SF6 gas electronic control inflator

An electronic control, SF6 technology, applied in gas/liquid distribution and storage, container filling method, container discharge method, etc. Safe and reliable operation and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

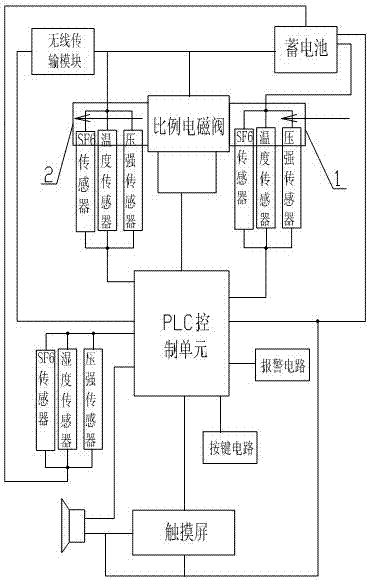

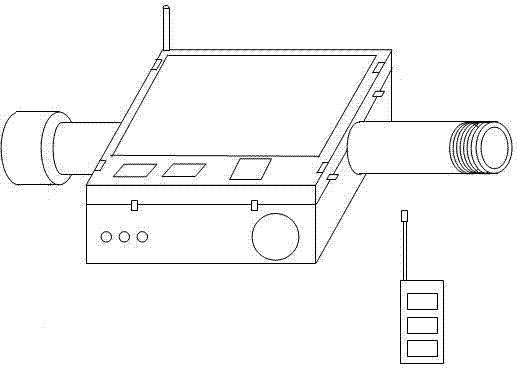

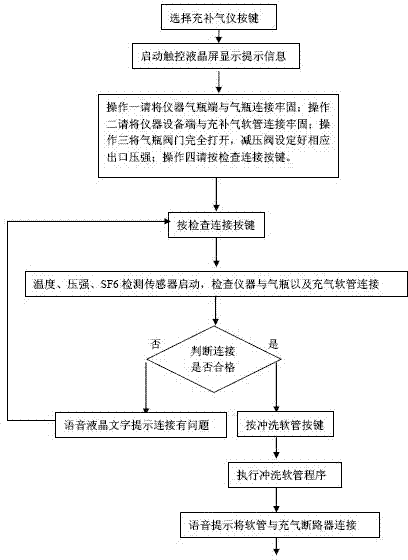

[0029] Such as Figure 1-2 As shown, a SF6 gas electronically controlled inflator includes a housing, the housing includes an upper end cover and a lower end cover, the upper end cover and the lower end cover are clamped and connected, and the contact between the upper end cover and the lower end cover is provided. There is a sealing waterproof strip. The inflator also includes a PLC control unit, a touch screen, a proportional solenoid valve, a wireless transmission module, a power supply, a temperature sensor, a humidity sensor, a pressure sensor, an SF6 sensor, an alarm circuit, a key circuit and a remote controller.

[0030] The PLC control unit controls the opening and closing degree of the proportional solenoid valve according to the collected information, the power supply supplies power to each module in the inflator, the wireless transmission module, the loudspeaker, and the touch screen are electrically connected to the PLC control unit, and the PLC control The unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com