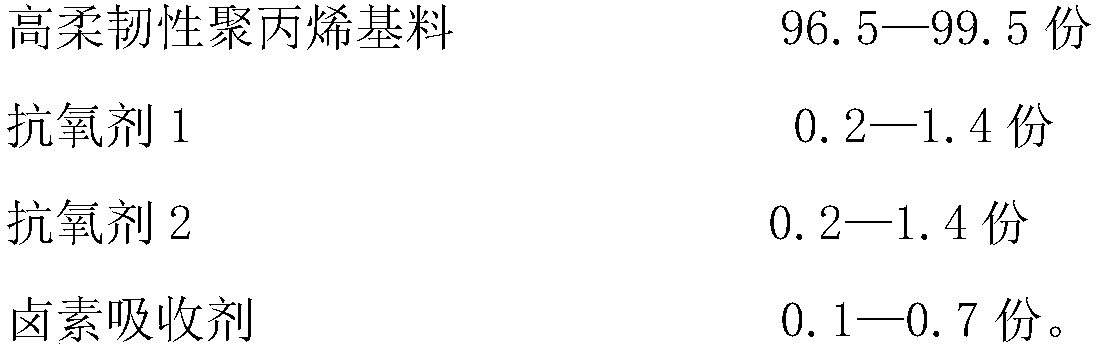

High-toughness polypropylene resin and production method thereof

A polypropylene resin and flexibility technology, which is applied in the production field of the high-flexibility polypropylene resin, can solve the problems of leakage from the outside of the package, poor sealing, poor transparency, etc., and achieves low residual activity, low density, and staying short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

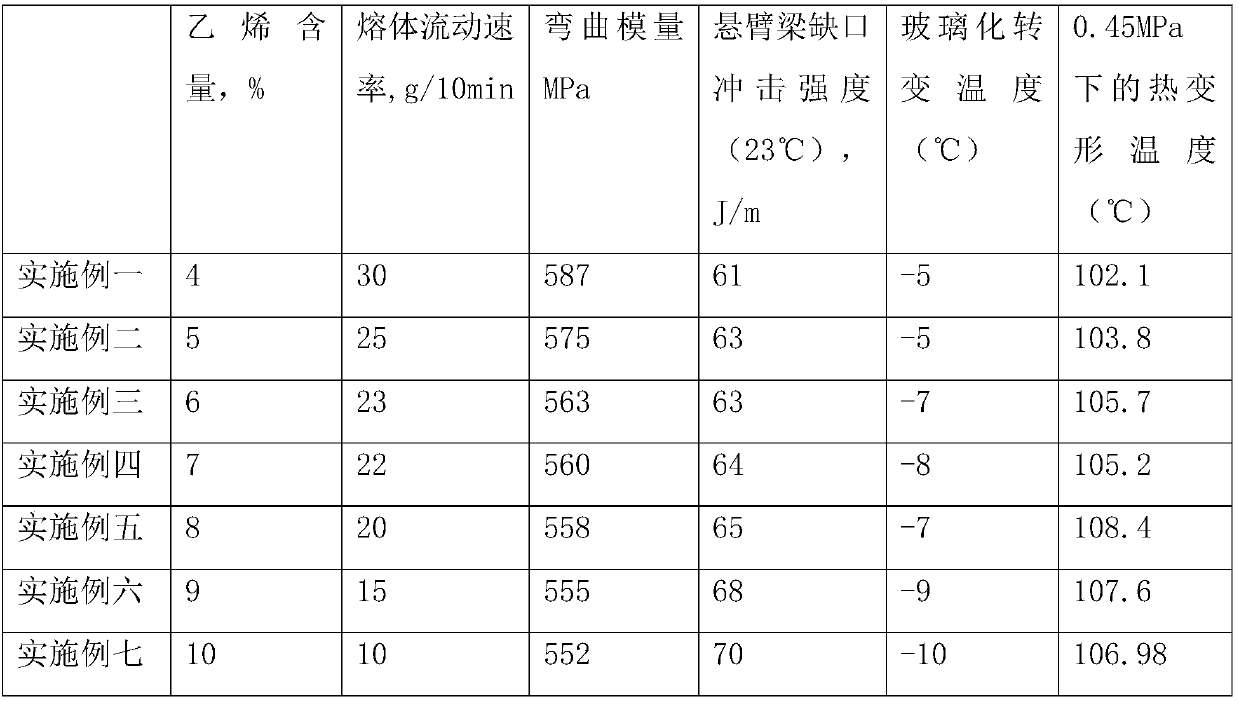

Examples

Embodiment 1

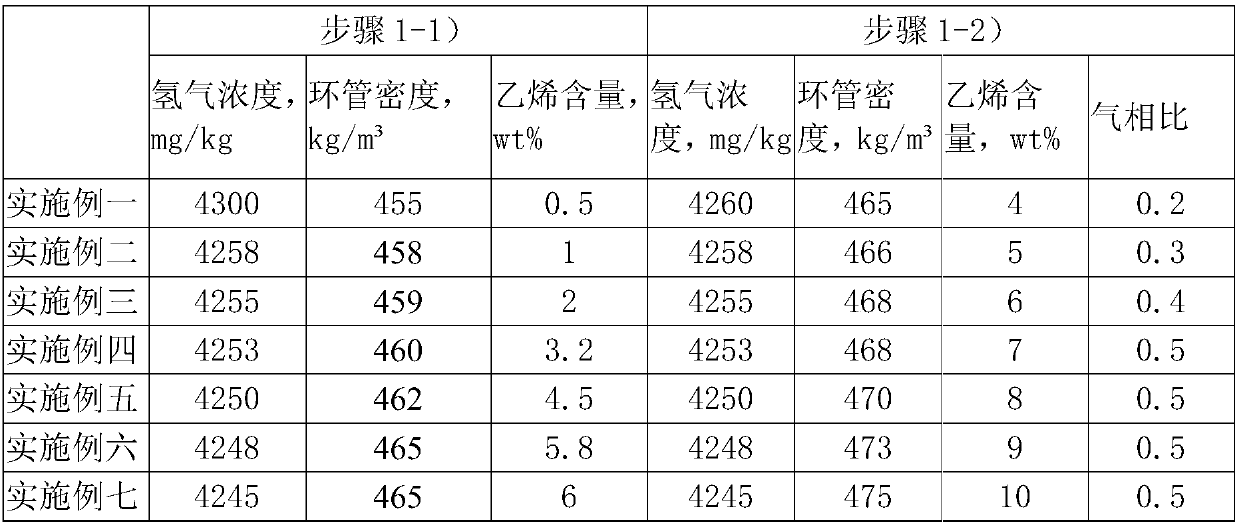

[0039] The steps of the production method of the highly flexible polypropylene resin of Example 1 are as follows:

[0040] Step 1) In the Spheripol process, a two-step composite method is used to produce a highly flexible polypropylene base material, specifically:

[0041] Step 1-1) In the first loop reactor, using propylene, ethylene and hydrogen as raw materials, add catalyst DQC-602, co-catalyst TEAL2 and electron donor DONOR-C2, and control the hydrogen concentration to 4300mg / kg , Ring tube density 455kg / m 3 , Ethylene content 0.5wt%, production of random copolymer polypropylene;

[0042] Step 1-2) Step 1-2: In the second loop reactor, the propylene homopolymer and ethylene monomer in the polypropylene product of the random copolymerization of the first step undergo a gas phase copolymerization reaction, and the hydrogen concentration is controlled to 4260 mg / kg. Tube density 465kg / m 3 , The ethylene content is 4wt%, and the air ratio is 0.2 to obtain polypropylene powder, whic...

Embodiment 2

[0045] The steps of the production method of the highly flexible polypropylene resin of the second embodiment are as follows:

[0046] Step 1) In the Spheripol process, a two-step composite method is used to produce a highly flexible polypropylene base material, specifically:

[0047] Step 1-1) In the first loop reactor, using propylene, ethylene and hydrogen as raw materials, add catalyst DQC-602, co-catalyst TEAL and electron donor DONOR-C, and control the hydrogen concentration to 4258mg / kg , Ring tube density 458kg / m 3 , Ethylene content of 1.0wt%, production of random copolymer polypropylene;

[0048] Step 1-2) In the second loop reactor, the propylene homopolymer and ethylene monomer in the polypropylene product of the random copolymerization of the first step are subjected to gas phase copolymerization, and the hydrogen concentration is controlled to 4258 mg / kg. Tube density 466kg / m 3 , The ethylene content is 5wt%, and the air ratio is 0.3 to obtain polypropylene powder, whi...

Embodiment 3

[0051] The steps of the production method of the highly flexible polypropylene resin of the third embodiment are as follows:

[0052] Step 1) In the Spheripol process, a two-step composite method is used to produce a highly flexible polypropylene base material, specifically:

[0053] Step 1-1) In the first loop reactor, propylene, ethylene, and hydrogen are used as raw materials, and the catalyst DQC-602, the co-catalyst TEAL and the electron donor DONOR-C are added to control the hydrogen concentration to 4255mg / kg , The density of the ring tube is 459kg / m 3 , Ethylene content 2.0wt%, production of random copolymer polypropylene;

[0054] Step 1-2) In the second step, in the second loop reactor, the propylene homopolymer and ethylene monomer in the polypropylene product of the random copolymerization in the first step are subjected to gas phase copolymerization, and the hydrogen concentration is controlled to 4255mg / kg. Tube density 468kg / m 3 , The ethylene content is 6wt%, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com