Milk stirring and mixing drum with bidirectional driving mechanism

A two-way drive, stirring and mixing technology, applied in the direction of shaking/oscillating/vibrating mixers, mixers, mixer accessories, etc., can solve the problems of poor mixing effect, low mixing efficiency, and long time required for uniform mixing to achieve the best mixing effect Good, saving mixing time and speeding up the mixing progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

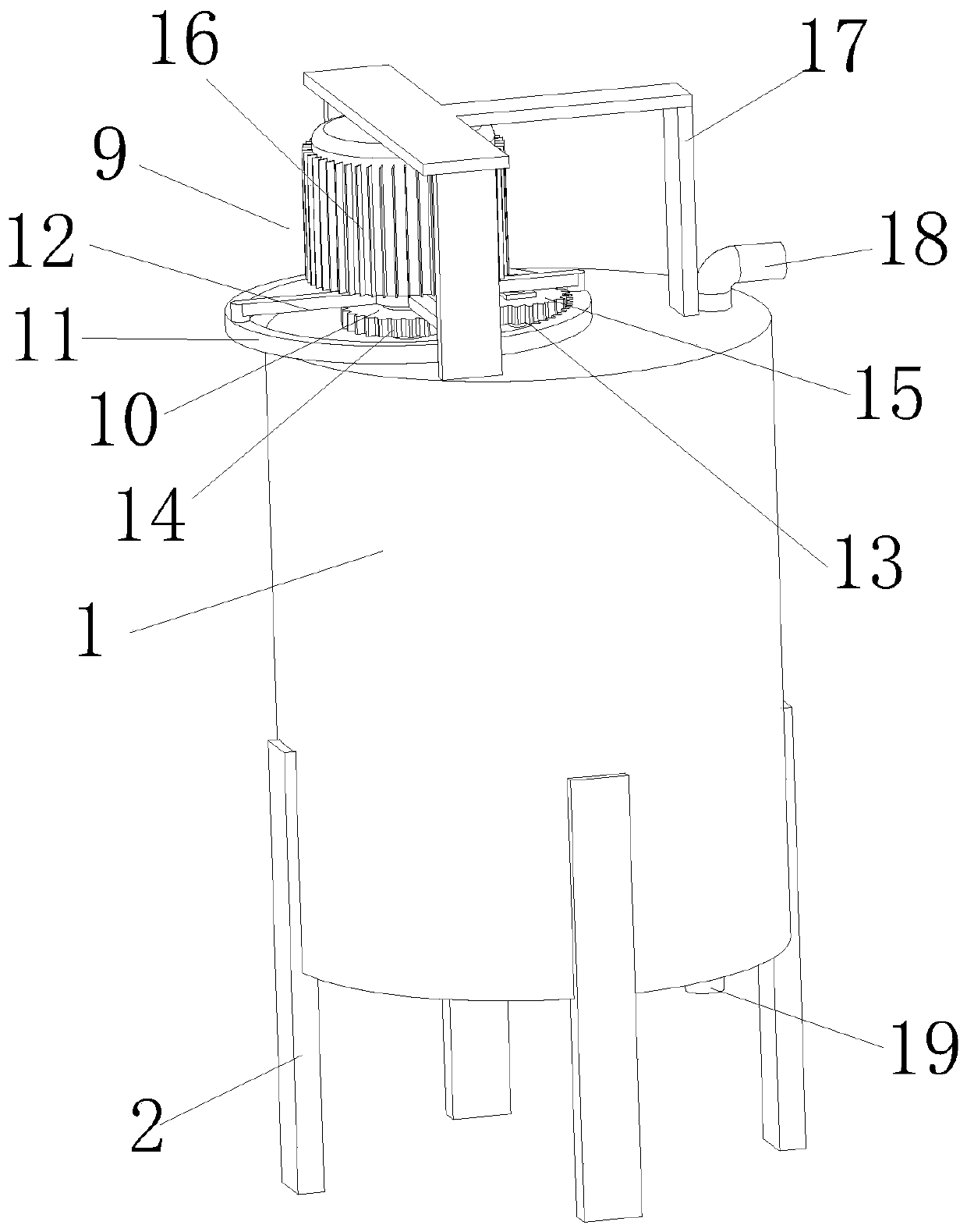

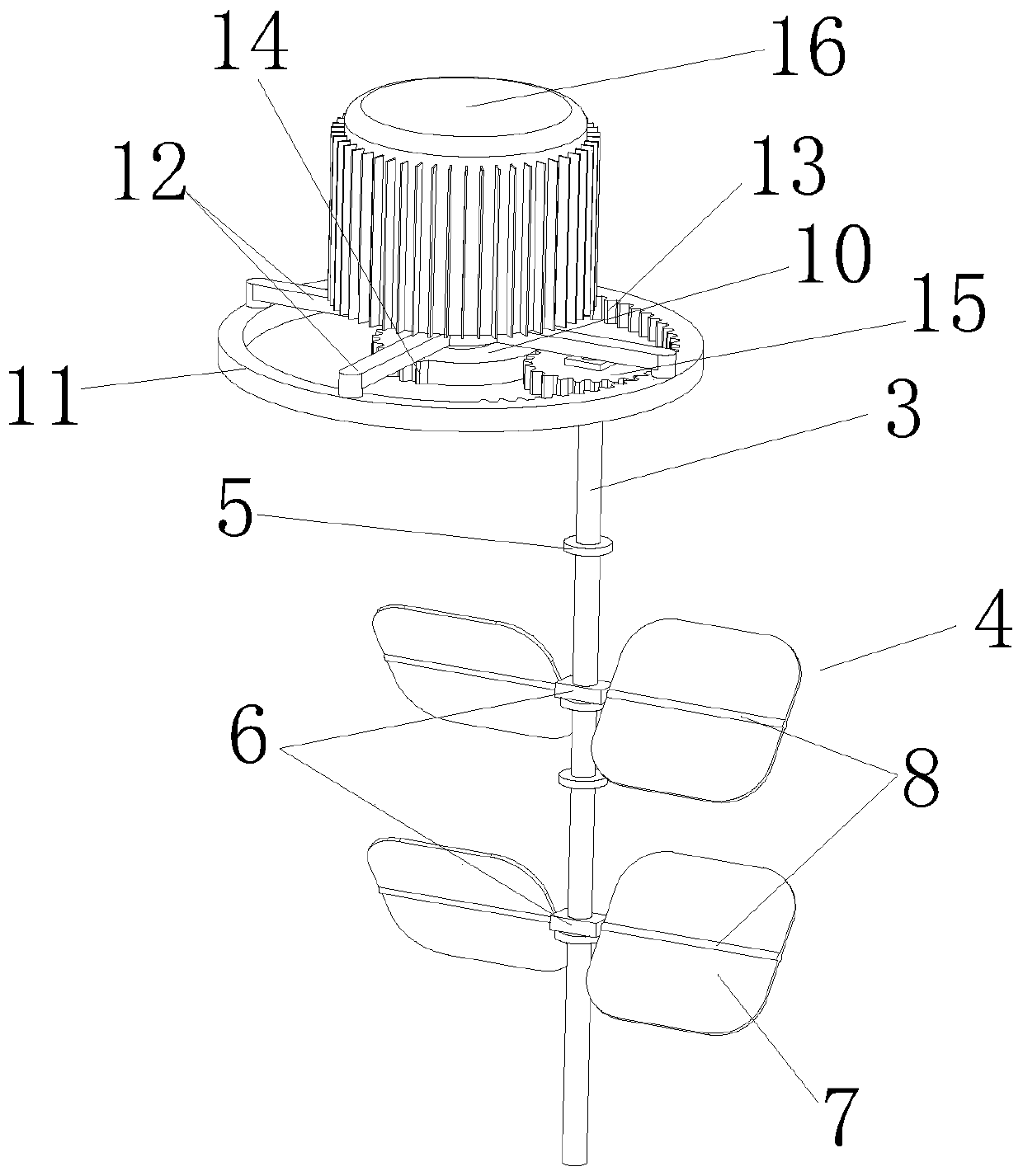

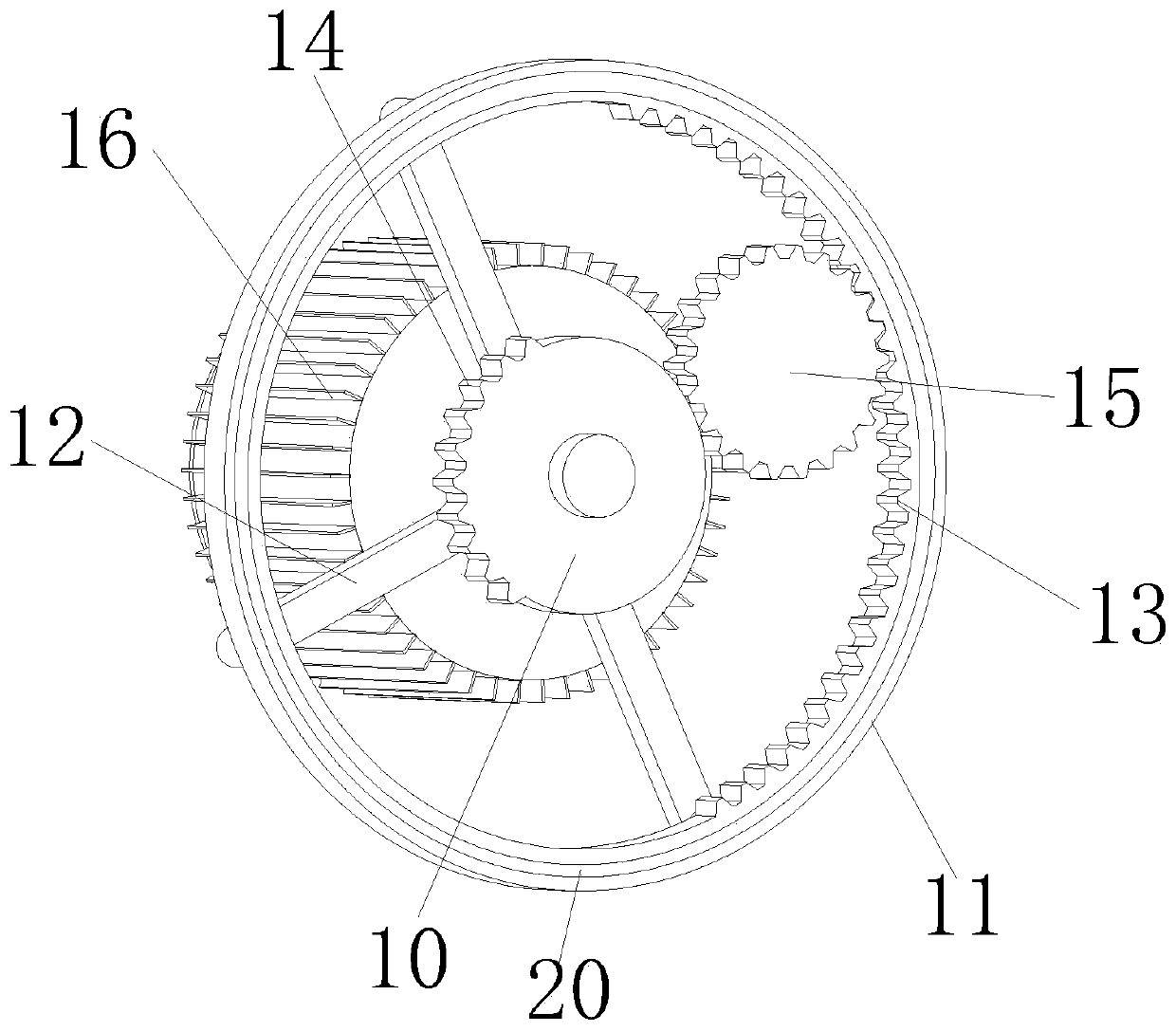

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a milk stirring mixing drum provided with a two-way drive mechanism includes a cylinder body 1 and a support frame 2 for supporting the cylinder body 1. The cylinder body 1 is provided with a rotating shaft 3 that can only rotate itself, and the rotating shaft 3 is equipped with two groups of longitudinally distributed stirring mechanisms 4, each group of stirring mechanisms 4 includes two longitudinally distributed limiting blocks 5, the limiting blocks 5 are fixedly arranged on the rotating shaft 3, and the two limiting blocks 5 There is a gap between them, and a slider 6 that is sleeved on the rotating shaft 3 and can only slide along the length direction of the rotating shaft 3 is set between the two limit blocks 5. The side of the sliding block 6 is fixedly connected with a The blades 7 are evenly distributed on the shaft 3 and arranged obliquely, and the blades 7 on the same slider 6 are distributed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com