Rare earth mine tail water surface source pollution efficient percolation treatment system and process

A technology for a treatment system and a water distribution system is applied in the field of high-efficiency infiltration treatment systems for surface source pollution of rare earth mine tail water, which can solve the problems of large seasonal climate fluctuations, no biodegradability, and large water quality fluctuations, so as to reduce maintenance labor. Strength, perfect unit design, good effect of enrichment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the technical solutions in the specific embodiments of the present invention are clearly and completely described below to further illustrate the present invention. Obviously, the described specific implementation The form is only a part of embodiment of this invention, and it is not all form.

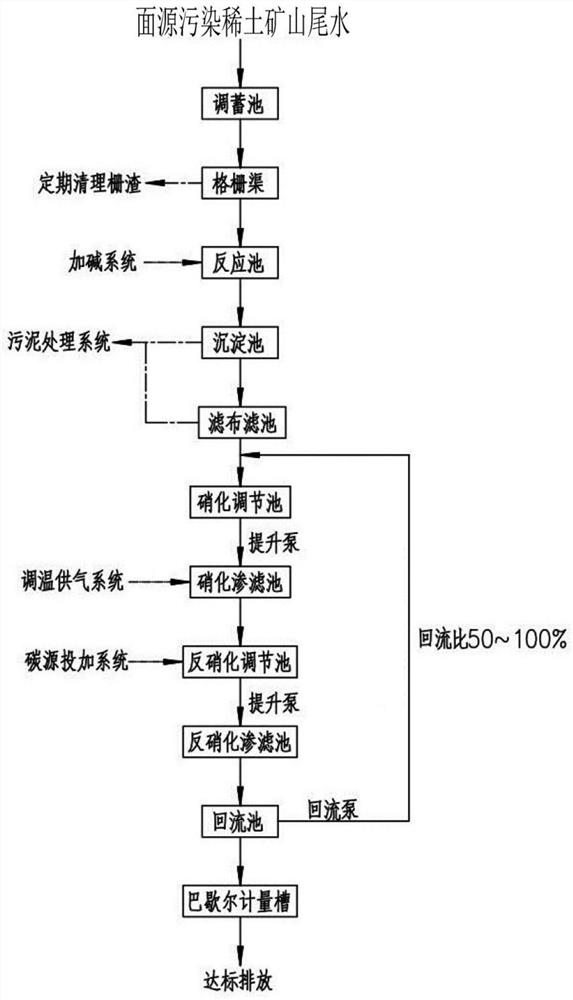

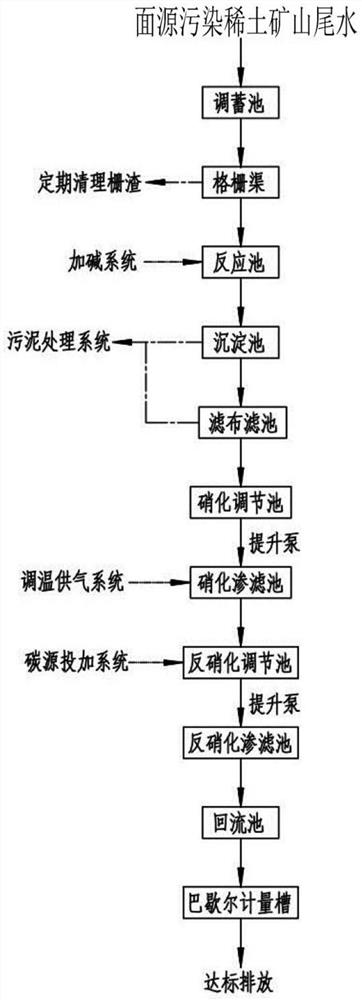

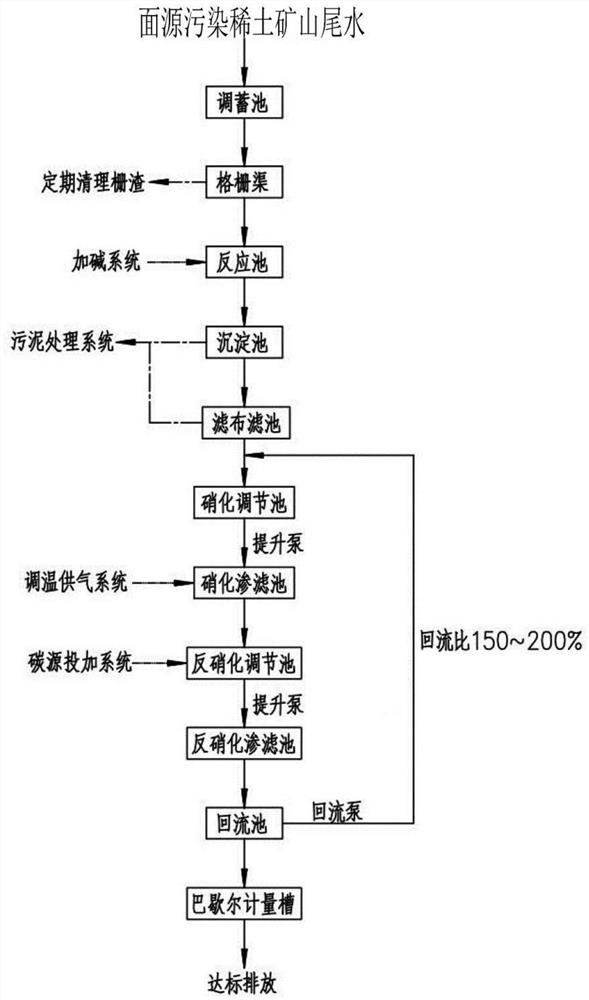

[0044] This specific embodiment is a high-efficiency percolation treatment system for surface source pollution of rare earth mine tail water, which consists of a watershed regulation and storage unit, a pretreatment unit, a percolation biochemical treatment unit, a backflow unit and an auxiliary unit.

[0045] The regulation and storage unit of the watershed includes storage tanks and sand control dams. The storage tanks are generally reservoirs or sedimentation sand ponds in the watershed. The optimal residence time of the storage tanks is greater than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com