Cold patch asphalt mixture prepared from clay minerals and preparation method of cold patch asphalt mixture

A technology for cold patching asphalt and clay minerals, which is applied in the field of preparing cold patching asphalt mixtures, can solve the problems of inoperable construction, complex preparation process, short service life, etc., and achieves the effects of reducing road maintenance costs, simple procedures and low prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1-2

[0037] The preparation method of example 1-2 cold patch asphalt mixture is:

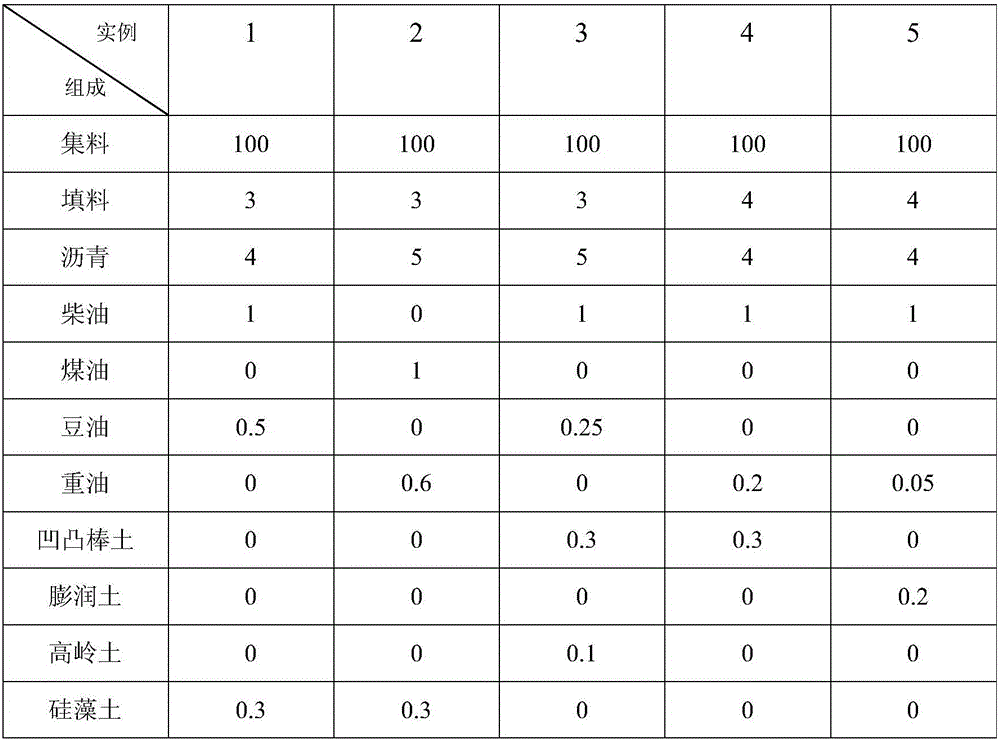

[0038] 1) prepare raw materials by the mass ratio shown in Table 1;

[0039] 2) Mix the aggregate and filler evenly;

[0040] 3) Heat the asphalt to 125°C, first add clay mineral materials, stir to make it completely dissolve in the asphalt, add diluent when the temperature drops to 110°C, and stir thoroughly to make cold patch asphalt;

[0041] 4) Mix the cold-patch asphalt with a temperature of 80°C with certain graded aggregates and fillers, and mix them with a mixer to make a cold-patch asphalt mixture.

example 3-5

[0042] The preparation method of example 3-5 cold patch asphalt mixture is:

[0043] 1) prepare raw materials by the mass ratio shown in Table 1;

[0044] 2) Mix the aggregate and filler evenly;

[0045] 3) Heat the asphalt to 140°C, first add clay mineral material, stir to make it completely dissolve in the asphalt, add diluent when the temperature drops to 90°C, stir fully, and make cold patch asphalt;

[0046] 4) Mix the cold-patch asphalt at a temperature of 70°C with certain graded aggregates and fillers, and mix them with a mixer to make a cold-patch asphalt mixture.

[0047] The performance of the cold patch asphalt mixture prepared by example 1-5 is as follows:

[0048] (1) Low-temperature workability: Keep the temperature in the refrigerator at -10°C for 24 hours, take it out and place it at room temperature for two hours. After the temperature of the mixture reaches room temperature, it is easier to mix with a spade, and the mixture does not agglomerate. Good work...

PUM

| Property | Measurement | Unit |

|---|---|---|

| residual stability | aaaaa | aaaaa |

| freeze-thaw splitting strength ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com