Efficient desulfurizer and preparation and use methods thereof

A desulfurization agent and high-efficiency technology, applied in the field of metallurgical desulfurization, can solve the problems of low utilization rate of pure magnesium, and achieve the effects of desulfurization, increase of alkalinity, and increase of desulfurization capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

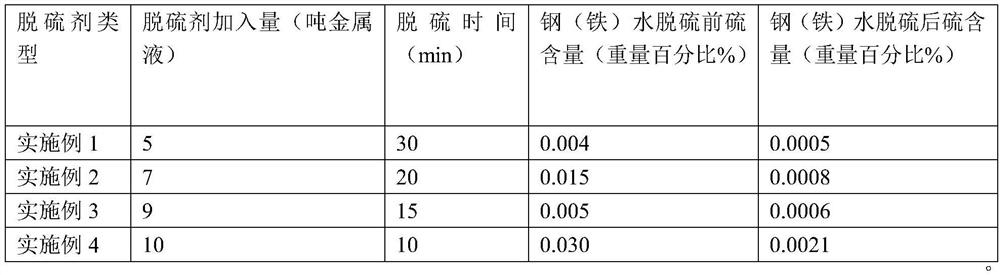

Examples

Embodiment 1

[0037] 1) Weigh raw materials according to the following percentage by weight: Mg 3 N 2 22%, CaO 52%, carboxymethyl cellulose 2% (binder), and the rest is iron powder.

[0038] 2) Mg 3 N 2 and CaO were put into the crusher for crushing, Mg 3 N 2 and CaO are broken into particles with a particle size of less than 0.1mm.

[0039] 3) To prevent Mg 3 N 2 and CaO reduce the activity due to water absorption, using silicone oil for Mg 3 N 2 Spray treatment with CaO particles to form a protective film.

[0040] 4) Mg 3 N 2 , CaO, iron powder, and binder are mechanically mixed in a mixer. The mixing time was 2.5 hours.

[0041] 5) The ball is pressed by a roller press. The pressure of the roller press is 600Kg / cm 2 , the spherical particle size is 10mm.

[0042] 6) The selected products are dried, packaged and ready for use. The drying temperature is 130° C., and the drying time is 2 hours.

Embodiment 2

[0044] 1) Weigh raw materials according to the following percentage by weight: Mg 3 N 2 25%, CaO 42%, carboxymethyl cellulose 2.3% (binder), and the rest is iron powder.

[0045] 2) Mg 3 N 2 and CaO were put into the crusher for crushing, Mg 3 N 2 and CaO are broken into particles with a particle size of less than 0.1mm.

[0046] 3) To prevent Mg 3 N 2 and CaO reduce the activity due to water absorption, using silicone oil for Mg 3 N 2 Spray treatment with CaO particles to form a protective film.

[0047] 4) Mg 3 N 2 , CaO, iron powder, and binder are mechanically mixed in a mixer. The mixing time was 2.6 hours.

[0048] 5) The ball is pressed by a roller press. The pressure of the roller press is 610Kg / cm 2 , The spherical particle size is 15mm.

[0049] 6) The selected products are dried, packaged and ready for use. The drying temperature is 135° C., and the drying time is 2.2 hours.

Embodiment 3

[0051] 1) Weigh out the following raw materials by the following weight percentages: Mg 3 N 2 27%, CaO 40%, carboxymethyl cellulose 3% (binder), and the rest is iron powder.

[0052] 2) Mg 3 N 2 and CaO were put into the crusher for crushing, Mg 3 N 2 and CaO are broken into particles with a particle size of less than 0.1mm.

[0053] 3) To prevent Mg 3 N 2 and CaO reduce the activity due to water absorption, using silicone oil for Mg 3 N 2 Spray treatment with CaO particles to form a protective film.

[0054] 4) Mg 3 N 2 , CaO, iron powder, and binder are mechanically mixed in a mixer. The mixing time was 2.6 hours.

[0055] 5) The ball is pressed by a roller press. The pressure of the roller press is 650Kg / cm 2 , the spherical particle size is 20mm.

[0056] 6) The selected products are dried, packaged and ready for use. The drying temperature is 140° C., and the drying time is 2.8 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com