Unconventional oil field exploration and development fracturing flowback fluid reuse treatment method

A technology of fracturing flowback fluid and treatment methods, which is applied in mining wastewater treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc. It can solve problems such as oilfield injection-production imbalance and formation damage, and reduce water turbidity. degree and petroleum content, reduce the salinity of water body, and stabilize the water quality of produced water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

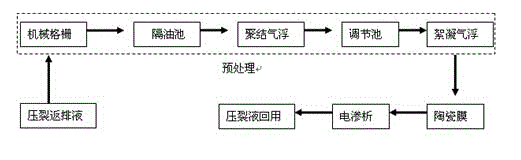

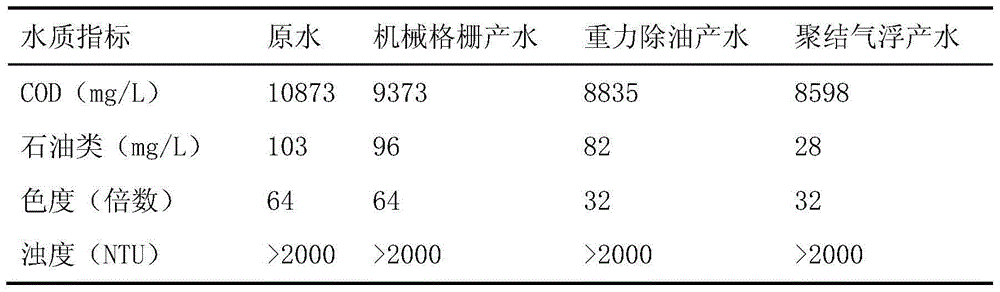

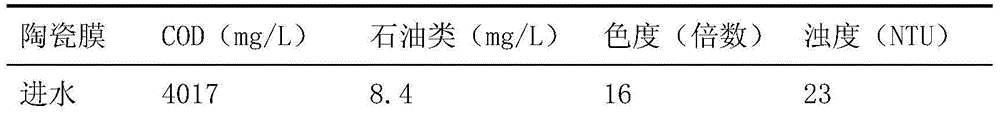

[0028] The fracturing flowback fluid of an unconventional development well in an oilfield is pumped into the mechanical grid. The width of the mechanical grid is 1mm. The fracturing flowback fluid enters the oil separation tank and the coalescence air flotation tank successively after being filtered by the mechanical grid. The hydraulic retention time in both the oil separation tank and the coalescence air flotation tank is 30 minutes, and the filler in the coalescence air flotation tank is made of polypropylene double sinusoidal plates. The COD removal rate in the water is about 21% after the coalescence air flotation tank, and the oil removal effect is more obvious. The oil content in the water produced by the coalescence air flotation tank can be stably controlled below 30mg / L, and the removal rate is over 70%. This is the result of the combined effect of polypropylene coalescing filler and air flotation device for enhanced degreasing; the chroma of the water body is reduced...

Embodiment 2

[0043] The fracturing flowback fluid of an unconventional development well in an oilfield is pumped into the mechanical grid. The width of the mechanical grid is 1mm. The fracturing flowback fluid enters the oil separation tank and the coalescence air flotation tank successively after being filtered by the mechanical grid. The hydraulic retention time in both the oil separation tank and the coalescence air flotation tank is 25 minutes, and the filler in the coalescence air flotation tank is made of polypropylene double sinusoidal plates. The COD removal rate in the water is 20.5% after the coalescence air flotation tank, and the oil removal effect is more obvious. The oil content in the water produced by the coalescence air flotation tank can be stably controlled below 28mg / L, and the removal rate reaches 72.5%, which is The results of the joint action of polypropylene coalescing filler and air flotation device to enhance degreasing; the chroma of the water body is reduced from...

Embodiment 3

[0057] The fracturing flowback fluid of an unconventional development well in an oilfield is pumped into the mechanical grid. The width of the mechanical grid is 1mm. The fracturing flowback fluid enters the oil separation tank and the coalescence air flotation tank successively after being filtered by the mechanical grid. The hydraulic retention time in both the oil separation tank and the coalescence air flotation tank is 35 minutes, and the filler in the coalescence air flotation tank is made of polypropylene double sinusoidal plates. The removal rate of COD in the water after the coalescence air flotation tank is 20.8%, and the removal effect of petroleum is relatively obvious. The content of petroleum in the water produced by the coalescence air flotation tank can be stably controlled below 30mg / L, and the removal rate is over 70%. It is the result of the joint action of polypropylene coalescing filler and air flotation device to strengthen degreasing; the chroma of the wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com