Argon shielding device for titanium material welding and usage method of device

A technology of argon gas shielding and gas shielding, which is applied to devices, welding equipment, welding accessories, etc. for providing/removing shielding gas, which can solve problems such as affecting the quality of welds, achieve smooth argon gas flow, save manufacturing costs, and low costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail with reference to the accompanying drawings.

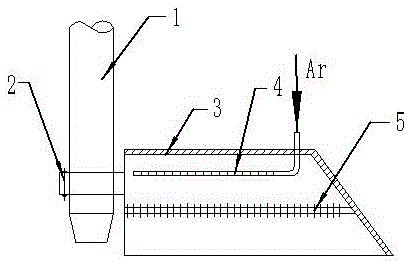

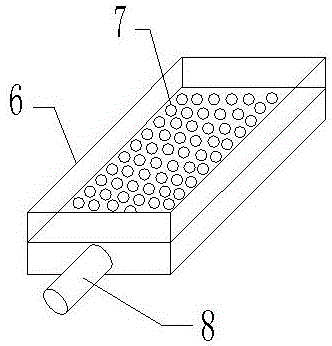

[0013] The structure of the present invention includes two parts: an upper gas protection cover and a lower gas protection tank; the structure of the upper gas protection cover is as follows: figure 1 Shown are: welding torch 1, throat clamp 2, tail drag cover 3, ventilation pipe 4, perforated plate 5; throat clamp 2 can clamp the argon arc welding torch, tail drag cover 3 is connected with throat clamp 2, and ventilation tube 4 There are some small holes at the bottom, located above the perforated plate 5; the structure of the lower gas protection groove is as follows: figure 2 Shown are: a steel plate groove 6, a perforated plate 7, and an air intake pipe 8; wherein the perforated plate 7 is located in the middle of the steel plate groove 6, and the air intake pipe 8 enters the steel plate groove 6 from below the perforated plate 7. The above components are all connected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com