A method for removing slag from molten iron

A technology of molten iron and ladle, applied in the direction of manufacturing tools, mechanical cleaning, casting equipment, etc., can solve the problems affecting the stability of metallurgical effects, serious environmental pollution, poor working environment, etc., to save the workshop area, reduce investment and maintenance Cost, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

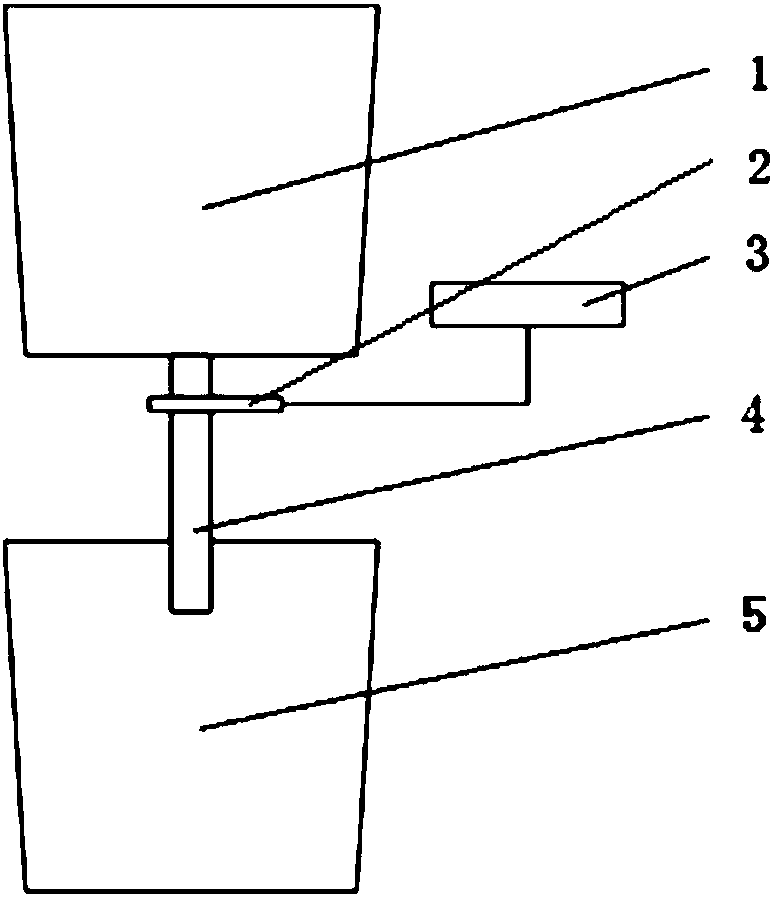

Image

Examples

Embodiment 1

[0028] A steel mill with wide and thick plates adopts a converter for steelmaking. The nominal capacity of the converter is 100 tons. A newly built ladle with a sliding plate mechanism is built. The ladle slag line is 3.0m high and the radius is 1.4m. Hoisted to the tap position, the crane said that the empty ladle weighed 55.0 tons, and the torpedo tank molten iron was accepted; the desulfurization of the original molten iron was sprayed with granular magnesium, and the slag removal method was the slag removal process.

[0029] The granular magnesium injection desulfurization process is used for treatment in the deep desulfurization mode. After the injection, the sulfur content of the molten iron is 0.003%, and the weight displayed by the hoisting crane is 150.1 tons, that is, the total weight of the molten iron and iron slag in the ladle is 95.1 tons;

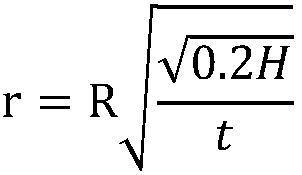

[0030] Install the long nozzle with a radius of 35mm on the ladle equipped with a sliding plate mechanism, hang it above the...

Embodiment 2

[0037] A special steel plant uses an electric furnace for steelmaking. The nominal capacity of the electric furnace is 80 tons. The off-line ladle is equipped with a slide mechanism. The ladle slag line is 2.8m high and the radius is 1.14m. It shows that the weight of the empty ladle is 47.0 tons, and the torpedo tank molten iron is undertaken; the desulfurization of the original molten iron is by spraying granular magnesium, and the slag removal method is the slag removal process.

[0038] The granular magnesium injection desulfurization process is used for treatment in the deep desulfurization mode. After the injection, the sulfur content of the molten iron is 0.004%, and the weight displayed by the hoisting crane is 107.1 tons, that is, the total weight of the molten iron and iron slag in the ladle is 60.1 tons;

[0039] Install the long nozzle with a radius of 40mm on the ladle, hang it above the ordinary molten iron ladle, open the slide plate, let the molten iron flow nat...

Embodiment 3

[0046]A coil steel plant uses a converter for steelmaking. The nominal capacity of the converter is 300 tons. A new molten iron ladle with a sliding plate mechanism is newly built. The height of the ladle slag line is 4.2m and the radius is 1.8m. In consideration of time, the long nozzle radius is designed to be 60mm. After the preparatory work was completed according to the baking system, it was hoisted to the molten iron car. The crane said that the empty ladle weighed 78.0 tons, and it was used for tapping the molten iron from the blast furnace.

[0047] After the molten iron is pulled back to the desulfurization station, the KR desulfurization process is used to treat it in the deep desulfurization mode. After desulfurization, the sulfur content of the molten iron is 0.001%, and the weight displayed by the hoisting crane is 349.1 tons, that is, the total weight of the molten iron and iron slag in the ladle is 271.1 tons;

[0048] The long nozzle is installed on the ladle e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com