Method for machining extension drill

A processing method and drill technology, applied in the field of mechanical processing, can solve problems such as the inability to meet the processing requirements of extended drill bits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

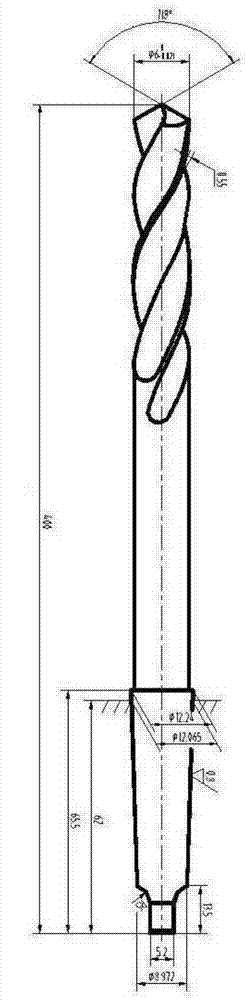

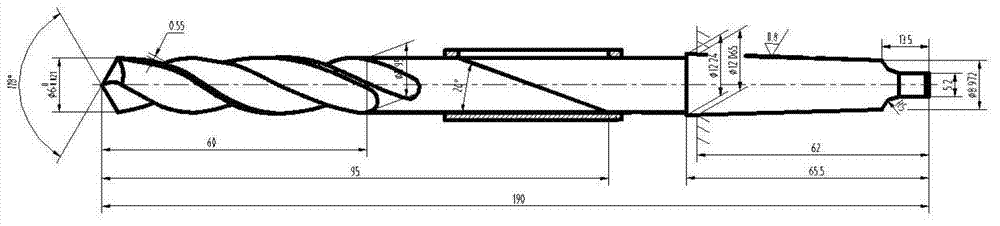

[0022] The specific implementation method of the present invention is: Step 1: Grinding standard straight shank twist drill bit 60 ° anti-top; 60° anti-top to provide an accurate positioning reference for subsequent sequences;

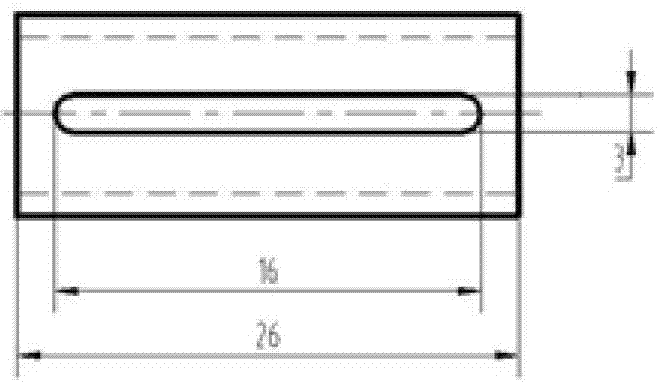

[0023] Step 2: Turning the welding sleeve; the welding sleeve is an auxiliary part when welding the standard straight shank twist drill and the tool holder to prevent the loss of the flux when it is heated and melted; the inner hole of the welding sleeve and the straight shank outer circle of the straight shank twist drill are 0.2 mm clearance fit to ensure welding precision requirements;

[0024] Step 3: Turning the tool bar; the outer circle of the left end tool bar is matched with the inner hole of the welding sleeve with a clearance of 0.2mm to ensure the welding accuracy requirements; the outer circle of the tool bar taper handle has a grinding allowance of 0.6-0.7mm, and the right end of the tool bar is drilled in the center hole; in order to re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com