Device for improving desulfurization efficiency of circulating fluidized bed boiler and method for improving desulfurization efficiency

A technology of circulating fluidized bed and desulfurization efficiency, applied in fluidized bed combustion equipment, combustion method, fuel burned in molten state, etc., can solve the problem that limestone cannot fully contact with flue gas, limit the utilization rate of limestone, and limit desulfurization in the furnace Efficiency and other issues, to achieve the effect of improving specific surface area, increasing specific surface area, and fast calcination speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

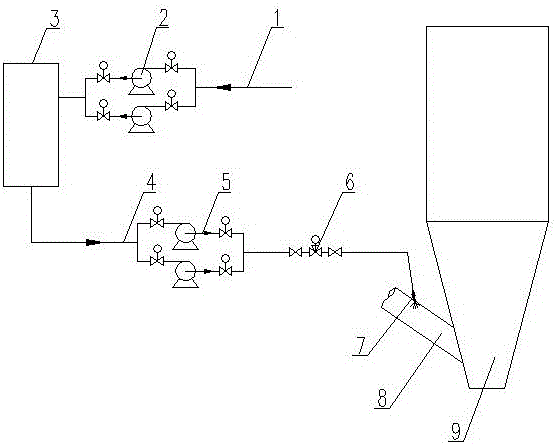

[0020] A device for improving the desulfurization efficiency of a circulating fluidized bed boiler, which consists of: a water supply pipeline 1, the inlet of the water supply pipeline is connected to the feedwater pump 2, and the water supply pump is connected to the inlet of the water storage tank 3 through the water supply pipeline. The outlet of the water storage tank is connected to one end of the booster water pump 5 through the water supply pipeline 4, and the other end of the booster water pump is connected to the flow regulating valve 6, and the flow regulating valve is connected to the humidifying water spray gun 7 through the water supply pipeline, so The humidifying water spray gun is installed in the return leg 8, and the return leg is installed below the fluidized bed boiler 9.

Embodiment 2

[0022] According to the device for improving the desulfurization efficiency of circulating fluidized bed boilers described in Example 1, the water supply pipeline is DN125mm, the flow rate of the water supply pump is 50m3 / h, the volume of the water storage tank is 100 m3, and the water supply The pipeline is DN40mm, the flow rate of the booster pump is 2 m3 / h, and the flow adjustment range of the flow regulating valve is 0.5-2 m3 / h.

Embodiment 3

[0024] A method for improving the desulfurization efficiency device and desulfurization efficiency of a circulating fluidized bed boiler described in Embodiment 1-2. This method is first to pressurize the water in the water storage tank through a booster water pump, and then enter the Humidifying water spray gun, the humidifying water spray gun is sprayed into the return leg under the fluidized bed boiler, and the water evaporates into water vapor in the return leg, providing a high water vapor environment for the calcination of limestone , so as to improve the desulfurization reaction speed and improve the utilization rate of limestone; the water storage tank can meet the injection water consumption of a single unit for 2 days, the water consumption is about 2t / h, and the water supply time is 2 hours;

[0025] Water is supplied to the water storage tank through the water supply pipeline and the water supply pump. The water in the water storage tank is pressed into the water su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com