High-yield-ratio, high-strong toughness cast martensite stainless steel and production method thereof

A martensitic stainless steel, high strength and toughness technology, applied in the field of metal materials, can solve unsatisfactory problems, achieve high resistance to cavitation erosion and sediment wear, shorten melting time, ensure welding processability and resistance to underwater fatigue performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

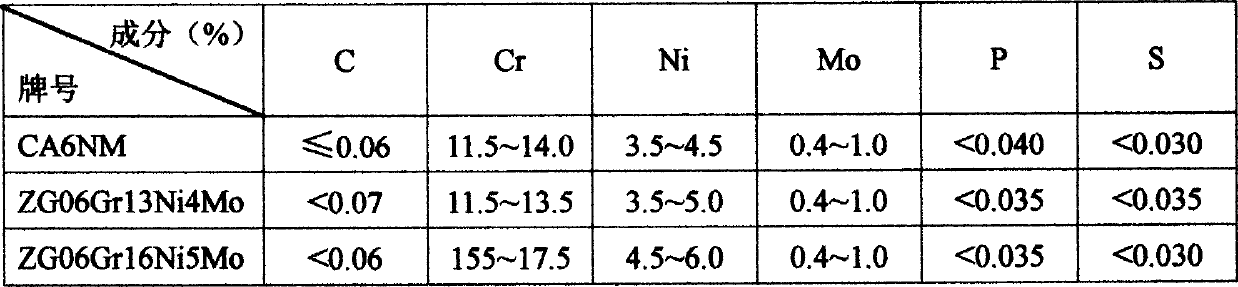

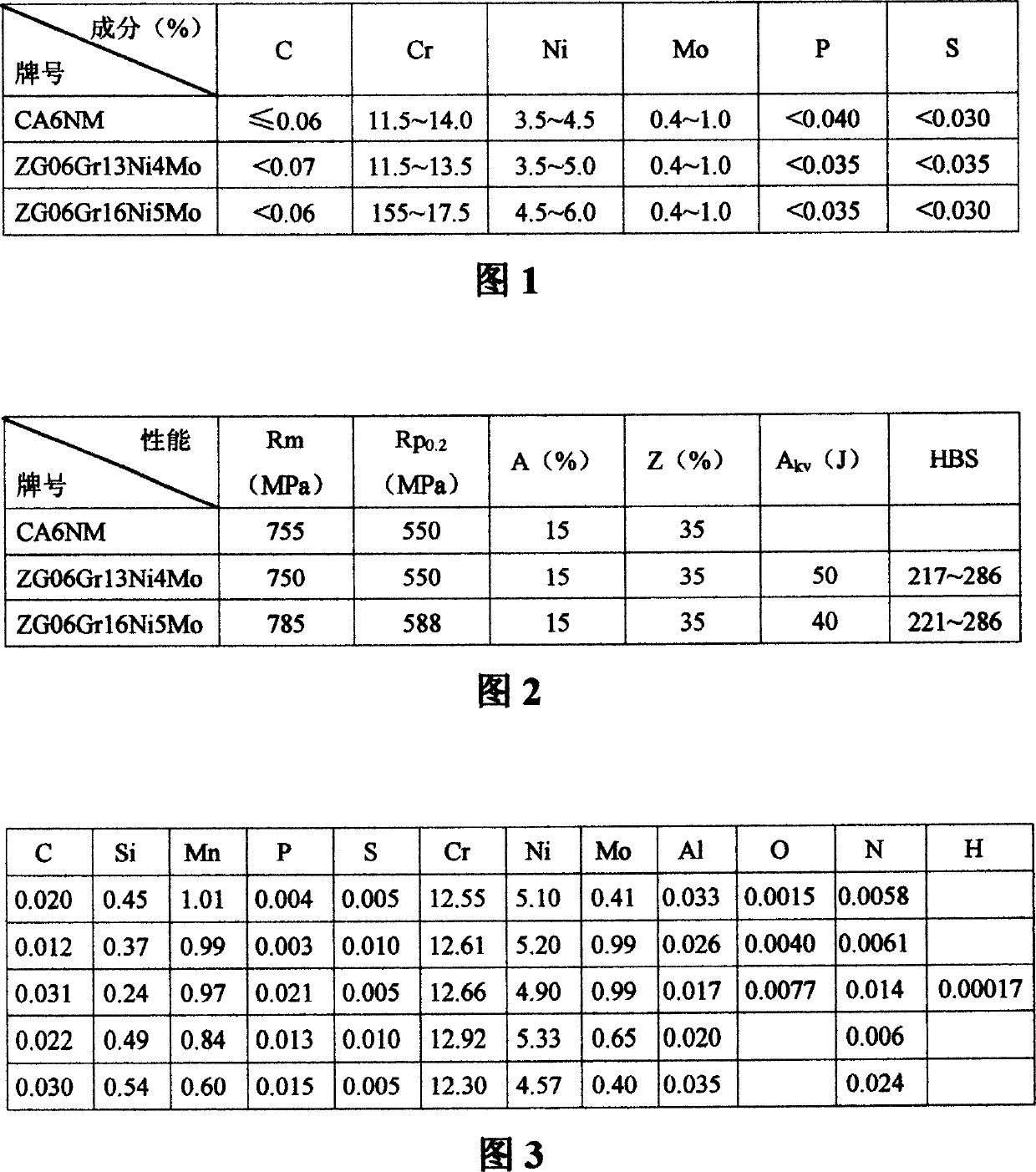

[0067] The chemical composition of cast martensitic stainless steel with high yield ratio and high strength and toughness contains: C0.012%, Cr11%, Ni6.00%, Mn0.60%, Si0.24%, Mo0.50%, Al0.14%, P0.003%, S0.005%, and the balance is Fe.

Embodiment 2

[0069] The chemical composition of cast martensitic stainless steel with high yield ratio and high strength and toughness contains: C0.020%, Si0.45%, Mn1.01%, P0.004%, S0.005%, Cr12.55%, Ni5.1 %, Mo0.41%, Al0.033%, [O] 0.0015%, [N] 0.0058%, and the balance is iron.

Embodiment 3

[0071] The chemical composition of cast martensitic stainless steel with high yield ratio and high strength and toughness contains: C0.012%, Si0.37%, Mn0.99%, P0.003%, S0.010%, Cr12.61%, Ni5.20 %, Mo0.99%, Al0.026%, [O] 0.0040%, [N] 0.0061%, and the balance is Fe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com