Glass curtain wall

A glass curtain wall and glass panel technology, which is applied in the direction of walls, building components, buildings, etc., can solve the problems of poor permeability and overall visual effect, poor redundancy of single-rib curtain wall structure, and increased cost of curtain wall manufacturing. The effect of reducing construction labor intensity, ensuring process and product quality, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

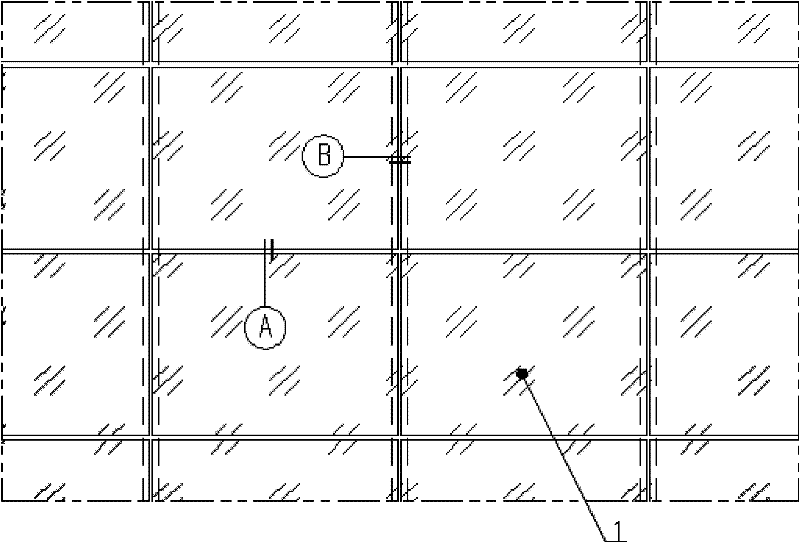

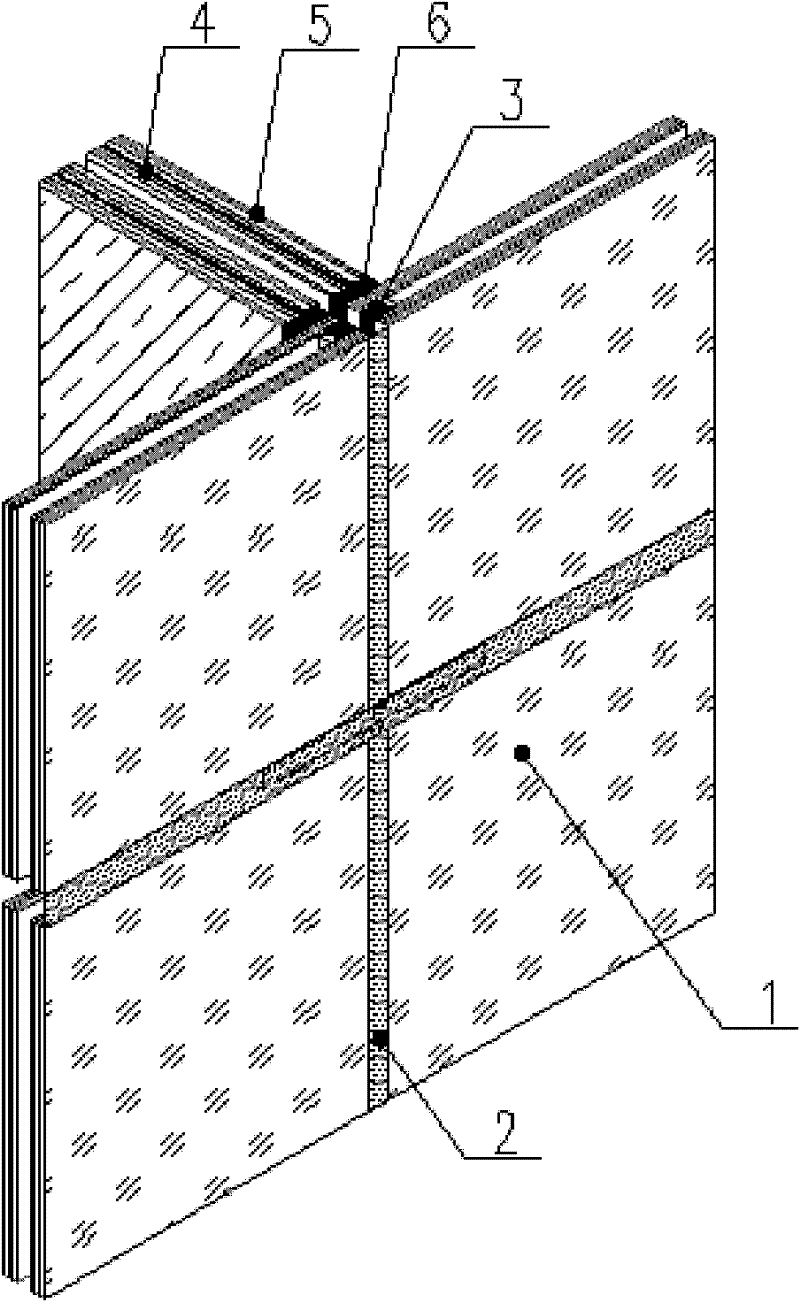

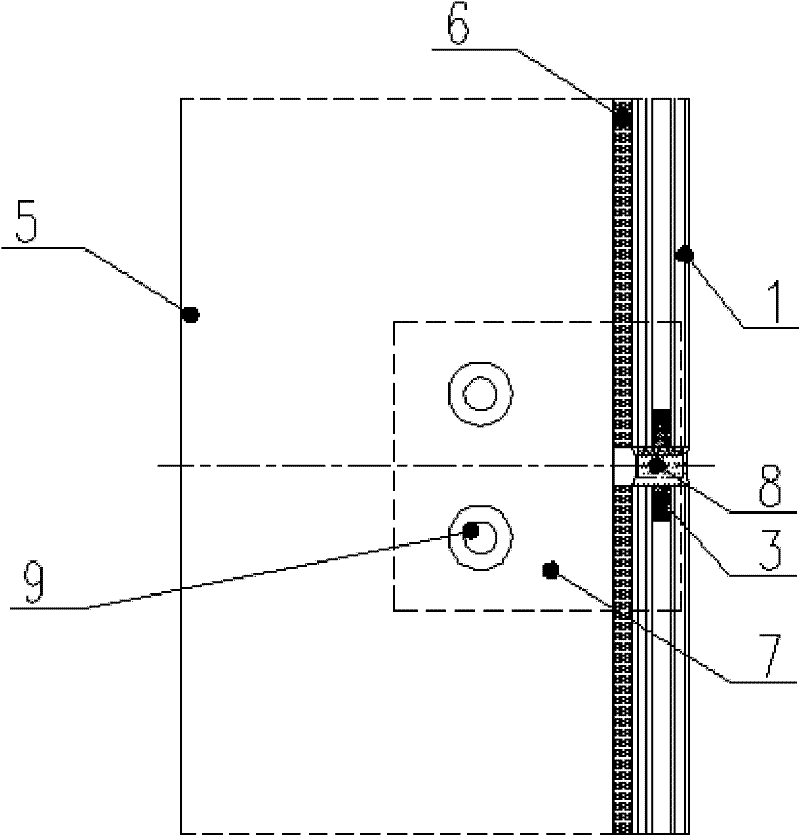

[0021] Such as figure 1 As shown, the glass curtain wall of this embodiment is an all-glass curtain wall, and each glass panel 1 is made of double-layer glass, with a vacuum in the middle and sealed with hollow glue 3 around it. At the rear of the glass panel is a fixed support frame. combine Figure 2-6 , the fixed support frame includes two ribs, the span of the two ribs is the entire interlayer height, and each rib is bonded into one body by PVB glue 4 in the middle of two glass sheets 5 respectively. There is a vertical supporting plate 7 between the two ribs, and the front edge of the vertical supporting plate protrudes from between the two ribs, and the extension length is slightly smaller than the thickness of the glass panel. The vertical supporting plate and the two ribs are formed by Compatibility anti-shear glue 10 is bonded into one body, and is fastened by two upper and lower bolts 9 through the openings on the vertical supporting plate and the floor plate, for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com