Kiln nose ring structure of cement rotary kiln

A technology of cement rotary kiln and kiln mouth, which is applied in the processing of building materials and the separation of sludge. It can solve the problems of uneven heating, easy material leakage at the kiln tail, and easy over-burning of materials, etc., to improve the calcination speed and kiln speed. Improve and improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

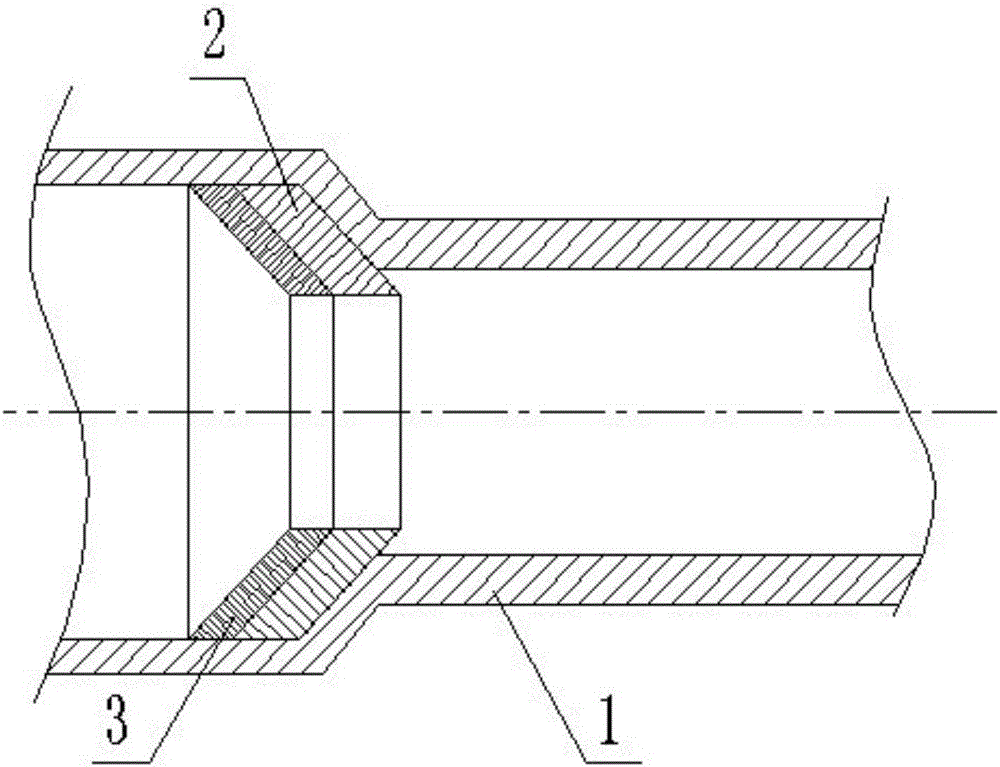

[0020] Example 1: Remove the original pouring material to expose the base layer, and then use ribs with a thickness of 2cm to splice the base layer into a circular kiln mouth ring body 1, and ensure that there are several square grids between the ribs grid, and then fill the grid with the above-mentioned formula and ratio of castables. Before filling the castables, take the raw materials of each component in proportion and mix them; A layer of lightweight pouring layer 3 is poured on the surface of the plate layer 2. The lightweight pouring layer 3 is the pouring layer 2 from which heat-resistant steel fibers and refractory glass fibers have been removed. The lightweight pouring layer 3 can be dried.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com