Ultra-high pressure flow controller

A flow controller and ultra-high pressure technology, applied in valve details, safety valves, engine components, etc., can solve the problems of short life, poor performance, large natural decline, etc., to ensure service performance and process performance, small flow adjustment. Good characteristics and reasonable structure settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

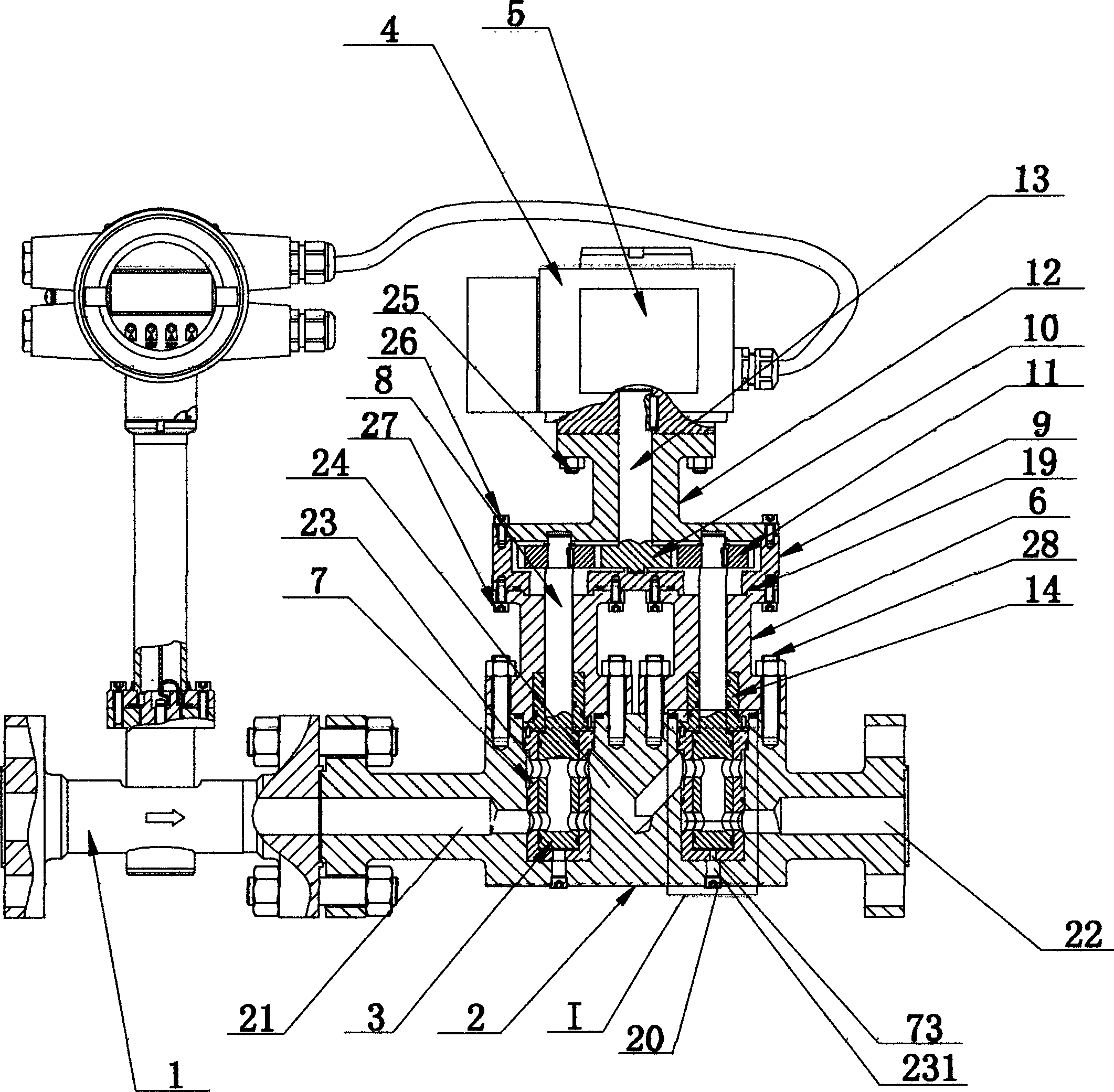

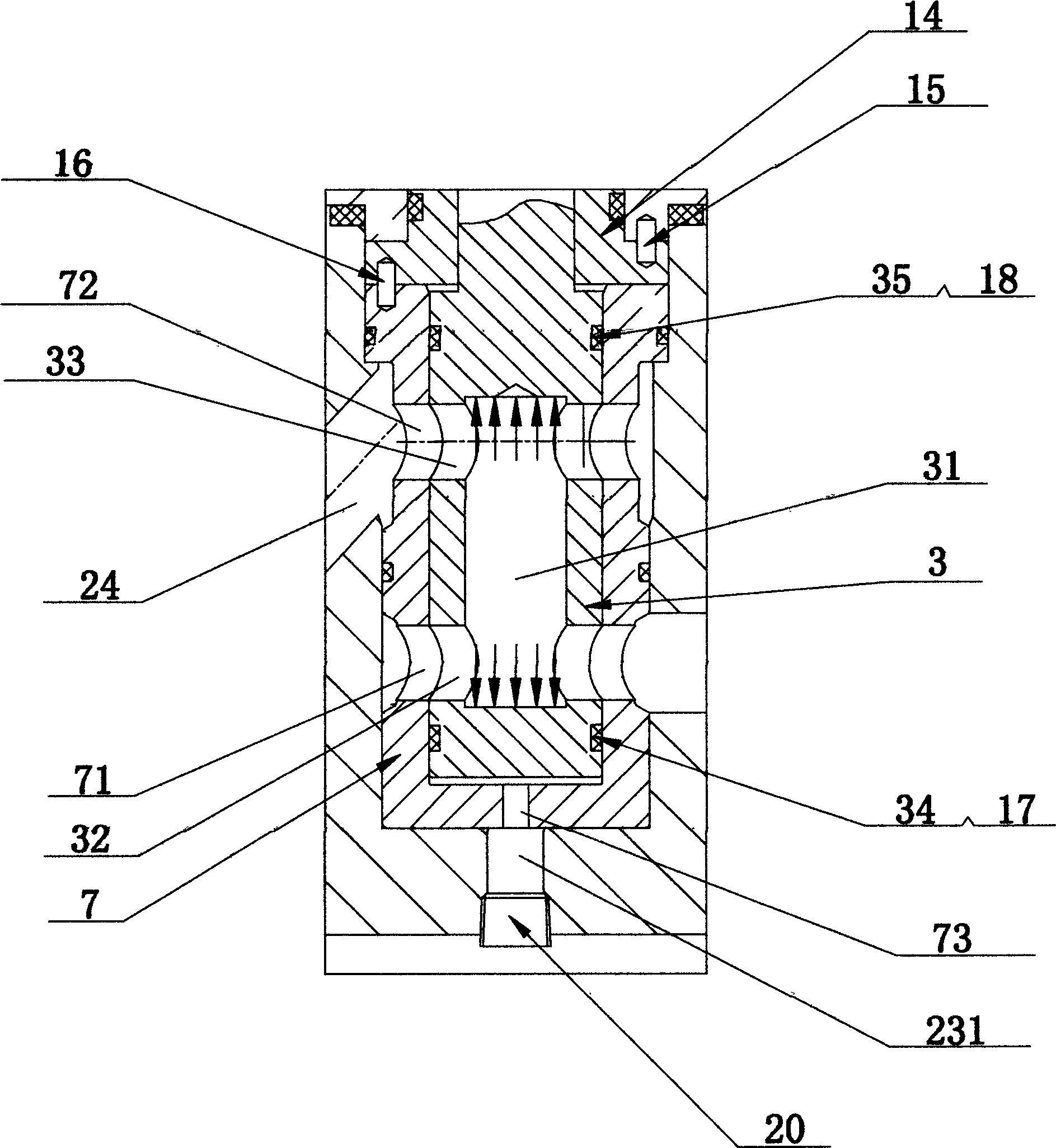

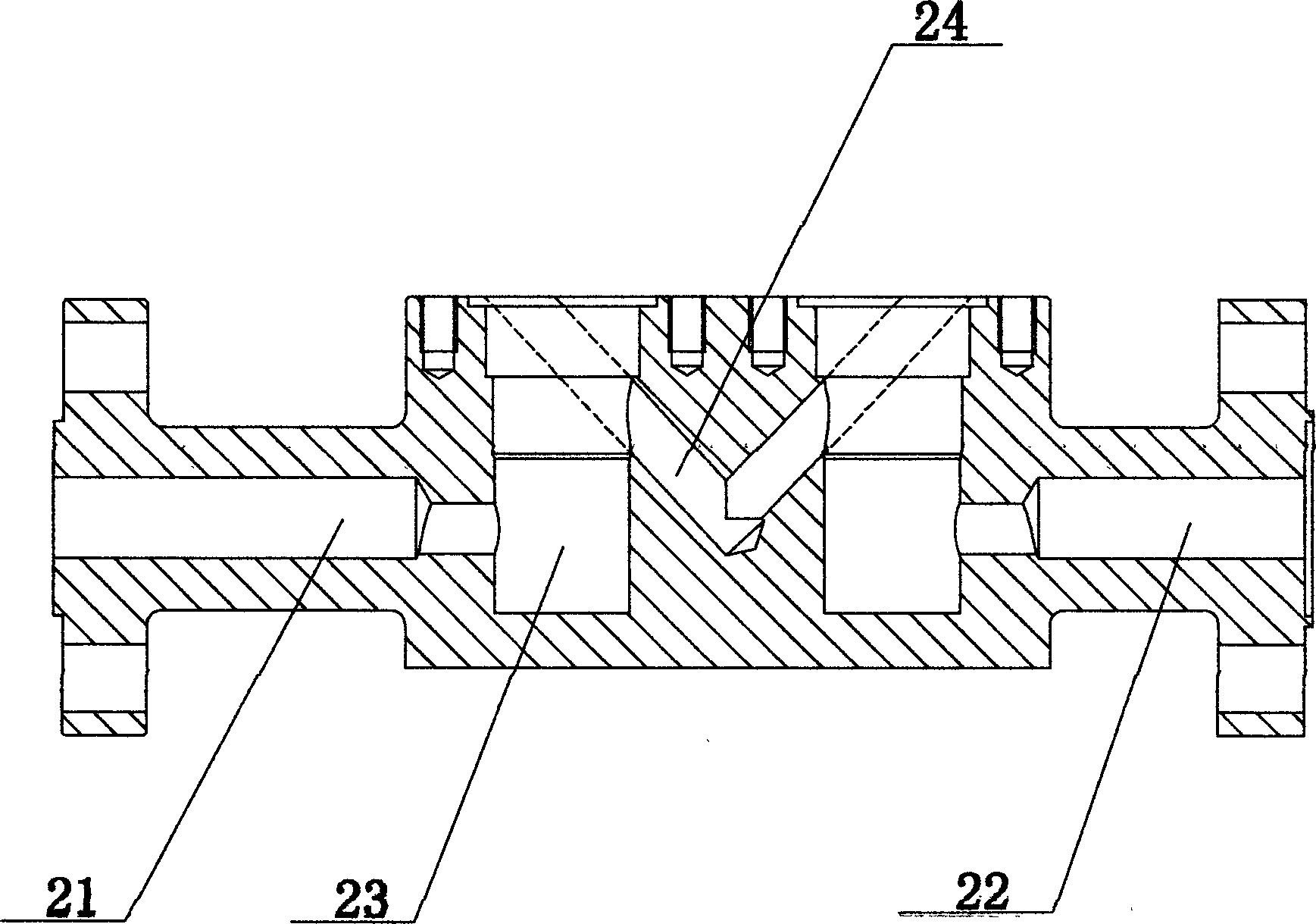

[0021] see figure 1 , figure 2 with image 3 , a UHV flow controller disclosed in the present invention, comprising a flow meter 1, a valve body 2, a valve core 3, an electric actuator 4, and a digital regulator 5, and the upper end of the valve body 2 is detachably provided with a valve cover 6 , the left and right ends of the valve body 2 are respectively provided with a fluid inlet 21 and a fluid outlet 22, and the middle part of the valve body 2 is vertically provided with two valve inner chambers 23, and a longitudinal valve inner chamber 23 is arranged between the two valve inner chambers A fluid channel 24 with a "V"-shaped cross-section, a sleeve 7 is installed in each valve inner cavity 23, and a valve core 3 is inserted into each sleeve 7, that is, a sleeve 7 is sleeved on each valve core 3 , the upper end of each spool 3 is integrally provided with a valve stem 8, the upper end of the valve cover 6 is detachably provided with a gear box 9, the gear box 9 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com