Vibration-magnetic coupling fluidized bed flue gas desulfurization reactor

A fluidized bed and reactor technology is applied in the field of fluidized bed flue gas desulfurization reactors to achieve the effects of improving desulfurization efficiency, long time and reducing fluidization speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

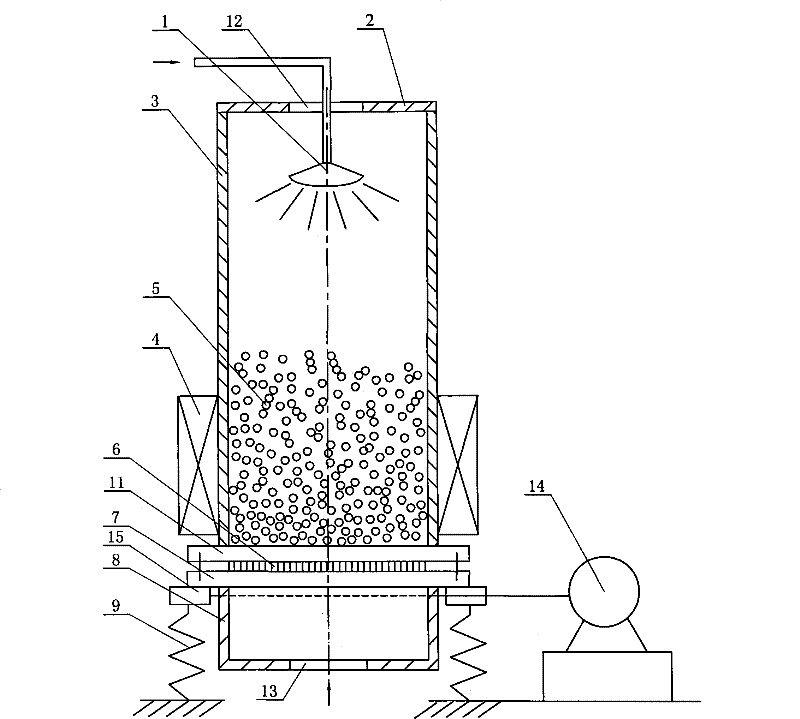

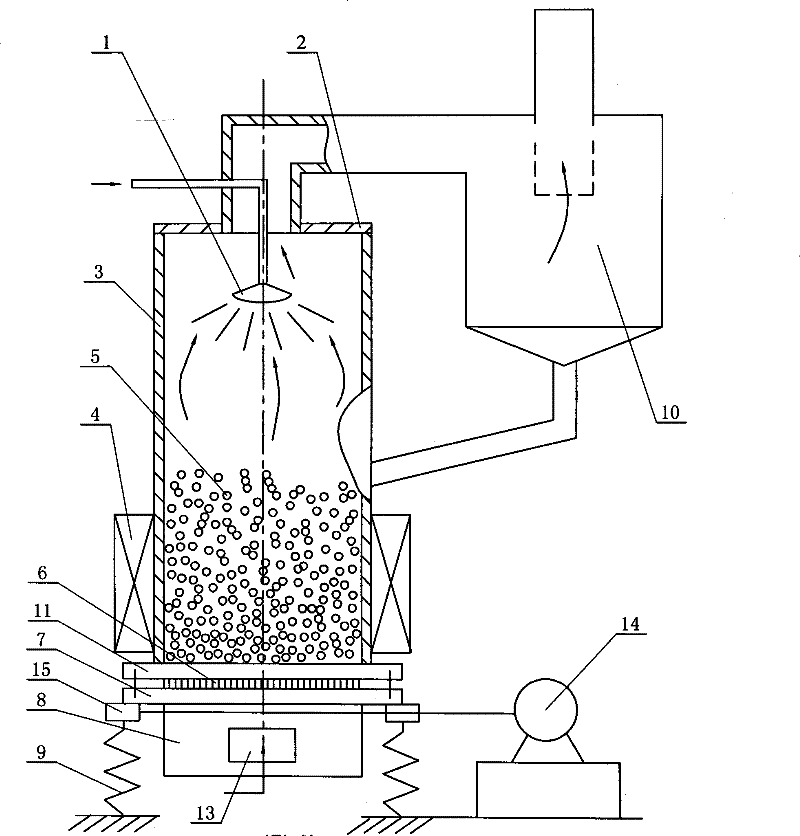

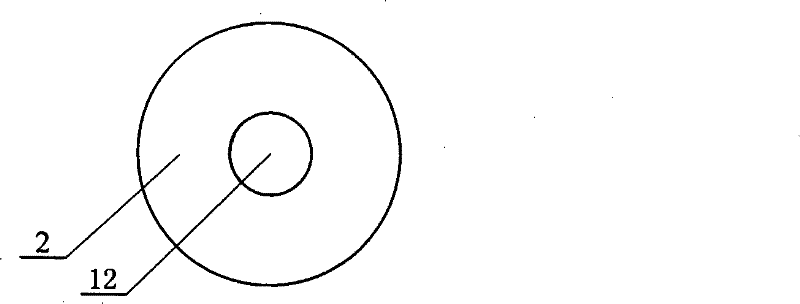

[0011] Specific implementation mode one: combine Figure 1 ~ Figure 3 To illustrate this embodiment, the flue gas desulfurization reactor of this embodiment includes a fluidized bed, an atomizing nozzle 1, a magnetic spiral coil 4, and an air box 8; plate 6, an upper fixed frame plate 11, a lower fixed frame plate 7, and a magnetic bed material 5; the annular upper cover 2 is fixedly connected to the upper end surface of the cylinder body 3, and the central hole of the annular upper cover 2 is a smoke outlet 12, The upper fixed frame plate 11 and the lower fixed frame plate 7 are stacked together and fixed between the lower end surface of the cylinder body 3 and the upper end surface of the bellows 8, the cylinder body 3 is equipped with a magnetic bed material 5, and the air distribution The plate 6 is fixed between the upper fixed frame plate 11 and the lower fixed frame plate 7, the flue gas inlet 13 is provided under the bellows 8, and the atomizing nozzle 1 is hoisted in ...

specific Embodiment approach 2

[0012] Specific implementation mode two: combination Figure 1 ~ Figure 3 To illustrate this embodiment, the cylinder body 3, the annular upper cover 2, the air distribution plate 6, the upper fixed frame plate 11, and the lower fixed frame plate 7 of this embodiment are all made of non-magnetic materials, which is beneficial to the smooth reaction of desulfurization. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0013] Specific implementation mode three: combination figure 1 , figure 2 The present embodiment is described. The flue gas inlet 13 of the present embodiment is arranged on the bottom plate of the wind box 8 or on the side wall of the wind box 8 , as required. Other compositions and connections are the same as those in Embodiment 1.

[0014] The working principle is: sulfur-containing flue gas enters the reactor filled with magnetic powder through the air distribution plate 6, and the desulfurizer enters the reactor from above the fluidized bed through the atomizing nozzle. The desulfurizing agent droplets react chemically with SOx in the rising flue gas, and the unreacted desulfurizing agent falls and covers the magnetic particles, forming a desulfurizing agent reaction layer to continue to react with SOx. When the gas velocity or amplitude is large, the magnetic particles and desulfurizer are carried out of the reactor by the flue gas, and enter the separation device 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com