Method for reducing inclusion content of casting blank

A technology of inclusions and content, which is applied in the field of reducing the content of inclusions in the slab in the continuous casting process, can solve problems such as slab defects, waste products, and increased oxide inclusions, so as to reduce slab defects and waste products and improve product quality. mass, the effect of avoiding inhalation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

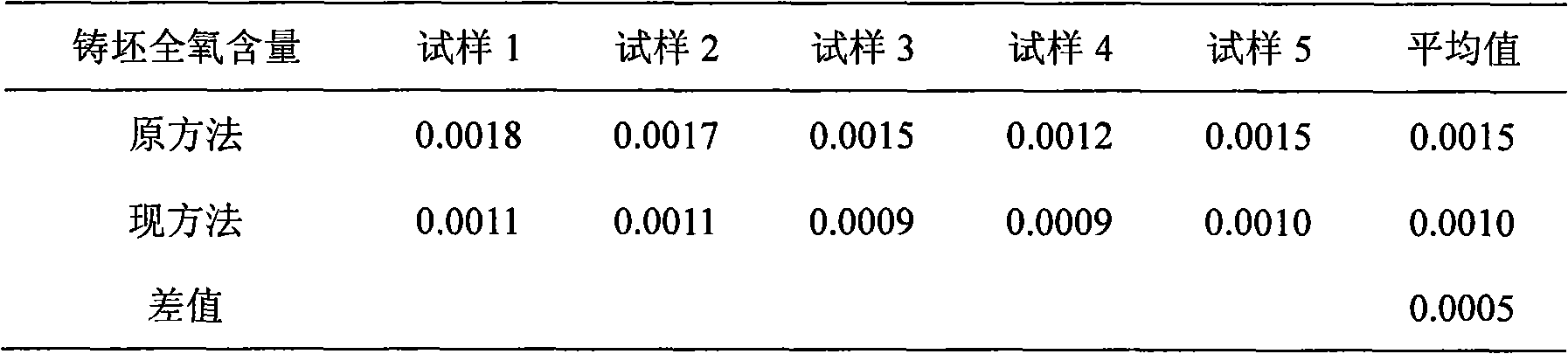

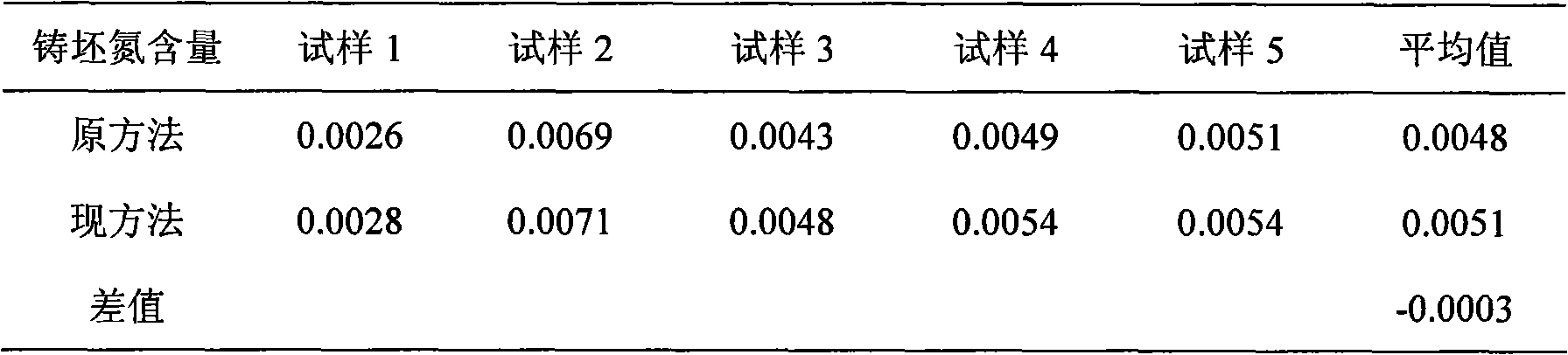

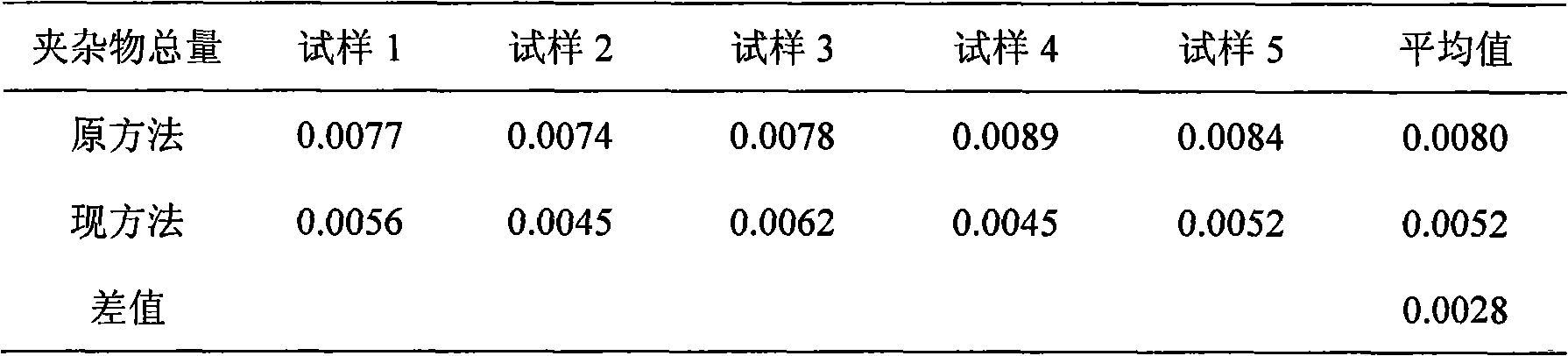

Examples

Embodiment Construction

[0011] The specific embodiment of the present invention is described further below:

[0012] 1. Steelmaking: A 100-ton converter is used, and the loading capacity is: 94.6 tons of molten iron and 12.4 tons of scrap steel. After the composition and temperature of the molten steel meet the requirements, the slag is blocked and tapped.

[0013] 2. Refining: use LF furnace refining and VD refining device to refine and degas the molten steel, so that the temperature and composition of the molten steel meet the requirements of the continuous casting machine, during which the molten steel is blown with argon throughout;

[0014] 3. Continuous casting: Before injecting molten steel into the tundish through the long nozzle at the bottom of the molten steel tank, blow nitrogen into the tundish with a vent pipe (φ32mm) on the upper part of the tundish, and the nitrogen pressure is 0.4MPa; After being capped by nitrogen gas (about 2-3 minutes), open the nozzle at the bottom of the molten ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com