A through-hole manufacturing method, an array substrate manufacturing method and an array substrate

A manufacturing method and array substrate technology, applied in the field of array substrates, can solve problems such as high cost and complicated manufacturing process, and achieve the effect of reducing manufacturing cost and simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

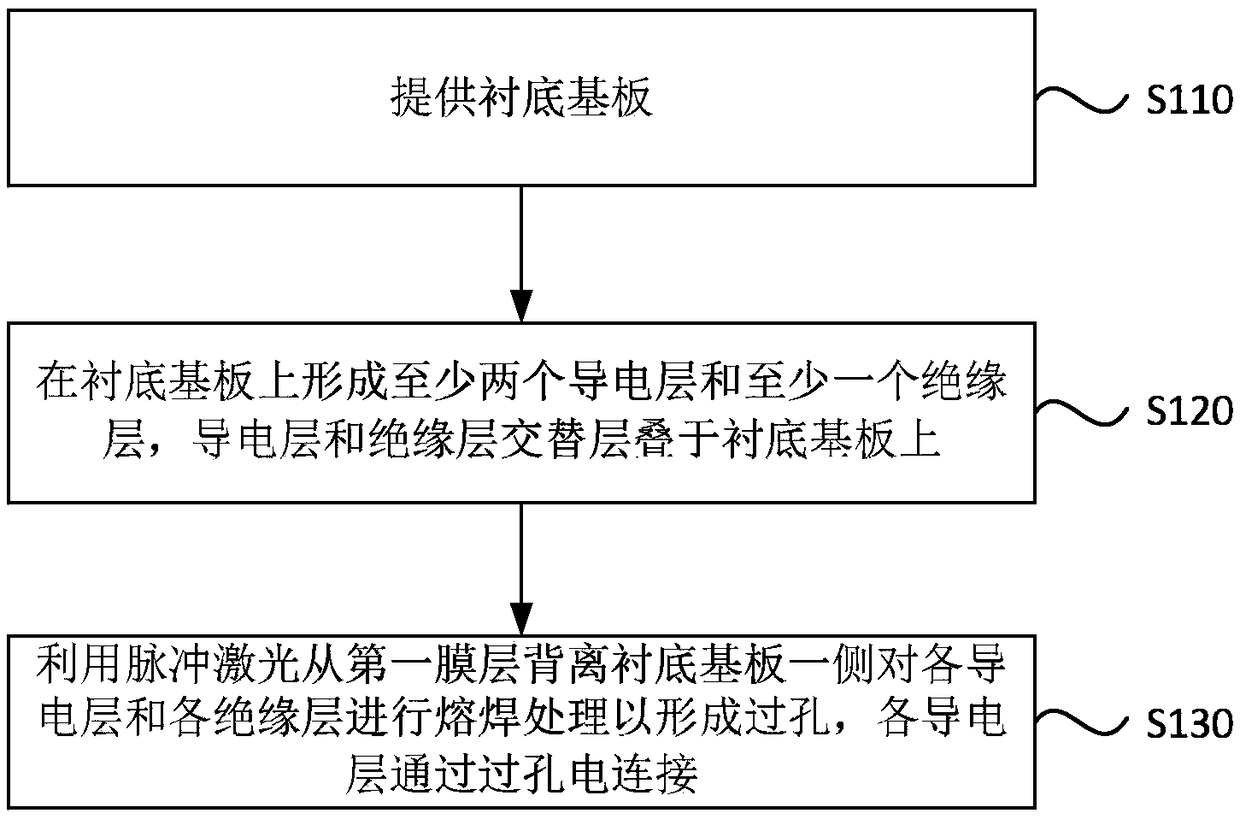

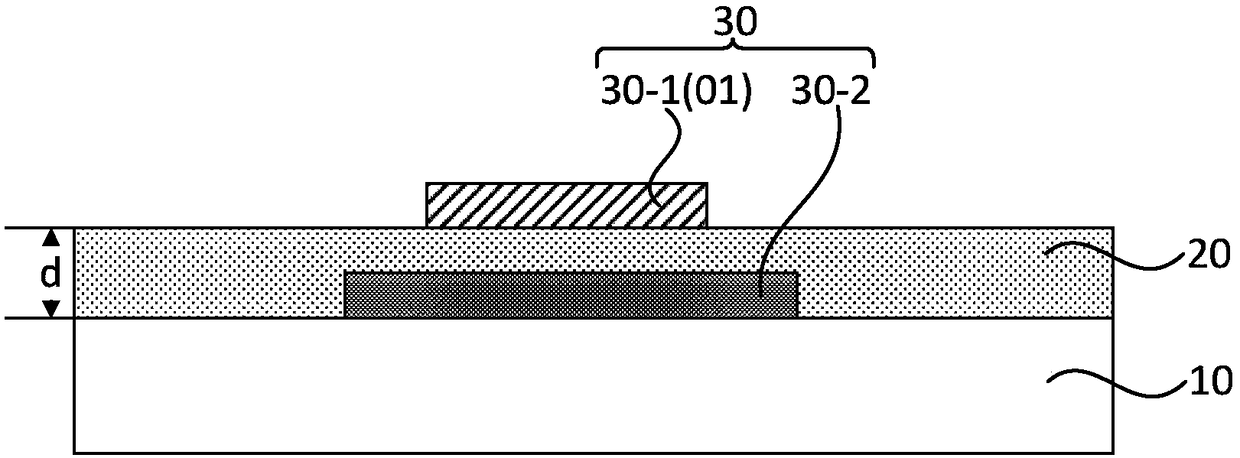

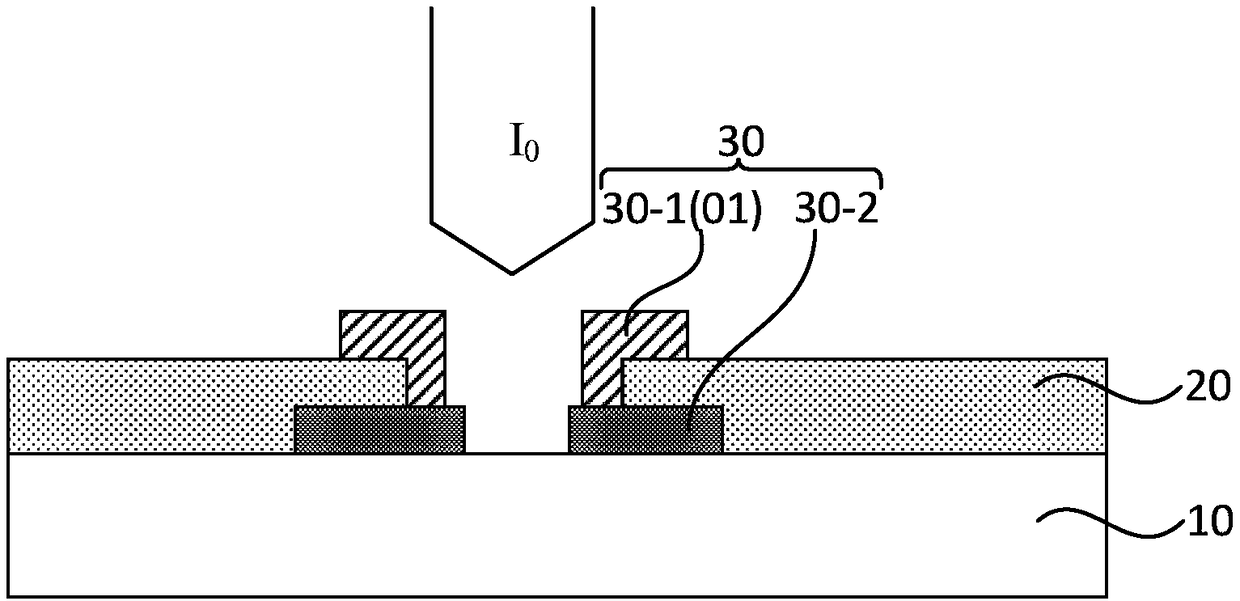

[0036] figure 1 It is a flow chart of a via hole manufacturing method provided by Embodiment 1 of the present invention. Figure 2-Figure 3 It is a schematic diagram of the structure of a conductor device in the process of forming a via hole by using a via hole manufacturing method provided in Embodiment 1 of the present invention. Combine below figure 1 and figure 2 , the manufacturing method of the via hole will be described in detail.

[0037] see figure 1 , the manufacturing method of the via includes:

[0038] S110, providing a base substrate.

[0039] see figure 2 , providing a base substrate 10 .

[0040] S120, forming at least two conductive layers and at least one insulating layer on the base substrate, where the conductive layers and the insulating layers are alternately stacked on the base substrate.

[0041] see figure 2 , at least two conductive layers 30 and at least one insulating layer 20 are formed on the base substrate 10 , and the conductive laye...

Embodiment 2

[0053] Figure 5 It is a flow chart of a via hole manufacturing method provided by Embodiment 2 of the present invention. Figure 6 It is a schematic structural diagram of a semiconductor device in the process of forming a via hole by using a via hole manufacturing method provided in Embodiment 2 of the present invention. Compared with Embodiment 1, this embodiment optimizes S130 to provide a mask plate, the mask plate includes at least one light-transmitting region and a non-light-transmitting region surrounding the light-transmitting region; place the mask plate on the first film layer The side away from the base substrate; using a pulsed laser to weld each conductive layer and each insulating layer from the side of the mask away from the first film layer to form via holes, and each conductive layer is electrically connected through the via holes.

[0054] Specifically, see Figure 5 and Figure 6 , the manufacturing method of the via includes:

[0055] S110, providing a...

Embodiment 3

[0065] Embodiment 3 of the present invention also provides a method for manufacturing an array substrate, and the method for manufacturing the array substrate includes the method for manufacturing via holes provided in any embodiment of the present invention.

[0066] In the manufacturing method of the array substrate provided by the embodiment of the present invention, each conductive layer and each insulating layer are welded from the side of the first film layer away from the base substrate by using a pulsed laser to form via holes, and each conductive layer passes through the via holes The electrical connection can replace the yellow light process. Only one welding process is required to realize the electrical connection of multiple conductive layers, which solves the problem of when multiple conductive layers need to be electrically connected during the production process of the existing display panel. It is necessary to use the yellow light process to etch each insulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com