An automatic injection device for pills applied to uhp lamp bulbs

An automatic injection and bulb technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of increased production costs, low injection efficiency, inaccurate injection control, etc., to achieve stable automation control and reasonable design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

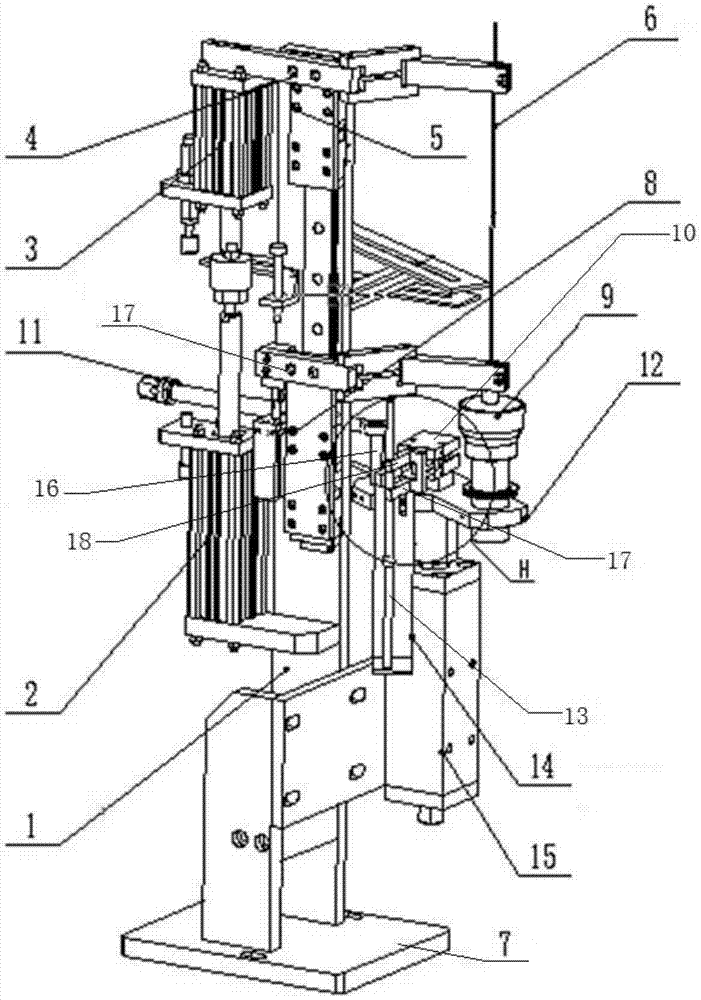

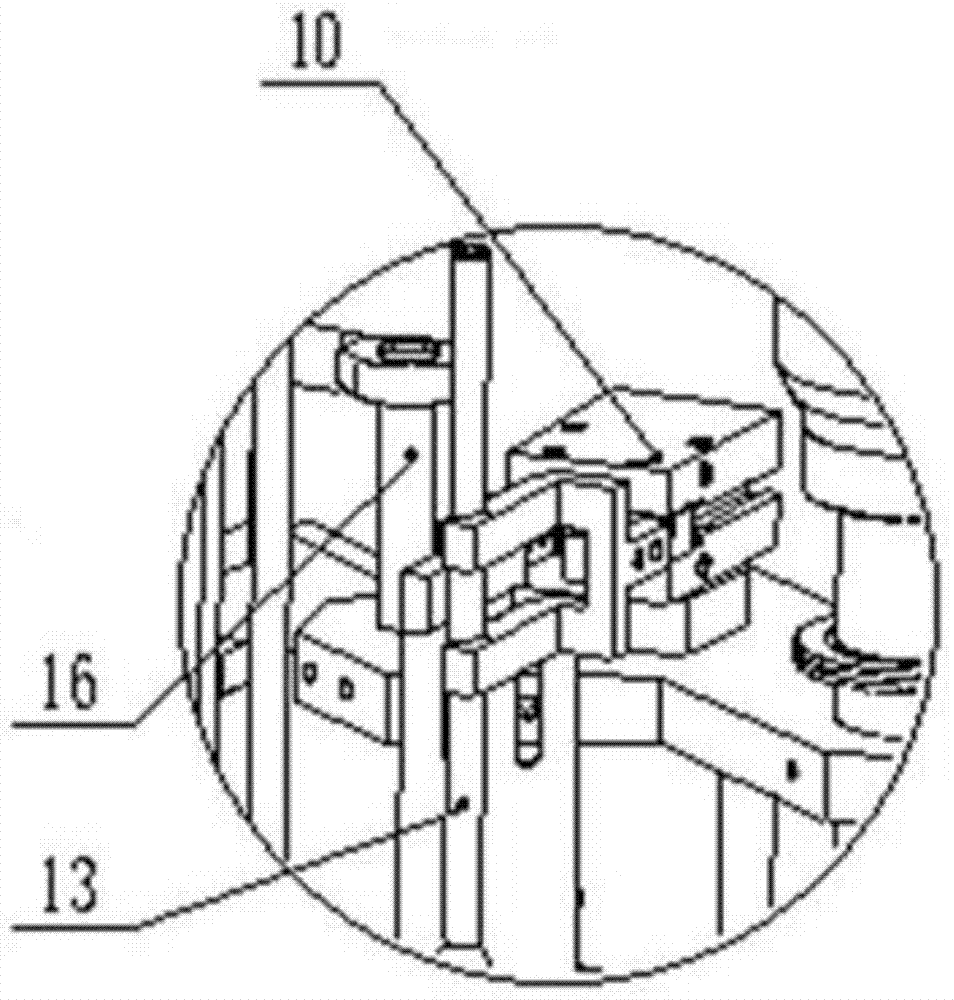

[0016] Such as figure 1 and figure 2 The shown automatic pill injection device applied to UHP lamp bulbs includes a bottom plate 7, a vertical support plate 1 arranged on the bottom plate 7, and a jaw cylinder installation block 15 arranged on the vertical support plate 1, And the jaw cylinder 10 that is arranged on the jaw cylinder mounting block 15, and the third cylinder 11 that is arranged on the vertical support plate 1, and the connecting shaft pin 16 that is connected with the third cylinder 11, and is connected with the connecting shaft pin 16 The push wobble plate 12, and the pill storage cup 9 arranged at the end of the push wobble plate 12, and the clamping block 18 connected with the jaw cylinder 10, and the UHP connected with the push wobble plate 12 and positioned under the clamp block 18 Lamp bulb positioning plate 14, and the first cylinder 2 that is arranged on the vertical support plate 1, and the second cylinder 3 that is arranged on the vertical support p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com