Method for anti-adhesion nitrogen increase in the process of producing vanadium nitride

A production process, vanadium nitride raw material technology, applied in the field of vanadium nitride alloy production, to achieve the effect of preventing sticking, improving apparent quality, and preventing sintering sticking problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

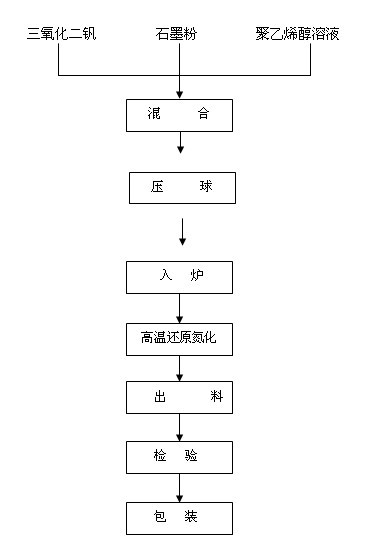

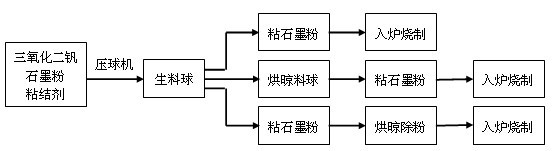

Method used

Image

Examples

Embodiment 1

[0022] Dry or dry the raw meal balls extruded by the ball briquetting machine, put them into the graphite powder and put them into the pusher kiln for firing. The thickness of the sticky graphite powder is about 0.01mm. Put the raw meal balls pretreated in this way into the furnace Firing, the vanadium nitride product with greatly improved bonding was obtained, and vanadium nitride containing 12.78% nitrogen was obtained. content increased by 1.02 percentage points.

Embodiment 2

[0024]Put the freshly extruded raw meal balls directly into the graphite powder, and the thickness of the sticky graphite powder is about 1mm. Put the raw meal balls pretreated in this way into the furnace and burn them to obtain unbonded vanadium nitride product, but at this time there is unreacted residual graphite powder on the surface of the product, which can be effectively removed by compressed air blowing, etc., and vanadium nitride with a nitrogen content of 13.96% is obtained, which is the same as that of the untreated product of the same batch of raw pellets with a nitrogen content of 11.76%. % of vanadium nitride, the nitrogen content increased by 2.2 percentage points.

Embodiment 3

[0026] Put the newly extruded raw material balls from the briquetting machine directly into the graphite powder. At this time, the thickness of the sticky graphite powder is about 1mm. Dry or dry the sticky pellets and put them in the furnace with a fork, which can be used Part of the graphite powder fell off from the surface of the raw meal balls, and the raw meal balls pretreated in this way were fired in the furnace. At this time, the product obtained had only a small amount of bonding, and the vanadium nitride with a nitrogen content of 14.54% was obtained, which was the same as that of the same batch of raw meal balls. Compared with the vanadium nitride containing 11.76% nitrogen, the nitrogen content increased by 2.78 percentage points.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com