Treating process of printing and dyeing waste water

A treatment process, technology for printing and dyeing wastewater, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve printing and dyeing wastewater's poor biodegradability and difficulty in meeting primary and secondary discharge requirements and other problems, to achieve the effect of stable treatment effect, low operating cost and meeting water quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

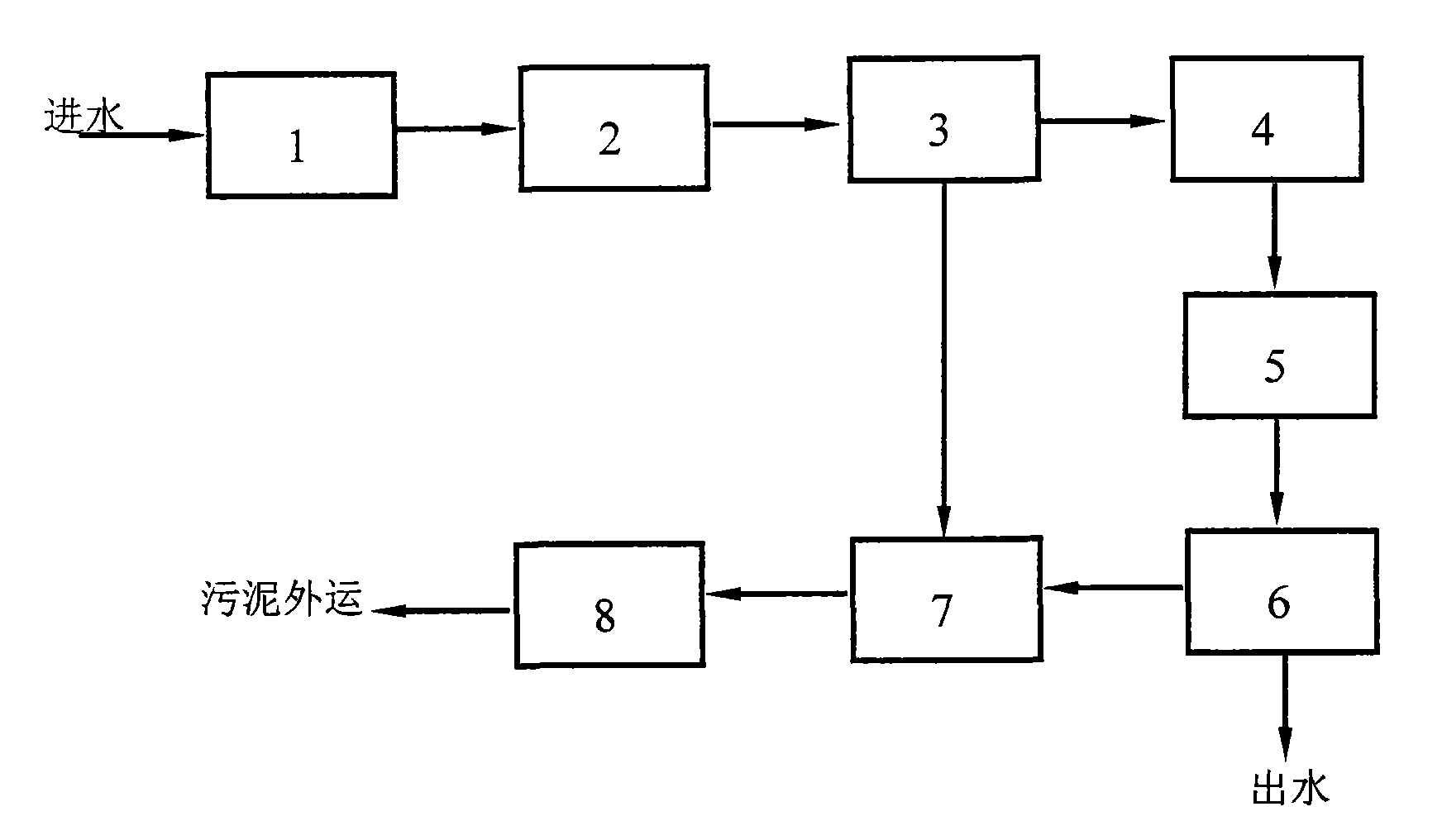

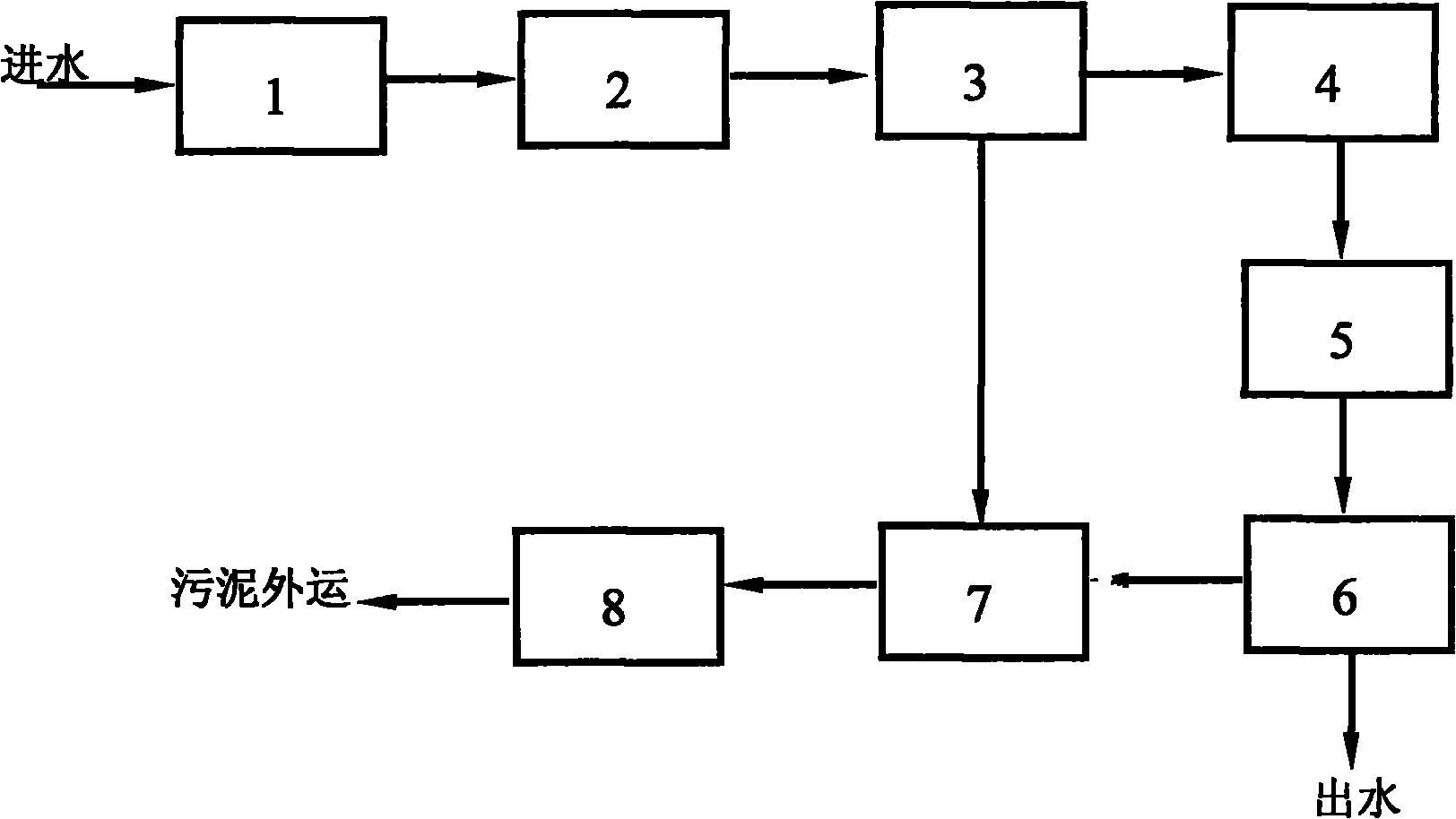

[0013] The present invention handles technical process such as figure 1 As shown, it consists of grid 1, regulating tank 2, sedimentation tank 3, decolorization fluidized bed 4, hydrolytic acidification tank 5, aerobic membrane bioreactor 6, sludge thickening tank 7 and sludge dewatering tank 8, and the specific implementation The way is as follows:

[0014] 1. Printing and dyeing wastewater passes through the grid 1 to intercept larger suspended and floating substances to reduce the processing load of subsequent treatment structures, and the generated grid slag is transported outside for treatment.

[0015] 2. The printing and dyeing wastewater treated by the grid 1 is adjusted by the regulating tank 2 for water quantity and quality, and then enters the sedimentation tank 3 to remove suspended matter.

[0016] 3. The effluent from the sedimentation tank 3 enters the decolorization fluidized bed 4, and decolorizes the wastewater through the manganese sand catalyzed primary ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com