Technology for treatment of mariculture circulating water of biological filter and membrane filtration

A technology of mariculture and combined treatment, applied in the field of water treatment technology of mariculture, can solve the periodic fluctuations in the removal effect of effluent particles and organic matter, the membrane filtration process does not have the ability to circulate and purify aquaculture water, and the filter has the ability to control and regulate pathogenic bacteria It can achieve the effect of high safety and stability, low operating cost and reducing the amount of membrane used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

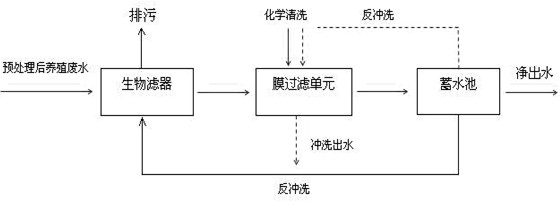

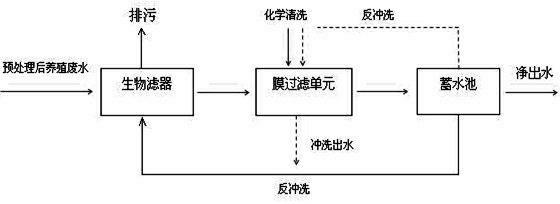

Method used

Image

Examples

Embodiment 1

[0030] The wastewater detection indicators in this example are: total ammonia nitrogen=0.25mg / L, COD=12mg / L, nitrite nitrogen=0.004mg / L, SS=250mg / L, microbial content=10 7 CFU / mL.

[0031] The biofilter and membrane filtration combined treatment process of marine aquaculture circulating water in this embodiment comprises the following steps:

[0032] (1) Pretreatment: pretreat the wastewater to be treated through grid filtration and foam separation;

[0033] (2) Preliminary filtration of the biological filter: the pretreated wastewater enters the biological filter, and the biological filter is filled with bamboo ring fillers accounting for 70% of the total volume. After 75 days of film formation, the bamboo ring fillers have mature biofilms on the surface. The hydraulic retention time of the bamboo ring filler is maintained at 0.5h. Under the conditions of temperature 22°C, DO>6.7mg / L, and pH value of 7.3, the wastewater is filtered through the filler and biofilm contact oxid...

Embodiment 2

[0042] The wastewater detection indicators in this example are: total ammonia nitrogen=2.20mg / L, COD=4mg / L, nitrite nitrogen=0.091mg / L, SS=15mg / L, microbial content=10 5 CFU / mL.

[0043] The biofilter and membrane filtration combined treatment process of marine aquaculture circulating water in this embodiment comprises the following steps:

[0044] (1) Pretreatment: pretreat the wastewater to be treated through grid filtration and foam separation;

[0045] (2) Preliminary filtration of biological filter: The pretreated wastewater enters the biological filter, and the biological filter is filled with bamboo ring fillers accounting for 70% of the total volume. After 60 days of film formation, the bamboo ring fillers have mature biofilms on the surface. The hydraulic retention time of the bamboo ring filler is maintained at 0.75h. Under the conditions of temperature 14°C, DO>6.7mg / L, and pH value of 8.0, the waste water is filtered through the filler and contacted with the biofi...

Embodiment 3

[0054] The wastewater detection indicators in this example are: total ammonia nitrogen=1.50mg / L, COD=8mg / L, nitrite nitrogen=0.050mg / L, SS=100mg / L, microbial content=10 6 CFU / mL.

[0055] The biofilter and membrane filtration combined treatment process of marine aquaculture circulating water in this embodiment comprises the following steps:

[0056] (1) Pretreatment: pretreat the wastewater to be treated through grid filtration and foam separation;

[0057] (2) Preliminary filtration of the biological filter: the pretreated wastewater enters the biological filter, and the biological filter is filled with bamboo ring fillers accounting for 70% of the total volume. After 70 days of film formation, the bamboo ring fillers have mature biofilms on the surface. The hydraulic retention time of the bamboo ring filler is maintained at 0.65h. Under the conditions of temperature 18°C, DO>6.7mg / L, and pH value of 7.8, the waste water is filtered through the filler and biofilm contact oxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com