A kind of low temperature preparation hot melt adhesive and its preparation method and a kind of adhesive tape

A hot-melt adhesive, low-temperature technology, used in adhesives, heat-activated films/sheets, non-polymer adhesive additives, etc. The effect of good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

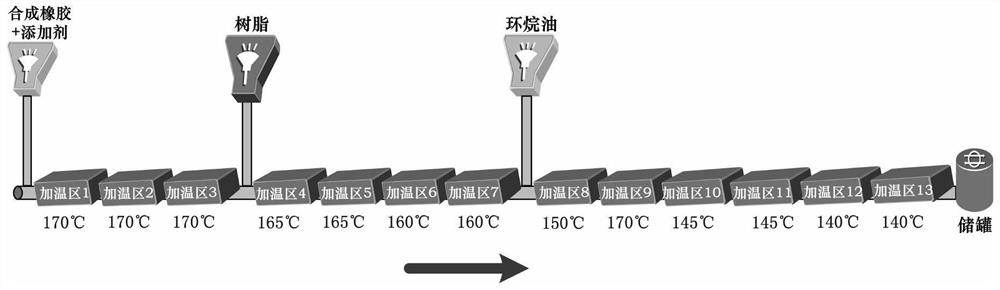

[0029] The invention provides a kind of preparation method of low-temperature preparation hot-melt adhesive, comprises the following steps:

[0030] Add synthetic rubber and additives to the feed port of the screw rubber machine, and after mixing in the first temperature zone, the second temperature zone and the third temperature zone, add naphthenic oil, and continue to process the fourth temperature zone, the fifth temperature zone temperature zone, the sixth temperature zone and the seventh temperature zone, and then add the resin, and then carry out the eighth temperature zone, the ninth temperature zone, the tenth temperature zone, the eleventh temperature zone, the twelfth temperature zone and the sixth temperature zone Mixing in thirteen temperature zones to obtain hot melt adhesives prepared at low temperature;

[0031] In terms of mass percentage, the raw material ratio for preparing the hot melt adhesive at low temperature is: 30-35% of synthetic rubber, 5-7% of addi...

Embodiment 1

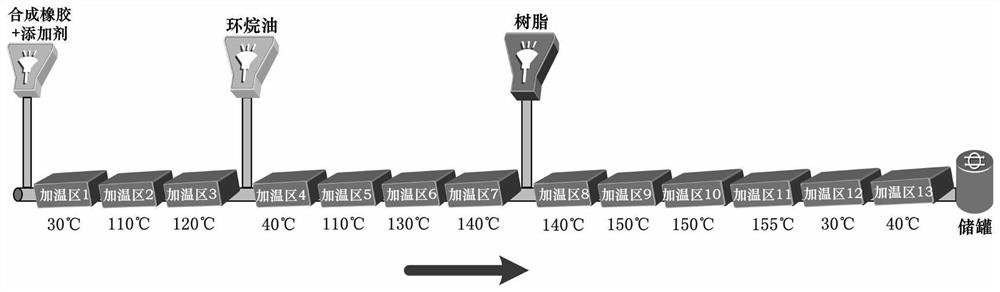

[0055] like figure 1 Shown is the process flow diagram of the present embodiment, and concrete steps are as follows:

[0056] Set the temperature of the thirteen temperature zones of the screw rubber machine, specifically: the temperature of the first temperature zone is 30°C, the temperature of the second temperature zone is 110°C, the temperature of the third temperature zone is 120°C, and the fourth temperature zone The temperature in the temperature zone is 40°C, the temperature in the fifth temperature zone is 110°C, the temperature in the sixth temperature zone is 130°C, the temperature in the seventh temperature zone is 140°C, the temperature in the eighth temperature zone is 140°C, and the temperature in the ninth temperature zone is 140°C. The temperature in the temperature zone is 150°C, the temperature in the tenth temperature zone is 150°C, the temperature in the eleventh temperature zone is 155°C, the temperature in the twelfth temperature zone is 30°C, and the te...

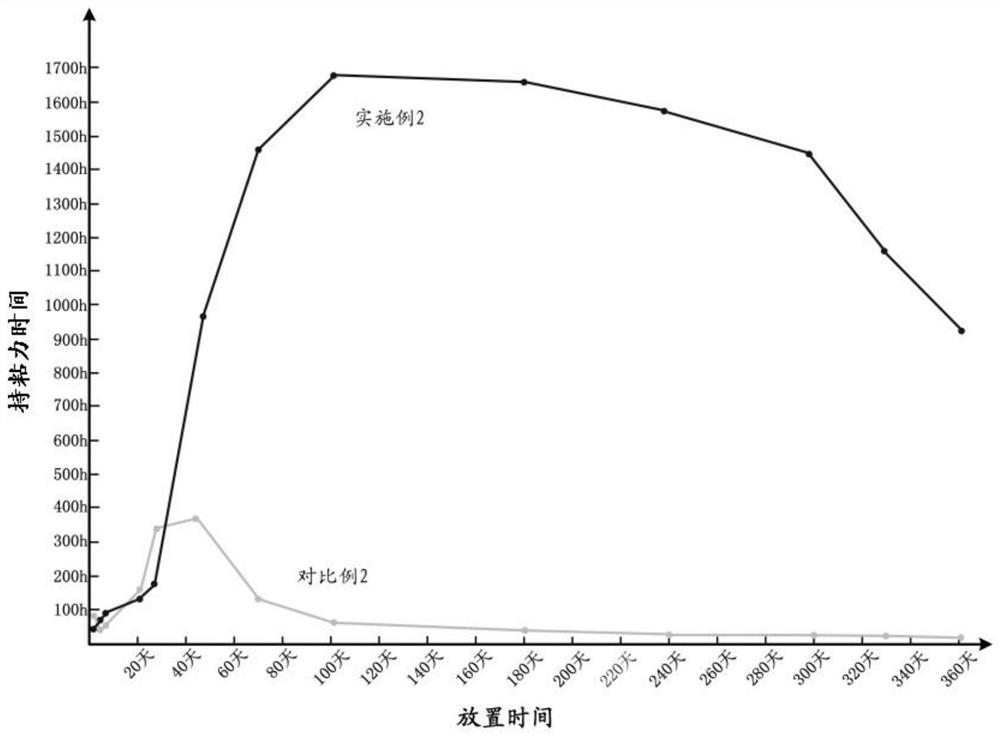

Embodiment 2

[0069] Polyethylene particles are melted and coated on a 70-mesh cloth-based substrate (500m 2 ), the amount of coating is 87.5±2.5g / m 2 , and then use the anilox roll transfer method to coat the silicon solution on the surface of the film to obtain a 70-mesh cloth-based substrate with a good coating and silicon; wherein the silicon solution is a mixture of silicon and toluene in a ratio of 1:80 according to the mass ratio Obtained, the amount of silicon on the silicon is 1.25±2.5g / m 2 ;

[0070] Coat 60kg of the hot melt adhesive prepared at low temperature obtained in Example 1 on the 70-mesh cloth-based substrate coated with film and silicon according to two coating methods, wherein the amount of primer coating is 70g / m 2 , surface glue coating amount is 35g / m 2 , and then rewinding and cutting in turn to obtain 300 rolls of cloth tape with a width of 48mm and a length of 30m, and paste the sample number and use glue to identify.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com