Direct forming manufacturing method of metal-based multilayer/gradient composite board and process unit of direct forming manufacturing method

A composite plate and manufacturing method technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of high energy consumption, low efficiency of thermal diffusion methods, etc., and achieve the effect of strengthening solid solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Preferred embodiments of the present invention are described in detail as follows:

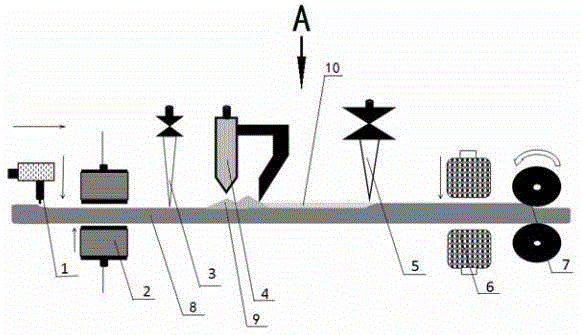

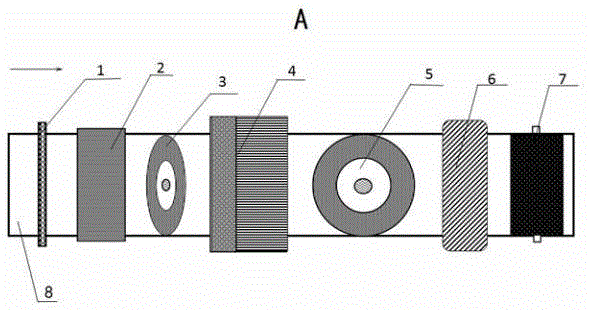

[0030] In this example, see figure 1 and figure 2 , a process device for implementing the direct forming manufacturing method of metal-based multilayer / gradient composite plates, its processing unit includes a chemical cleaning unit 1 arranged in sequence along the extending direction of the base plate 8, a base plate surface treatment device, and a powder laying device 4 , melting and sintering device, cold / hot roll end composite sheet end control device 7, all equipment and devices are installed and arranged according to the direct forming manufacturing process of metal-based multi-layer / gradient composite sheet, and the chemical cleaning unit 1 cleans the surface of the base sheet 8 Chemical cleaning, removing scale and rust on the surface of the base plate 8, the base plate surface treatment device includes a surface treatment electromagnetic induction heating device 2 and a laser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com