FCC kaolin preparation method

A technology of kaolin and stirring rods, which is applied in the direction of chemical instruments and methods, catalyst activation/preparation, mixers, etc. It can solve the problems of complex mechanism and no consideration of stirring in the space of rotating blades, etc., and achieve the effect of speeding up the progress of stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the examples, but the present invention is not limited in any way, and any transformation or substitution made based on the teaching of the present invention belongs to the protection scope of the present invention.

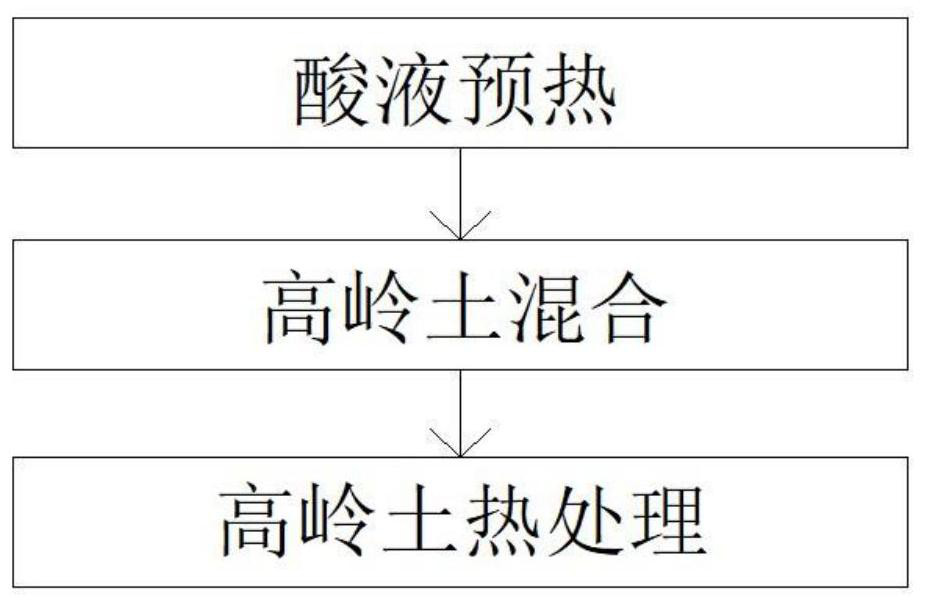

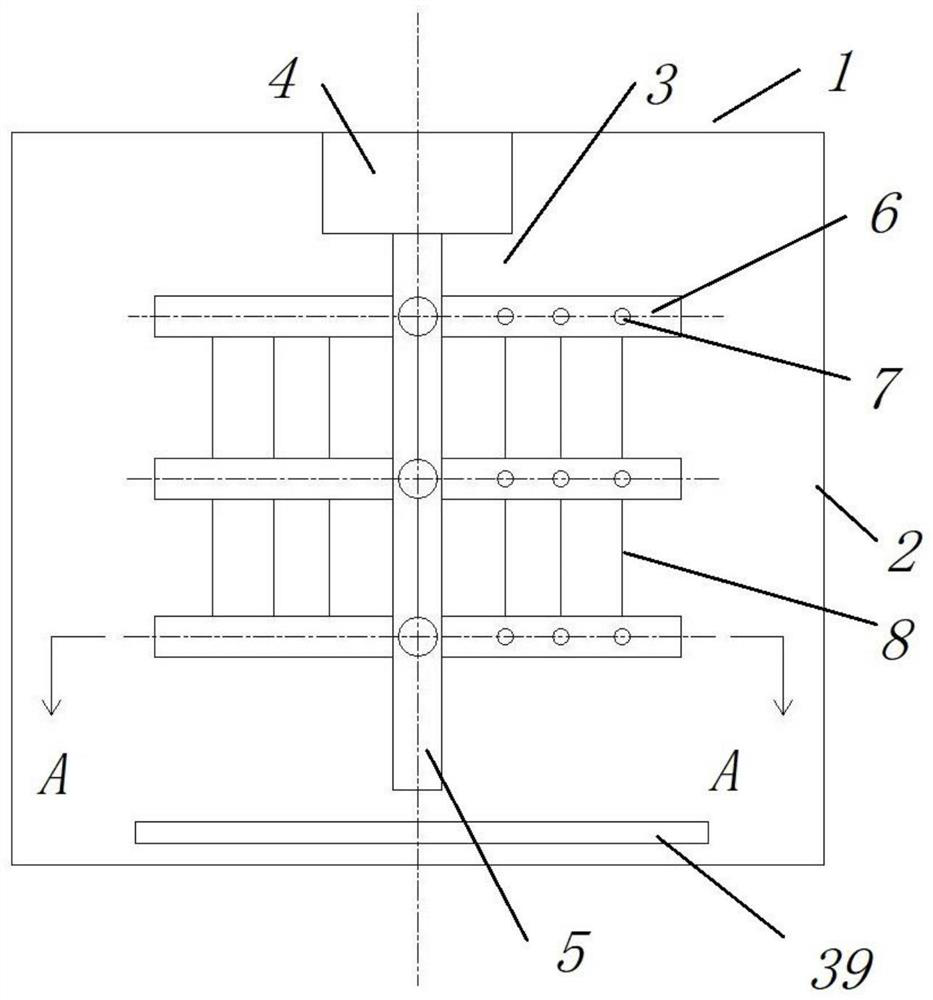

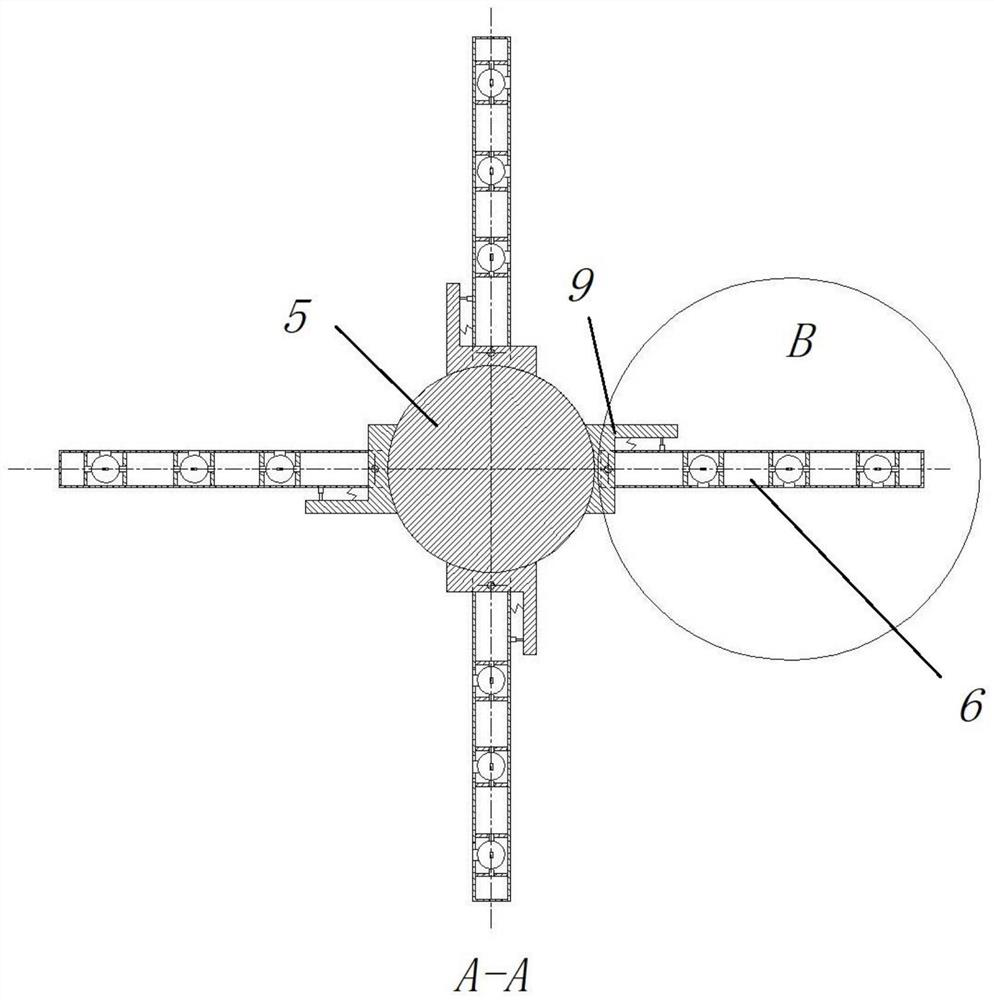

[0042] A kind of FCC kaolin preparation method, such as figure 1 shown, including the following steps:

[0043] (1) Acid solution preheating

[0044] According to the amount of kaolin to be prepared, add the calculated acid solution into the mixing drum 2 of the stirring device 1, heat the resistance wire 39, and then make the stirring mechanism 3 stir the acid solution, so that the acid solution can be heated evenly , after the temperature of the acid solution reaches the first predetermined temperature, stop the heating of the stirring mechanism 3 and the heating resistance wire 39;

[0045] (2) Kaolin mixture

[0046] Add the kaolin in the mixing drum 2, start the stirring mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com