Superheated steam sterilization equipment and superheated steam sterilization method

A technology of superheated steam and sterilization equipment, which is applied in the direction of heating, heating preservation of fruits/vegetables, food preservation, etc., which can solve problems affecting production operation and pipeline blockage, and achieve the effect of short high-temperature sterilization time and reduced processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

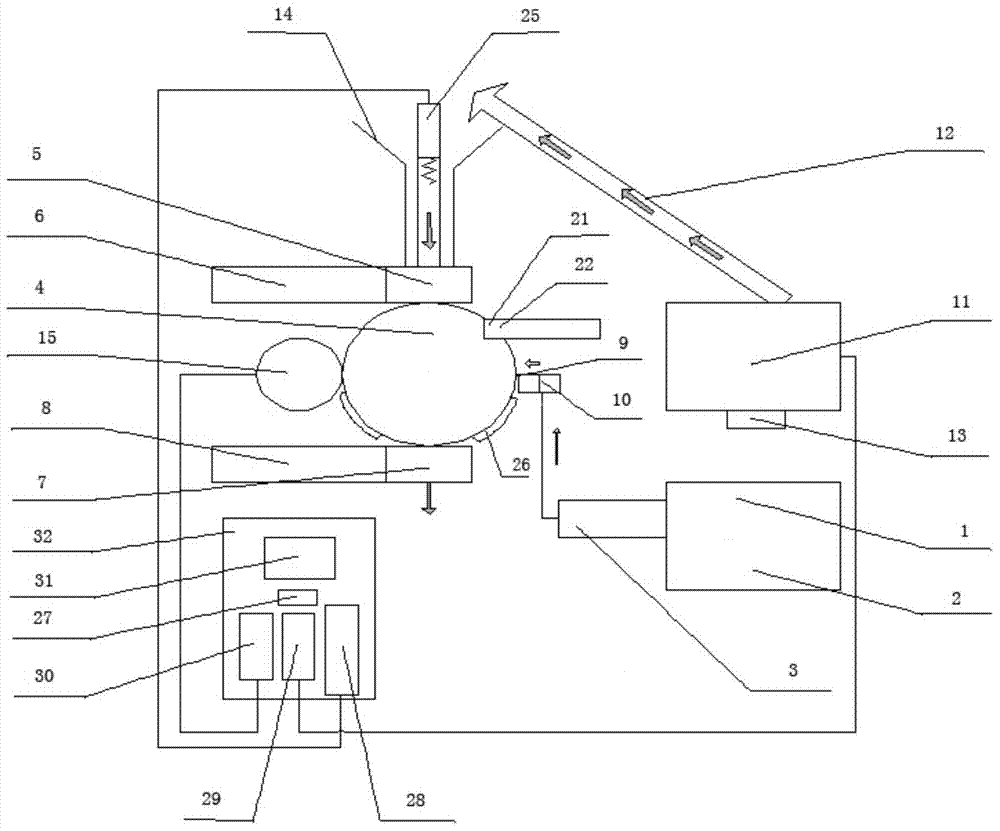

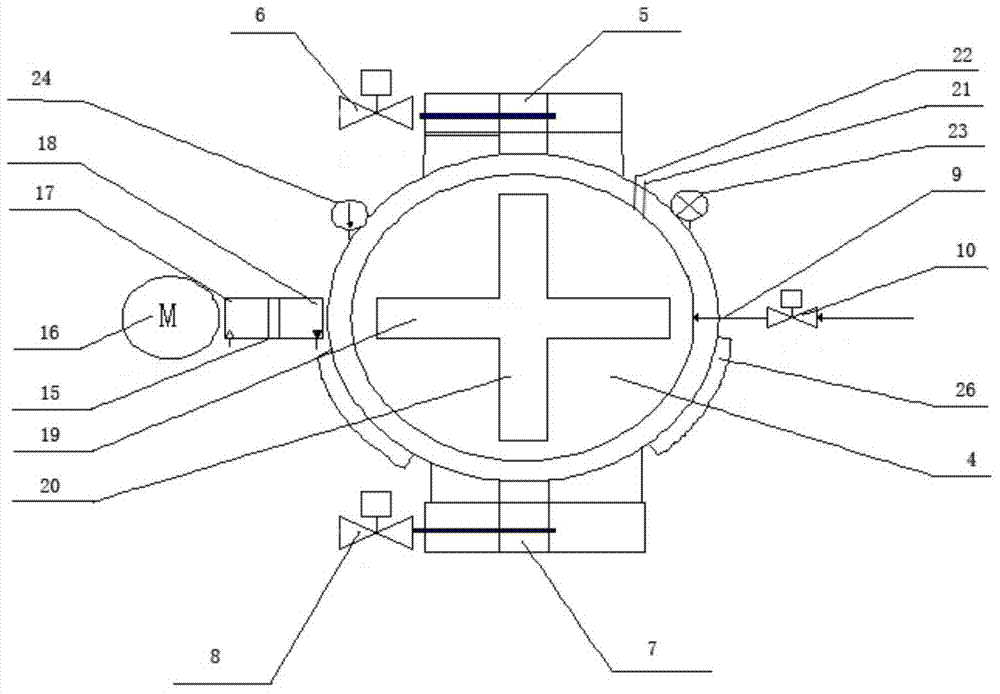

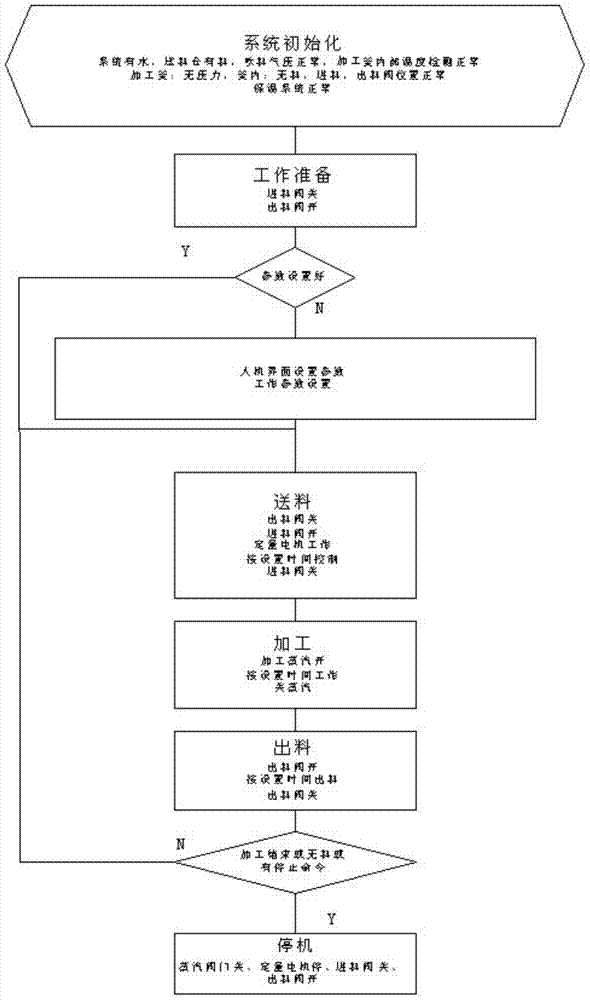

[0026] like Figure 1 to Figure 2 As shown, the superheated steam sterilization equipment includes a processing tank 4 that can accommodate materials to be sterilized and a superheated steam generator 1 that supplies superheated steam to the processing tank 4. A steam generator 2 and a steam heater 3 that heats saturated steam into superheated steam, and the superheated steam directly heats and sterilizes the materials in the processing kettle 4 . The top of this processing kettle 4 is provided with a feed inlet 5, and this feed inlet 5 is provided with a feed valve 6, and the bottom of this processing kettle 4 is provided with a discharge outlet 7, and this discharge outlet 7 is provided with A discharge valve 8, a superheated steam inlet 9 is arranged in the middle of the processing kettle 4, and a steam valve 10 is arranged on the superheated steam inlet 9. The feed valve 6, discharge valve 8, and steam valve 10 are all pneumatic valves, and the inlet of the steam valve 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com