Treatment and reuse system and method for up-to-standard discharged painting wastewater

A waste water and coating technology, which is applied in water/sewage treatment, heating water/sewage treatment, light water/sewage treatment, etc., can solve the problems of increased treatment difficulty, poor biodegradability, and difficult reuse treatment, etc., to achieve Effects of Organic Pollutants and Salt Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

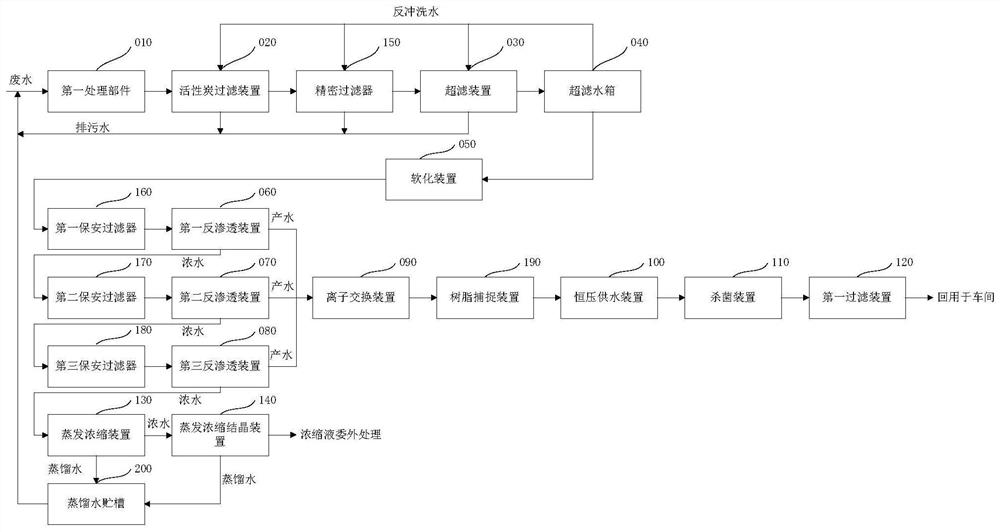

Embodiment 1

[0155] The coating wastewater produced in the production process of a large-scale domestic joint venture commercial vehicle factory is discharged up to the standard after being treated by the original wastewater station for physical, chemical, biochemical, and sedimentation. The main pollutants are: pH: 6-9, CODCr: 150-200mg / L, TDS: 1480~2200mg / L, conductivity: 1700~2500us / cm, HCO 3- : 500~550mg / L, PO4 3- : 8~15mg / L, SO4 2- : 500~600mg / L, NO 3- : 25~35mg / L, Cl - : 15~25mg / L, F - :8~15,K + (Element): 138~150mg / L, Na + (element): 370~400mg / L, S (element): 220~250mg / L, P (element): 4~8mg / L, B (element): 15~20mg / L, Ca (element): 25~ 35mg / L (that is, the discharge of wastewater when the coating reaches the standard). According to the environmental impact assessment and the company's environmental protection discharge requirements, it is necessary to carry out advanced treatment on the discharged water and reuse it in the production workshop to meet the requirements of zero ...

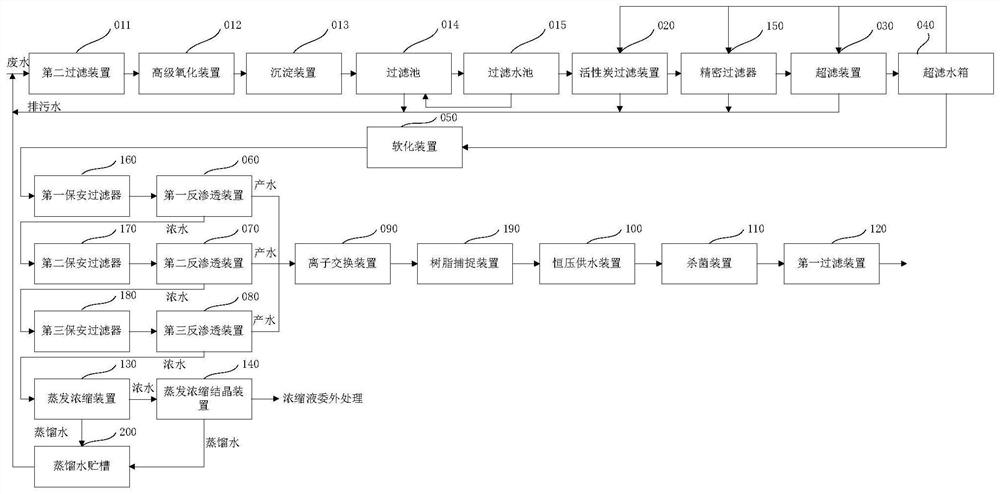

Embodiment 2

[0174] The first treatment unit 010 described in Embodiment 1 is replaced by: comprising a second filter device 011, an ozone oxidation device 016, a biological aerated filter 017, a filter pool 015 and a sand filter 018 in fluid communication in sequence, the sand filter 018 communicates with the activated carbon filter device 020. Others are the same as in Example 1.

[0175] Table 4 The main equipment involved in the advanced processing and recycling system

[0176]

[0177] After the treatment and reuse system of the wastewater discharged from the coating up to the standard is put into operation, the quality of the effluent water is high-quality and stable, and the indicators are as follows in Table 5 and Table 6:

[0178] Table 5: Wastewater influent and effluent water quality treatment effect indicators The indicators of the discharged wastewater after painting are up to standard are as follows:

[0179]

[0180]

[0181] Table 6: The main water quality indica...

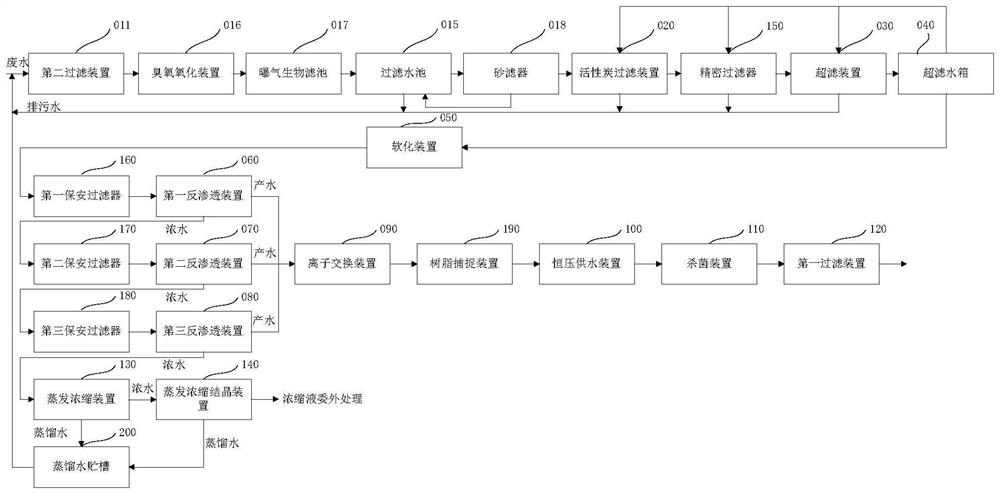

Embodiment 3

[0184] The first processing unit 010 in Embodiment 1 is replaced by: the first processing unit 010 includes a coagulation and flocculation reaction device or an electrocoagulation device 019, a sedimentation device 013, a filter tank 014 and a filter water tank 015 in fluid communication in sequence, The filter pool 015 communicates with the activated carbon filter device 020 . Others are the same as in Example 1.

[0185] Table 7 The main equipment involved in the advanced processing and recycling system

[0186]

[0187] After the treatment and reuse system of the discharge wastewater that reaches the painting standard is put into operation, the quality of the effluent water is high-quality and stable, and the indicators are as follows in Table 8 and Table 9:

[0188] Table 8: Wastewater influent and effluent water quality treatment effect indicators The various indicators of the discharged wastewater after painting are up to standard are as follows:

[0189] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com