System and method for preparing hydrogen peroxide through anthraquinone method under supergravity condition

A technology of hydrogen peroxide and anthraquinone method, applied in chemical instruments and methods, peroxide/peroxyhydrate/peroxyacid/superoxide/ozonide, inorganic chemistry, etc., can solve the problem of low catalyst efficiency, Small investment, large equipment volume and other problems, to achieve the effect of fast gas-liquid renewal speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

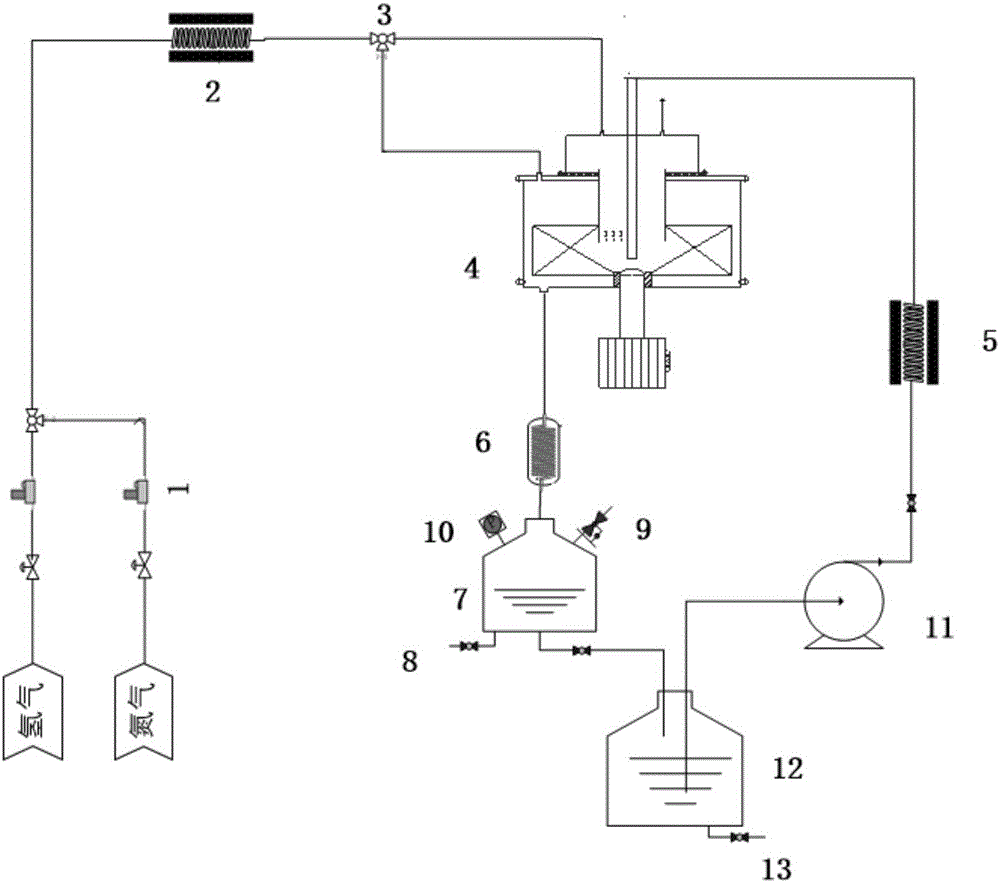

[0083] A system for preparing hydrogen peroxide by anthraquinone method, said system comprising a high-gravity rotating packed bed 4, a gas delivery device, a liquid delivery device, a first preheating furnace 2, a second preheating furnace 5, a condenser 6, Product storage tank and liquid inlet pipe;

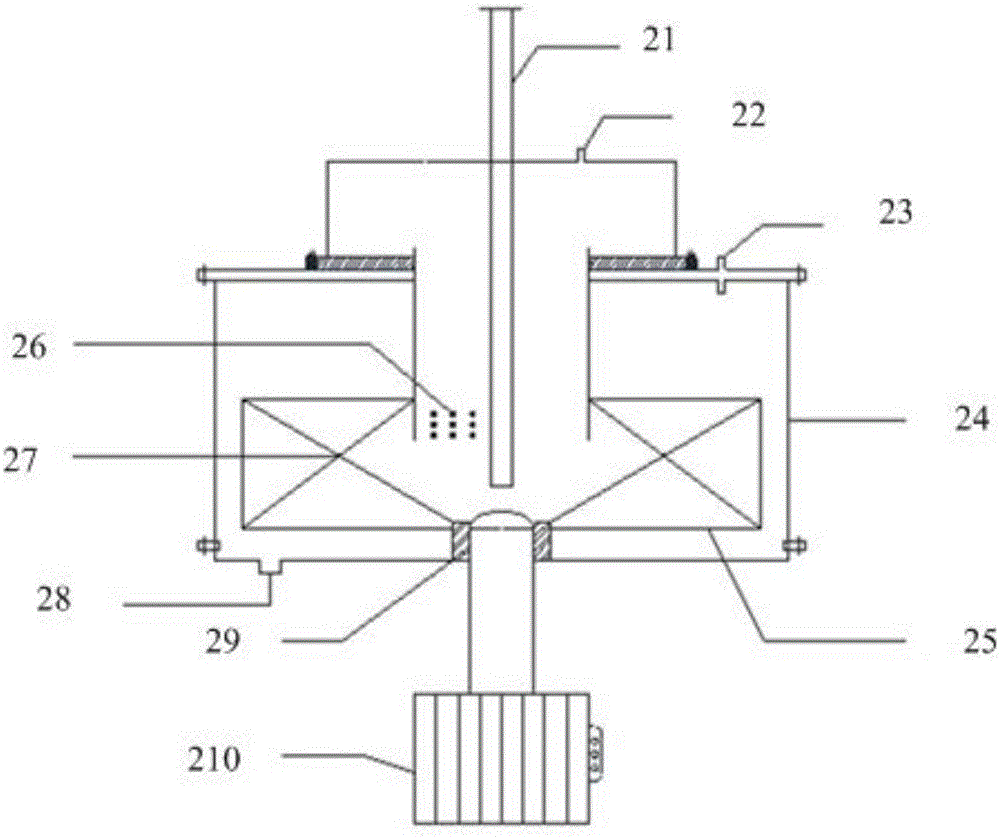

[0084] The high-gravity rotating packed bed 4 includes a shell, a reactor and a rotating device, the reactor is located in the shell, the wall of the reactor is filled with a hydrogenation catalyst, and the wall of the reactor is provided with through holes, and the reactor passes through the The through hole communicates with the shell; the rotating device is connected with the reactor to drive the reactor to rotate;

[0085] The through hole is circular and has a plurality of; the through hole is provided with a wire mesh; the interval between adjacent through holes is 1mm; the reactor is a hollow cylinder; the wall of the cylinder The thickness is 21mm; the radius of the cy...

Embodiment 2

[0096] A circulation system for the preparation of hydrogen peroxide by anthraquinone method, such as figure 1 shown. The system is the same as the system described in Embodiment 1 except that the product storage tank is also connected to the working fluid storage tank 12 .

[0097] Utilize the method for preparing hydrogen peroxide of above-mentioned system to comprise the steps:

[0098] (1) Fill the wall of the high-gravity rotating packed bed reactor with catalyst, heat the high-gravity rotating packed bed to 50-80°C, pass in hydrogen for reduction and activation for 1-24 hours, and exhaust it with nitrogen; make the high-gravity The rotating packed bed rotates at a speed of 0-3000r / min;

[0099](2) The working liquid with a temperature of 55-75°C is sprayed from the liquid inlet pipe onto the inner wall of the rotating reactor, and the hydrogen gas with a temperature of 55-75°C flows through the catalyst in the reactor wall in the axial phase or radial direction, On th...

Embodiment 3

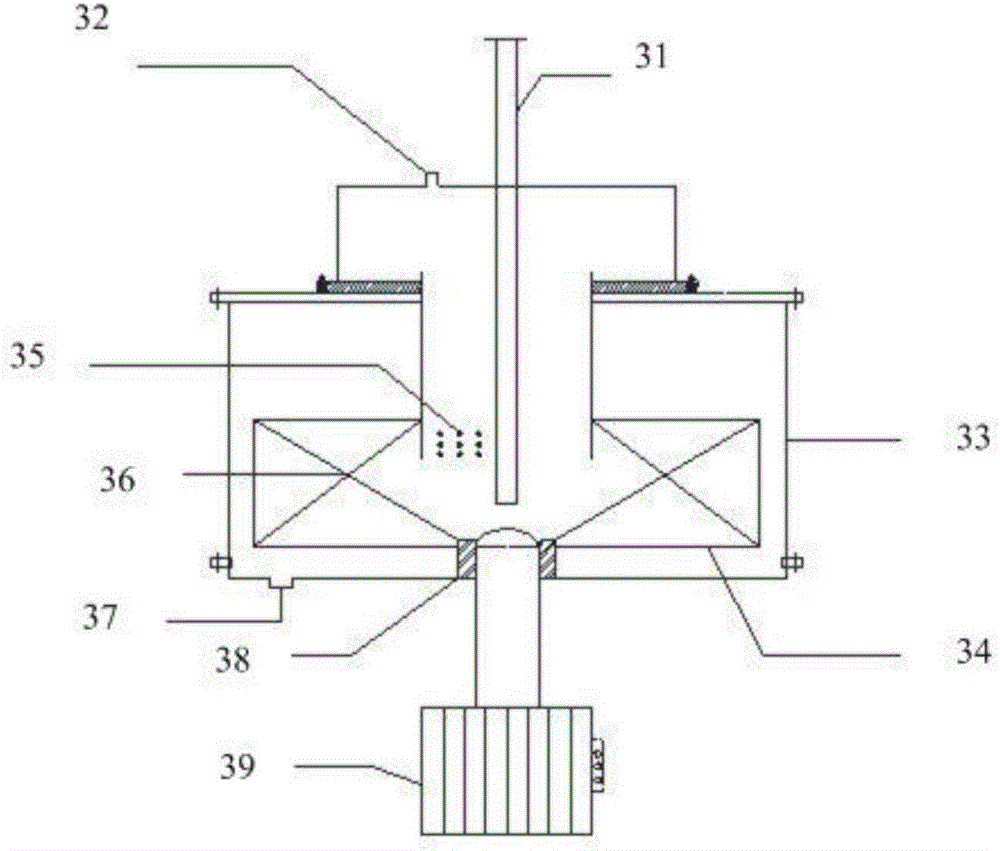

[0103] A kind of multistage reaction system that is used for anthraquinone method to prepare hydrogen peroxide, described system comprises three high-gravity rotating packed beds 4 (the first high-gravity rotating packed bed, the second high-gravity rotating packed bed and the third high-gravity rotating packed bed Rotating packed bed), gas delivery device, liquid delivery device, first preheating furnace 2, second preheating furnace 5, condenser 6, product storage tank and liquid inlet pipe;

[0104] Each high-gravity rotating packed bed 4 includes a shell, a reactor and a rotating device, the reactor is located in the shell, the wall of the reactor is filled with a hydrogenation catalyst, and the wall of the reactor is provided with through holes, and the reactor passes through The through hole is communicated with the shell; the rotating device is connected with the reactor to drive the reactor to rotate;

[0105] The through hole is circular and has a plurality of; the thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com