RH refining desulphurization process of non-oriented electrical steel

A technology of oriented electrical steel and desulfurization process, which is applied in the field of steelmaking, can solve the problems of low desulfurization rate of low-fluorine desulfurizers, corrosion of RH equipment, serious corrosion of equipment, etc., to reduce oxidation, prevent resulfurization, and increase alkalinity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The process of the present invention is as follows: after the RH enters the station, the lifting gas flow rate is set to 1200NL / min, and the lifting gas flow rate is increased to 1600NL / min after 3 minutes. After the vacuum degree is reduced to 2.0mba, oxygen is blown to carry out forced decarburization. After the oxygen blowing is completed, the vacuum degree is controlled below 2.0mba, and natural decarburization is started, and the natural decarburization time is guaranteed to be 20 minutes. After vacuum decarburization, aluminum is added for deoxidation. Firstly, low-carbon ferrosilicon is used for silicon alloying, and then the desulfurizer is put into the vacuum chamber through the RH alloy silo, and the desulfurizer is added in two batches. The test furnace cycle time is 10min to 15min.

[0025] It is carried out on the RH refining furnace of the slab production line of an iron and steel enterprise, and the test steel is non-oriented electrical steel. The produ...

comparative example 1

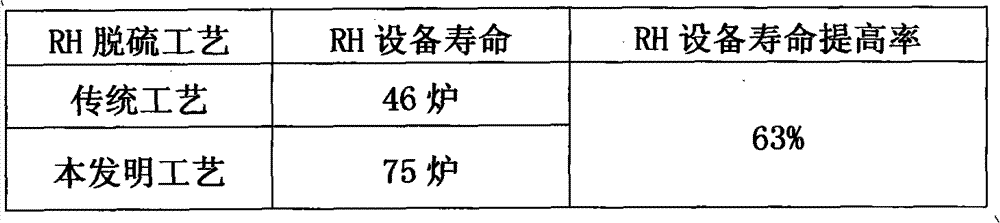

[0027] It was carried out on the RH refining furnace of the slab production line of the same steel plant and steel company, and the test steel was non-oriented electrical steel. Hot metal pretreatment desulfurization → LD → slag blocking tapping → LF → RH decarburization → continuous casting production process. After the RH enters the station, set the lifting gas flow rate to 1200NL / min, and increase the lifting gas flow rate to 1600NL / min after 3 minutes. After the vacuum degree is reduced to 2.0mba, oxygen is blown to carry out forced decarburization. After the oxygen blowing is completed, the vacuum degree is controlled below 2.0mba, and natural decarburization is started, and the natural decarburization time is guaranteed to be 20 minutes. No desulfurization treatment is carried out, and the ladle top slag out of the ladle RH is not modified. The sulfur content of the finished product is above 65ppm, and the RH process has no desulfurization ability. RH insert tube life ...

comparative example 2

[0029] It was carried out on the RH refining furnace of the slab production line of the same steel plant and steel company, and the test steel was non-oriented electrical steel. Adopt hot metal pretreatment desulfurization → LD → slag retaining and tapping → LF → RH decarburization, desulfurization → continuous casting production process. After the RH enters the station, set the lifting gas flow rate to 1200NL / min, and increase the lifting gas flow rate to 1600NL / min after 3 minutes. After the vacuum decarburization is completed, aluminum is added for deoxidation, and FeO+MnO in the top slag is not controlled. The pre-melted traditional desulfurizer is used, and the addition method is the direct addition method of the alloy silo. The particle size of the desulfurizer is controlled at 3-5mm, and the addition amount is 3-5Kg / t. While using low-carbon ferrosilicon for silicon alloying, the desulfurizer is added at one time. After adding the desulfurizer, the vacuum cycle time t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com