Functional lining body paper for cigarettes and preparation method of functional lining body paper

A functional, lining paper technology, which is applied in papermaking, packaging paper, paper coating, etc., can solve the problems of slow speed of compound machines, failure to achieve high barrier function, and no requirement for dimensional stability, and achieve high barrier moisture retention Wetting, low water vapor transmission rate and water absorption, high wet strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

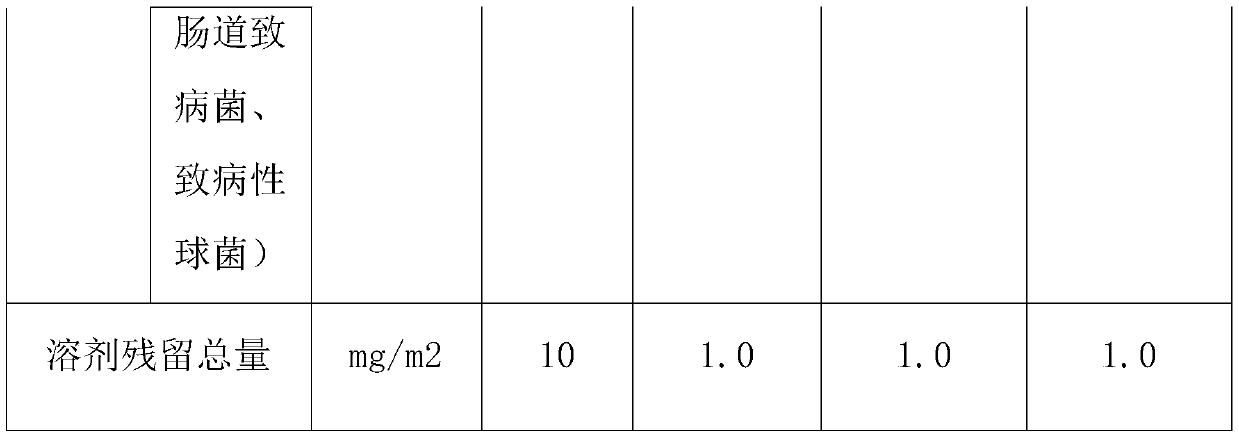

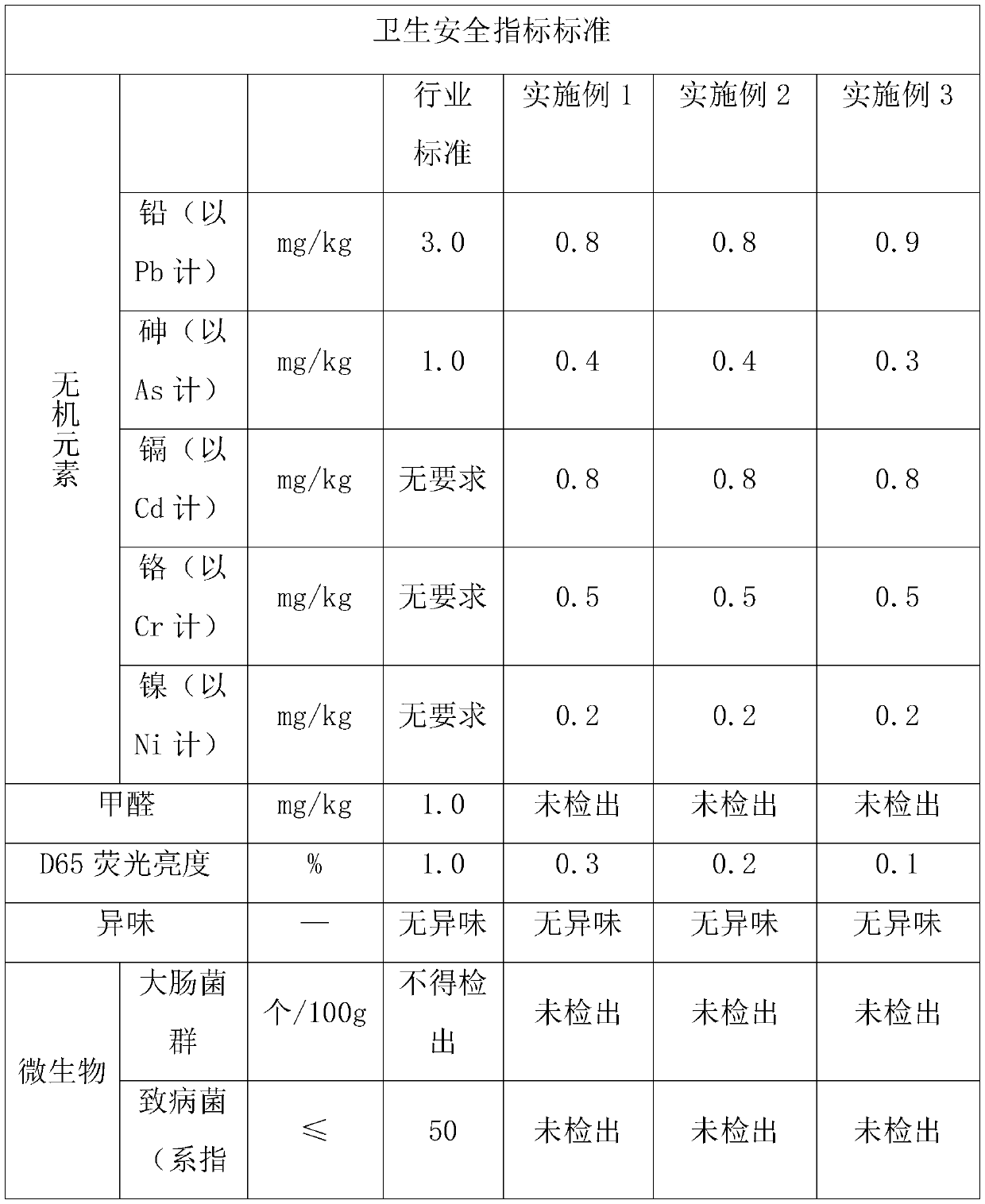

Embodiment 1

[0023] This embodiment provides a functional cigarette inner liner base paper, the base paper has a double-layer structure, one layer is the base layer of the inner liner base paper, and the other layer is a functional coating layer. The functional coating comprises: 16 parts of alkane wax compound emulsion, 25 parts of clay, 14 parts of diatomaceous earth, 13 parts of titanium dioxide, 10 parts of china clay, 10 parts of water-based polyvinyl alcohol, 12 parts by weight according to the composition of the functional coating. part acrylic resin copolymer.

[0024] The preparation method of the above-mentioned functional tobacco inner liner base paper includes: beating the softwood pulp and the hardwood pulp respectively, and the control parameters are: the beating degree of the softwood pulp is 50~54 0 SR, hardwood pulp percussion degree 55~59 0 SR, after beating, softwood pulp and hardwood pulp are mixed according to the mass percentage of 25% and 75%, and then epichlorohydr...

Embodiment 2

[0026] This embodiment provides a functional cigarette inner liner base paper, the base paper has a double-layer structure, one layer is the base layer of the inner liner base paper, and the other layer is a functional coating layer. The functional coating comprises: 17 parts of water-based polyurethane dispersion, 23 parts of pottery clay, 17 parts of diatomaceous earth, 15 parts of titanium dioxide, 8 parts of china clay, 12 parts of water-based polyvinyl alcohol, 8 parts of Acrylic resin copolymer.

[0027] The preparation method of the above-mentioned functional tobacco inner liner base paper includes: beating the softwood pulp and the hardwood pulp respectively, and the control parameters are: the beating degree of the softwood pulp is 50~54 0 SR, hardwood pulp percussion degree 55~59 0 SR, after beating, softwood pulp and hardwood pulp are mixed according to the mass percentage of 40% and 60%, and then epichlorohydrin resin, alkyl ketene dimer, 1-16 alcohol, polyacrylam...

Embodiment 3

[0029] This embodiment provides a functional cigarette inner liner base paper, the base paper has a double-layer structure, one layer is the base layer of the inner liner base paper, and the other layer is a functional coating layer. The functional coating comprises: 14 parts of water-based polyvinyl alcohol, 24 parts of clay, 15 parts of diatomaceous earth, 14 parts of titanium dioxide, 11 parts of china clay, 11 parts of water-based polyvinyl alcohol, 11 parts of Acrylic resin copolymer.

[0030] The preparation method of the above-mentioned functional tobacco inner liner base paper includes: beating the softwood pulp and the hardwood pulp respectively, and the control parameters are: the beating degree of the softwood pulp is 35~39 0 SR, hardwood pulp percussion degree 40~44 0 SR, after beating, softwood pulp and hardwood pulp are mixed according to the mass percentage of 10% and 90%, and then epichlorohydrin resin, alkyl ketene dimer, 1-16 alcohol, polyacrylamide and cati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com