Separate combination type air heat regenerator

A technology of air heat and recycler, applied in indirect heat exchangers, using air flow as shielding, space heating and ventilation, etc., can solve the problems of not making full use of environmental conditions, increasing high-quality energy consumption, and high-quality energy waste, etc. problems, to achieve excellent heat transfer efficiency, significant energy-saving effect, and energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

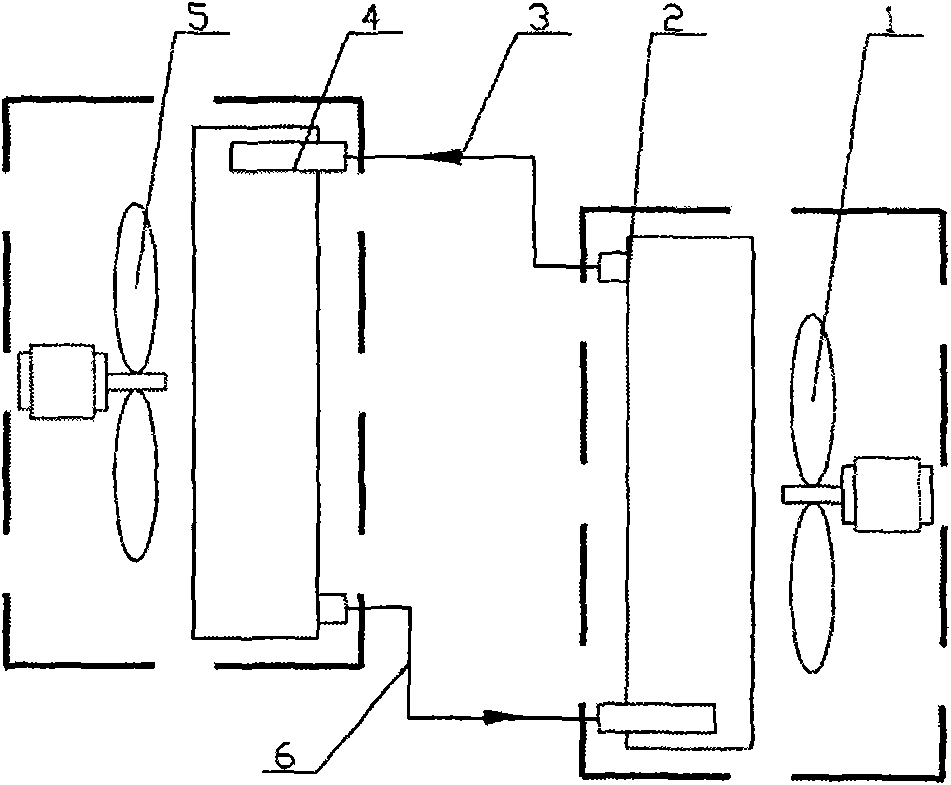

[0029] see figure 1 , the separated and combined air heat recovery device includes two heat exchangers, one is the hot side heat exchanger 2, and the other is the cold side heat exchanger 4; A cold-side fan 5 is arranged outside the heat exchanger 4 .

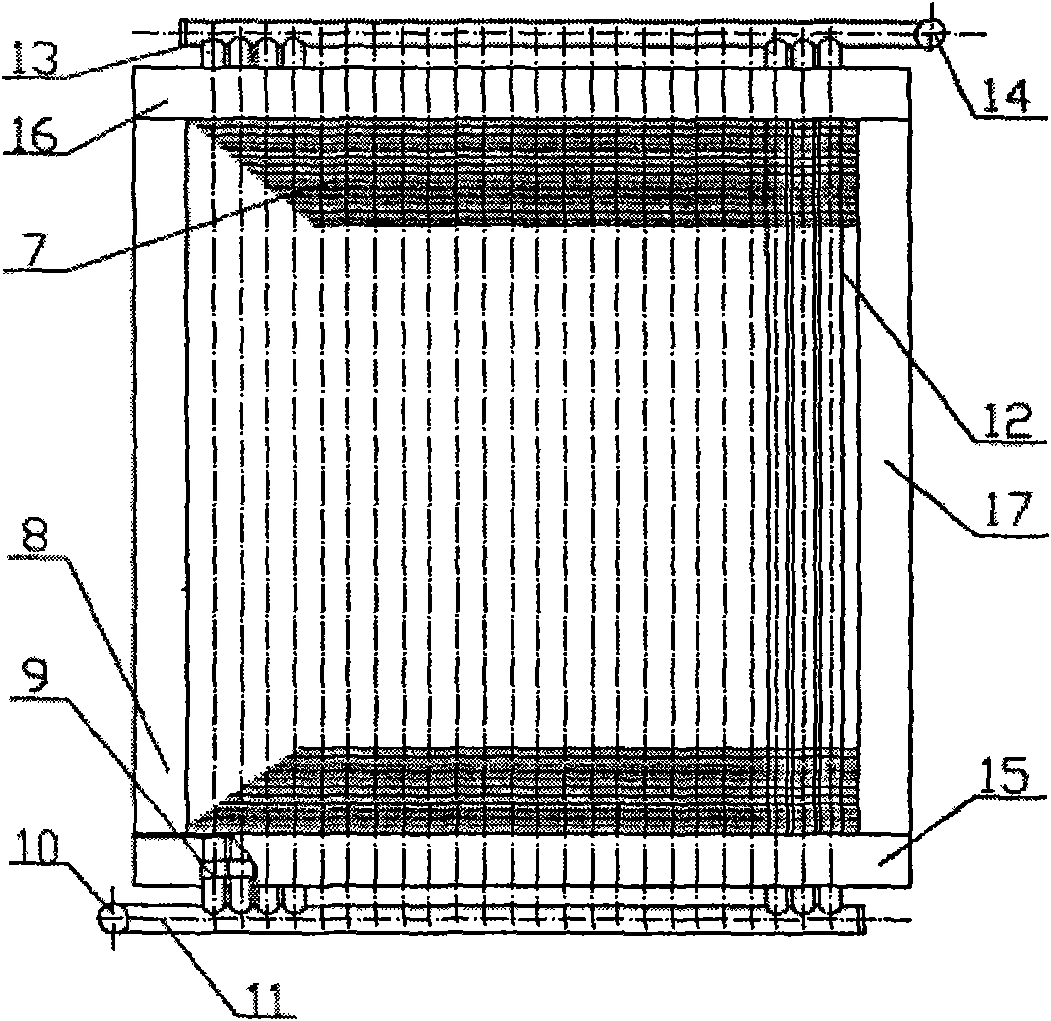

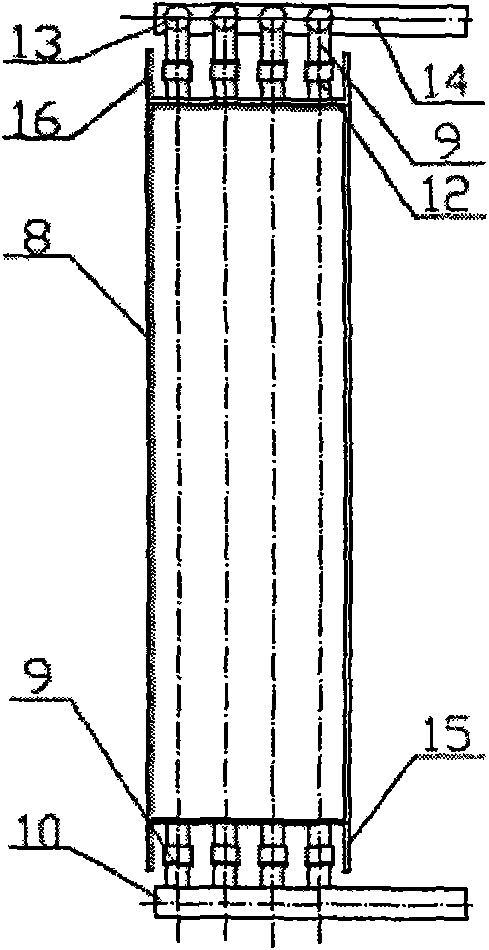

[0030] see figure 2 , image 3 and Figure 4 , the heat exchanger includes four rows of heat exchange tubes, and each row of heat exchange tubes includes more than ten heat exchange tubes; In the frame-type frame, the two ends of each heat exchange tube 12 extend to the outside of the bottom plate 15 and the top plate 16 respectively; Gas manifold 13, one end of four gas manifolds 13 is connected with inlet or outlet pipe 14, one end of inlet or outlet pipe 14 is a closed end, and the other end is an inlet or outlet; each row of heat exchange tubes The lower extension ends of the heat exchange tubes 12 are respectively connected to the liquid header pipe 11 through the connecting pipe 9, and one end of the four liquid hea...

Embodiment 2

[0037] see Figure 5 , Figure 6 and Figure 7 One end of the four gas collection pipes 13 is connected to two inlet or outlet pipes 14 respectively, one end of the two inlet or outlet pipes 14 is a closed end, and the other end is an inlet or outlet end; the four liquid collection pipes One end of the manifold 11 is connected to two outlet or inlet pipes 10 in pairs; one end of the two outlet or inlet pipes 10 is a closed end, and the other end is an outlet or inlet end.

[0038] The medium liquid level in the hot side heat exchanger is higher than the medium liquid level in the cold side heat exchanger, and the height difference is 20 mm.

[0039] Others are with embodiment 1.

Embodiment 3

[0041] see Figure 8 , Figure 9 and Figure 10 , the other ends of the four gas manifolds 13 are all gas inlet or outlet ends; the other ends of the four liquid manifolds 11 are all outlet or liquid inlet ends.

[0042] The medium liquid level in the hot side heat exchanger is higher than the medium liquid level in the cold side heat exchanger, with a height difference of 10mm.

[0043] Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com