Integrated control system of cement clinker, waste heat power generation and steam turbine safety protection

A waste heat power generation, cement clinker technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of inconsistent human-machine interface, reduce labor intensity, reduce labor capacity, etc., to ensure process strategy and The effect of production management, reducing labor intensity and reducing labor quota

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

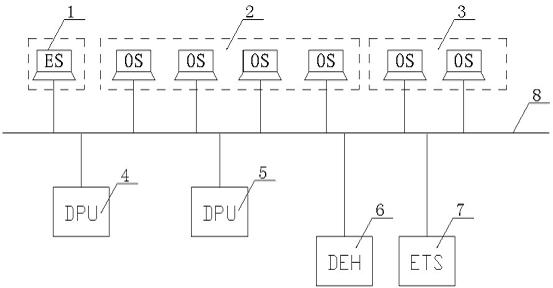

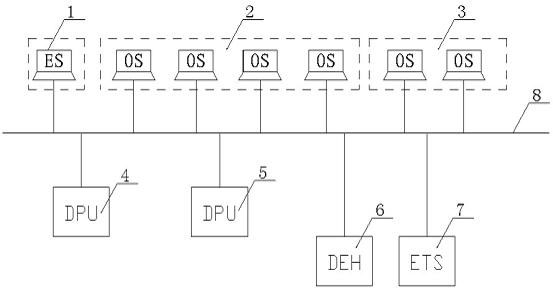

[0016] figure 1 Among them, the clinker cement "domain" (4) is composed of raw material control station, firing kiln tail control station, firing kiln head control station, and cement mill control station; waste heat power generation "domain" (5) is composed of boiler control station, steam Turbine generator control station, auxiliary equipment control station; steam turbine control and protection "domain" is composed of electro-hydraulic regulation system DEH (6) and emergency trip system ETS (7) control.

[0017] Field layer: the field intelligent bus device communicates with the CPU controller using the Profibus DP communication standard;

[0018] Control management layer: The industrial Ethernet TCP / IP protocol is used to realize the communication between the system controller and the operation station; each layer is independent and connected with each other, connected through a computer network system to achieve decentralized control of DCS and centralized management Pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com