Percolation biochemical treatment system for enhancing denitrification of percolation system

A biochemical treatment and percolation technology, applied in the field of percolation biochemical treatment systems, can solve the problems of unstable nitrification and denitrification, and achieve the effects of reducing energy consumption, improving oxygen utilization, and alleviating low biochemical temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

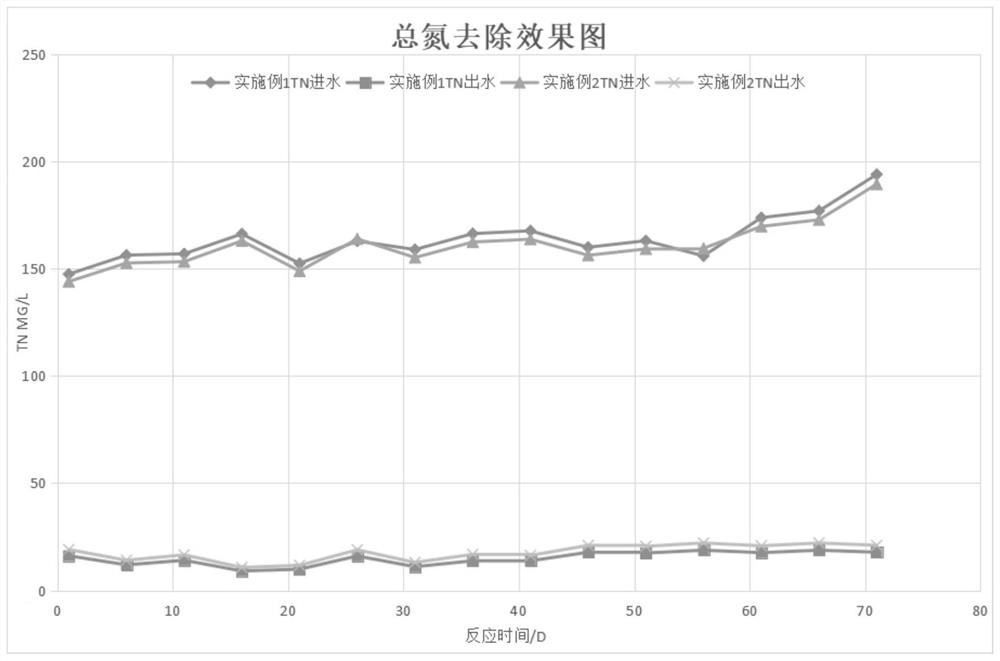

Embodiment 1

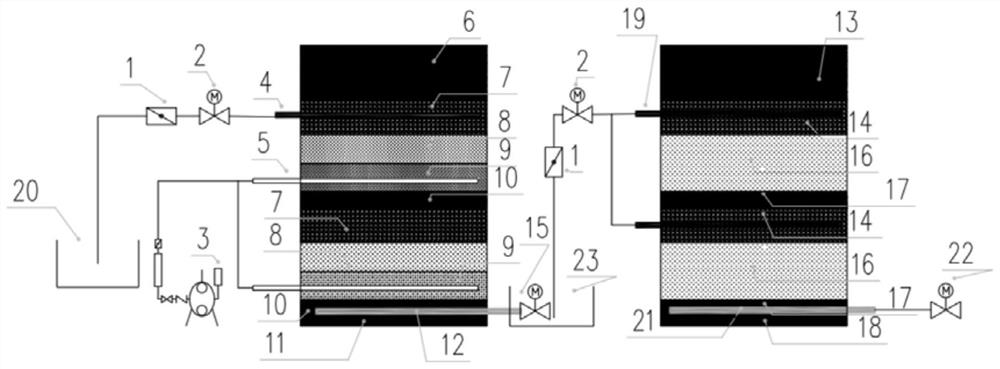

[0040] Such as figure 1 As shown, a kind of diafiltration biochemical treatment system applied to the denitrification of the infiltration system of the present invention comprises a nitrification sump, a nitrification diafiltration biochemical unit, a denitrification sump and a denitrification diafiltration biochemical unit, wherein the nitrification sump The inorganic ammonia nitrogen wastewater in the pool is intermittently and quantitatively or continuously lifted by the lifting pump to the nitrification and filtration biochemical unit and the denitrification and filtration biochemical unit for uniform water distribution, and then flows into the denitrification sump through the nitrification outlet pipe, and then enters through the lift pump. Denitrification diafiltration biochemical unit;

[0041] The biochemical unit of nitrification and filtration is mainly a two-layer reaction structure. The soil cover layer 6, the cobblestone cloth water layer 7, the ceramsite reaction...

Embodiment 2

[0055] Such as figure 1 As shown, a kind of diafiltration biochemical treatment system applied to the denitrification of the infiltration system of the present invention comprises a nitrification sump, a nitrification diafiltration biochemical unit, a denitrification sump and a denitrification diafiltration biochemical unit, wherein the nitrification sump The inorganic ammonia nitrogen wastewater in the pool is intermittently and quantitatively or continuously lifted by the lifting pump to the nitrification and filtration biochemical unit and the denitrification and filtration biochemical unit for uniform water distribution, and then flows into the denitrification sump through the nitrification outlet pipe, and then enters through the lift pump. Denitrification diafiltration biochemical unit;

[0056] The biochemical unit of nitrification and filtration is mainly a two-layer reaction structure. The soil cover layer 6, the cobblestone cloth water layer 7, the ceramsite reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com