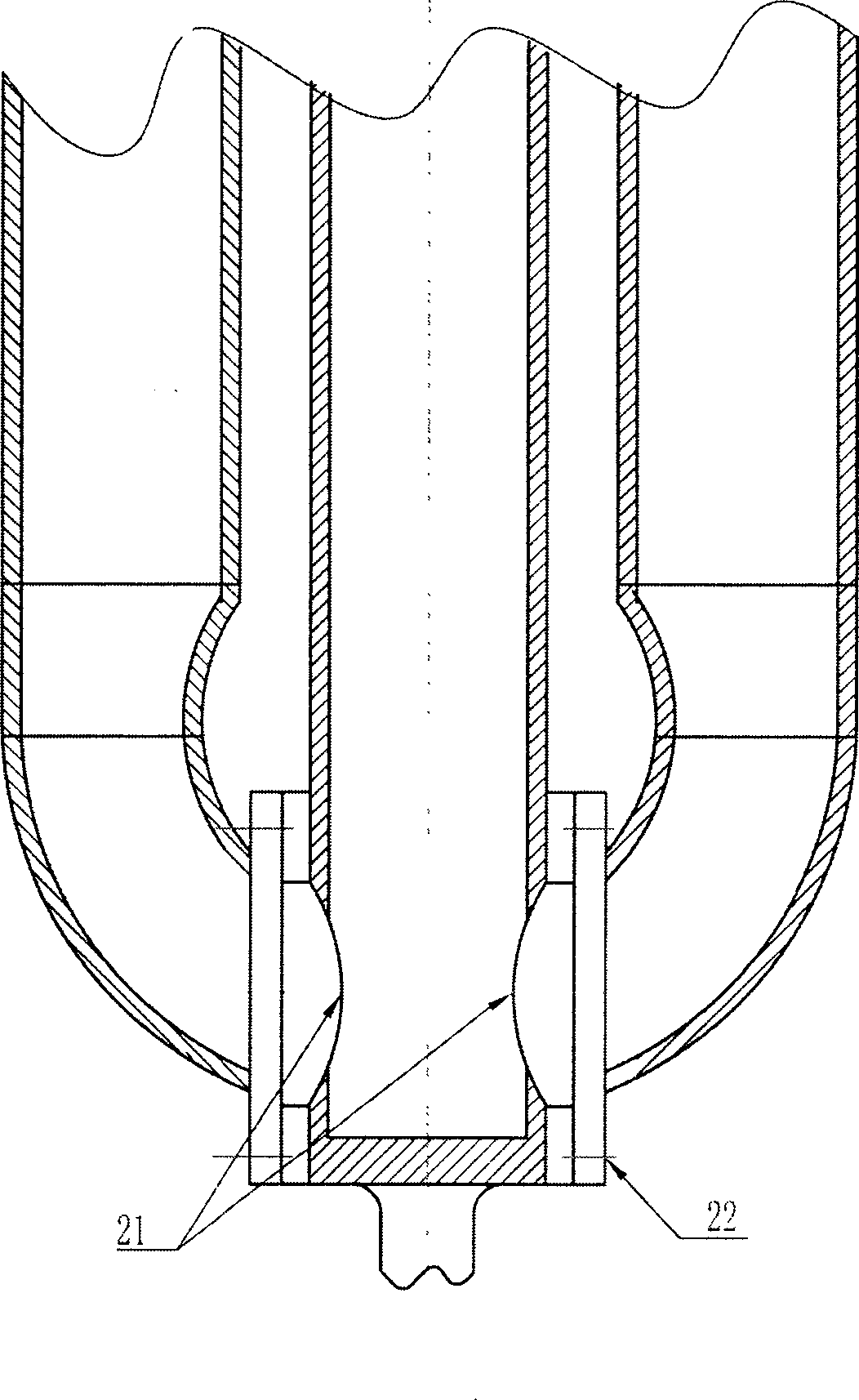

[0017] The agitator used for emulsion method polymerization to produce polyvinyl chloride paste resin polymerization kettle, agitator 15 includes agitator shaft 18, annular pipe type agitator paddle 17, agitator 15 is installed in polymerization kettle 1, agitator shaft 18 is hollow type, A ring-type stirring paddle 17 is installed on the stirring shaft 18. The inside of the stirrer 15 is fed with circulating cooling water. The stirrer 15 is provided with a cooling water inlet 12 and a cooling water outlet 11. Fluorine packing seal 10; the ratio of the diameter of the ring-type stirring paddle 17 of the agitator 15 to the diameter of the kettle body 2 is 0.48:1, and the clamp between the center line of the ring pipe of the ring-type stirring paddle 17 of the agitator 15 and the stirring shaft 18 The angle is 3°; the ring-type stirring paddle 17 and the stirring shaft 18 are connected by detachable countersunk screws 22; the lower part of the stirring shaft 18 and the ring-type ...

Embodiment 2

[0021] Embodiment 2 is basically the same as Embodiment 1, except that the ratio of the diameter of the ring-type stirring paddle 17 of the stirrer 15 to the diameter of the kettle body 2 is 0.45:1, and the center of the ring pipe of the ring-type stirring paddle 17 of the stirrer 15 is 0.45:1. The angle between the line and the central line of the stirring shaft 18 is 4°;

[0022] The kettle body 2 has a volume of 130 cubic meters, an aspect ratio of 2.6, a height of 30 meters, and a nominal diameter of 4.0 meters.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com