A molding die device for u-shaped strip material

A molding die, U-shaped technology, applied in the direction of molding tools, storage devices, feeding devices, etc., can solve the problems of uneven upper and lower surfaces, poor overall flatness, and low degree of automation, so as to improve flatness and save money. Cost, effect of dispersing molding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

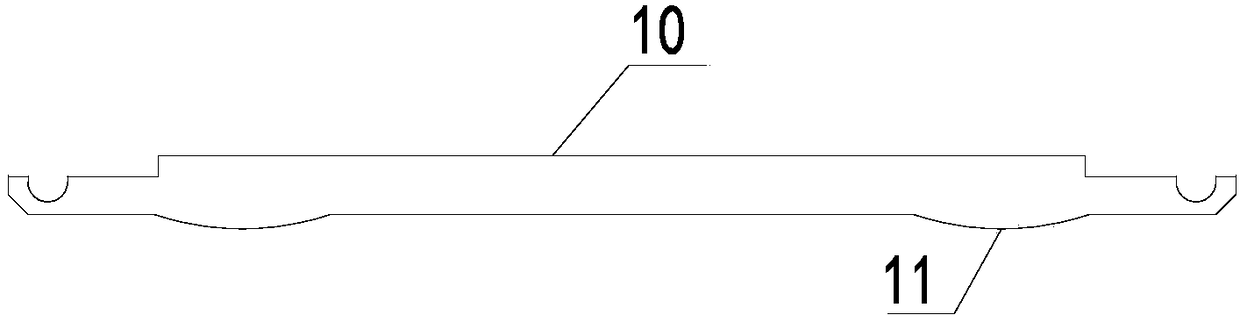

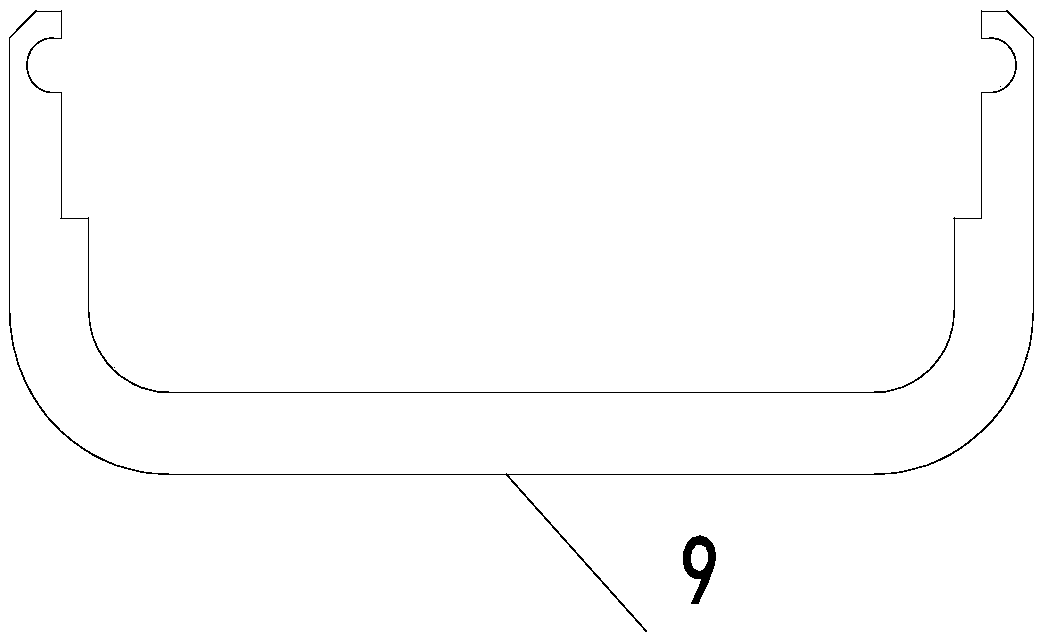

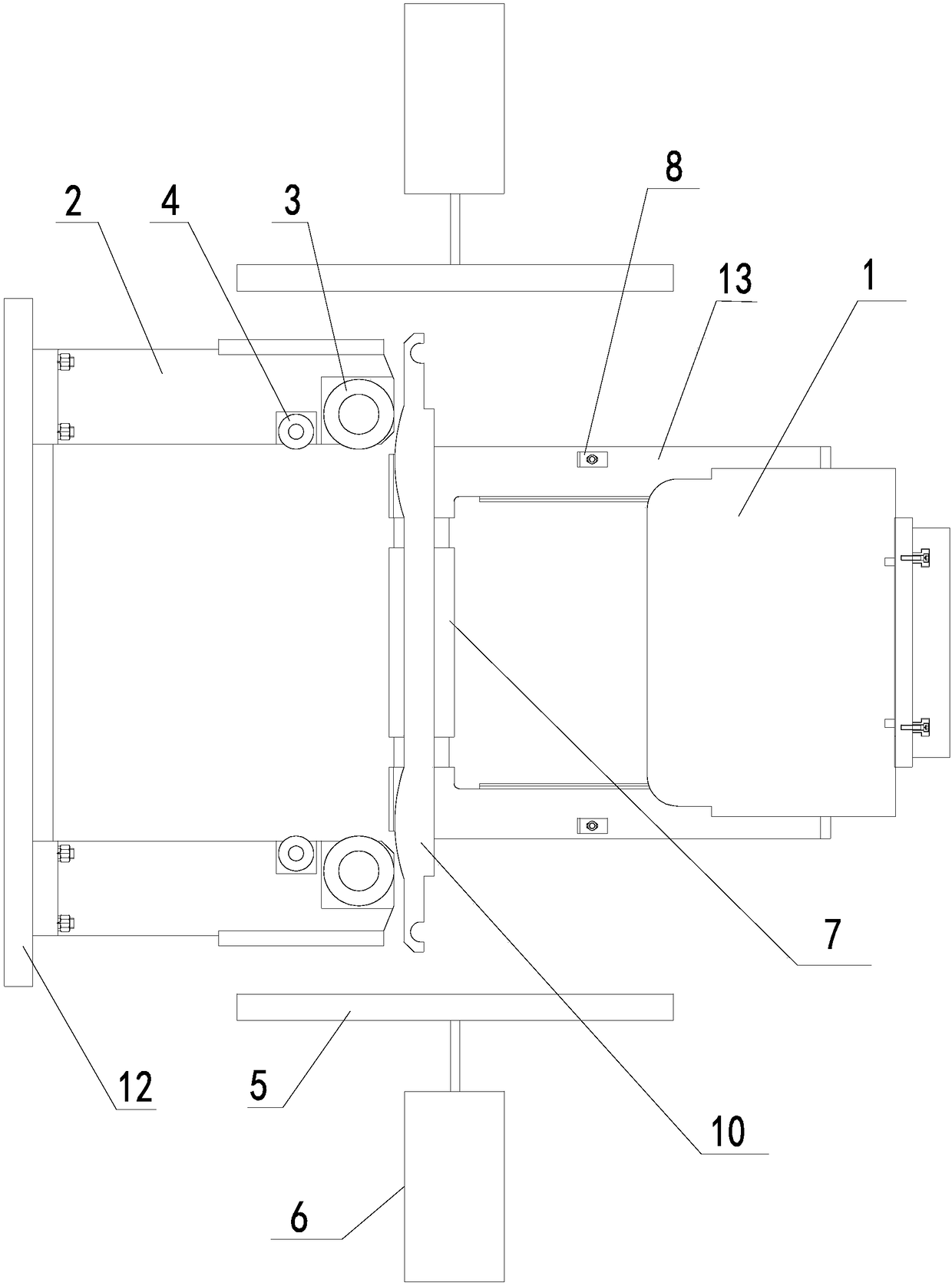

[0023] see Figure 1 to Figure 5 , this embodiment discloses a forming die device for U-shaped strips, the U-shaped strips 9 can be, for example, the upper mast of a forklift or other similar products. The forming die device includes a concave die and a punch 1 arranged horizontally side by side. Both the punch 1 and the concave die are movable molds. The working surface of the punch 1 coincides with the inner wall of the U-shaped strip material 9. The punch 1 is set On the base 13, an L-shaped positioning plate 7 is also arranged on the base 13. The positioning plate 7 is composed of a horizontal bottom plate and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com