Spherical high-frequency vector sensor vibration velocity channel and sound pressure channel integral processing method

A vector sensor and sound pressure channel technology, applied in the direction of measuring vibration, instruments, measuring devices, etc., can solve the problems of small size and technical difficulty, and achieve the effect of small size and saving layout space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

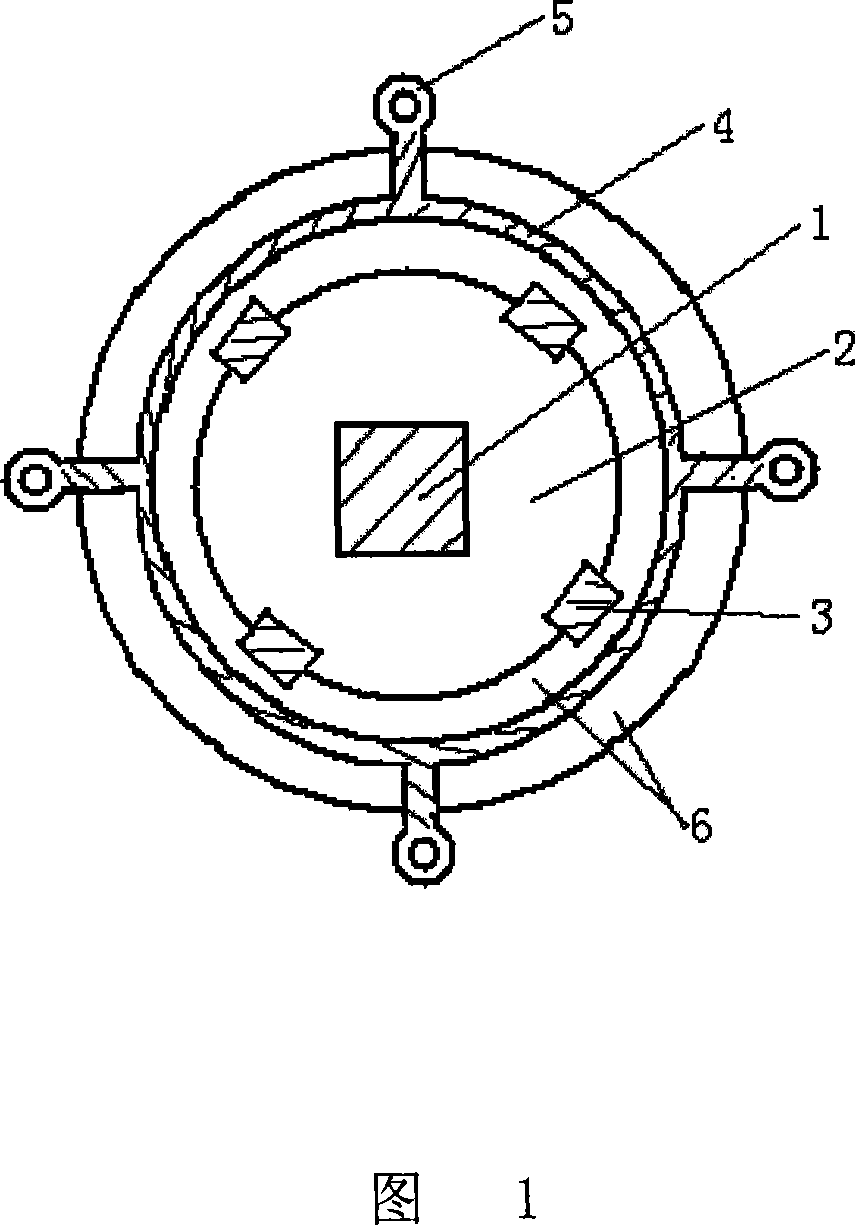

[0018] The integrated processing method of the vibration velocity channel and the sound pressure channel of the spherical high-frequency vector sensor in this embodiment is carried out in the following steps: first, all parts are cleaned, the sensor [1] is placed in a spherical mold, and eight acoustic The pressurized hydrophone [3] is also fixed on the mould, and the prepared low-density composite material [2] is poured into the spherical mold. After the low-density composite material [2] is completely cured, the mold is removed and cleaned. Put the obtained sphere with eight sound pressure hydrophones [3] inlaid on its outer surface into another outer mold, and put the ring [4] with four hanging rings [5] into a spherical low-density compound The waist position of the material [2]. Accurately adjust the position of the ring [4] to ensure that the ring [4] does not contact the ball surface of the low-density composite material [2]. Then the prepared sound-transmitting materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com