Bent axle coaxiality detecting device and detecting technology of high-power multi-cylinder internal combustion engine

A multi-cylinder internal combustion engine and detection device technology, applied in the direction of mechanical measuring devices, measuring devices, mechanical devices, etc., can solve the problem of not being able to obtain the coaxiality of the crankshaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in conjunction with accompanying drawing and specific embodiment:

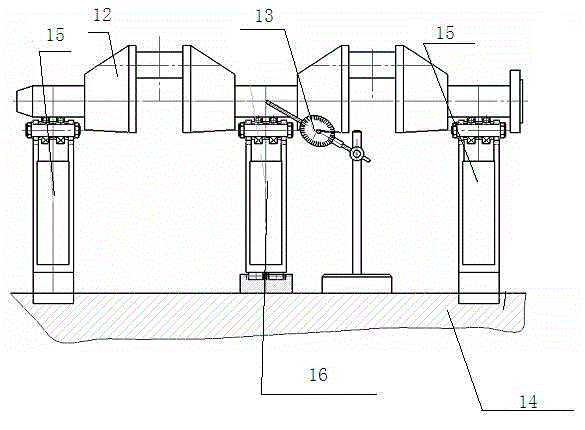

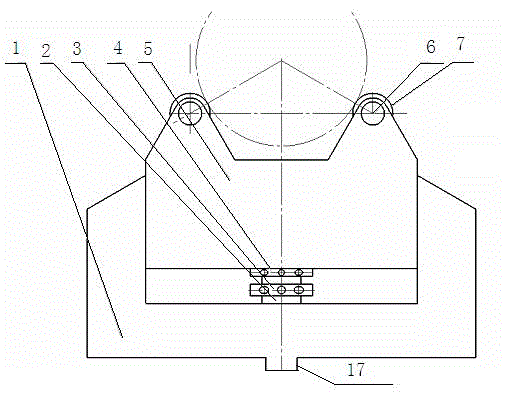

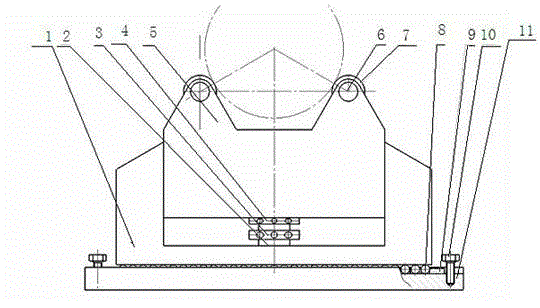

[0018] like figure 1 As shown, a crankshaft coaxiality detection device for a high-power multi-cylinder internal combustion engine, the crankshaft coaxiality detection device includes three detection supports, a dial indicator 13 and a detection platform 6; the three detection supports are respectively Set at the main journal at the free end of the crankshaft 12, the main journal at the output end of the crankshaft 12 and the main journal at the middle of the crankshaft 12; combined figure 2 , image 3, the structure of the fixed detection support in the prior art is the same, this support can not move in the direction perpendicular to the axis of the crankshaft because of the positioning of the rectangular groove, so it is called a fixed support; it includes a support seat 1, a support body 5 and a lead screw nut mechanism for lifting the support body 5 relative to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com