Titanium heat exchange tube welded argon shield device and using method thereof

A technology of argon gas protection and heat exchange tube, which is applied to the device, welding equipment, welding accessories, etc. for providing/removing protective gas, which can solve the problems of poor argon gas protection effect, unqualified product quality, and restricting the manufacture of titanium equipment. , to achieve the effect of ensuring process performance and mechanical performance, low cost and saving manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

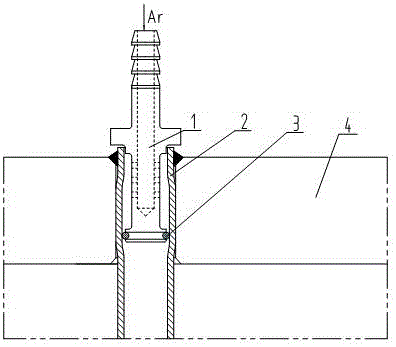

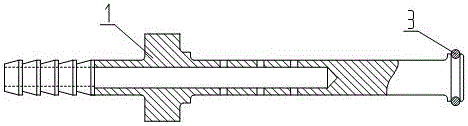

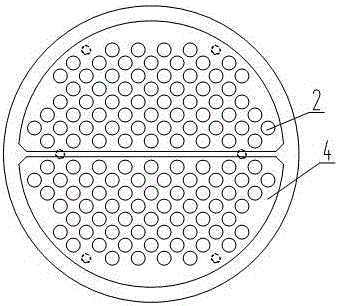

[0018] Such as figure 2 As shown, the present invention provides a titanium heat exchange tube welding argon protection device, which has a structure: a main device 1, an O-shaped rubber sealing ring 3; the main device 1 is tubular, with an air inlet pipe at one end, and another One end is airtight; the main device 1 has two-stage bosses on the side near the intake pipe: the diameter of the large boss is larger than the outer diameter of the heat exchange tube 2, and the diameter of the small boss is slightly smaller than the inner diameter of the heat exchange tube 2; the main device 1 has a convex There are evenly distributed small holes on the side of the tube from the platform to the closed end; the closed end of the main device 1 is provided with an annular groove, and the O-shaped rubber sealing ring is placed in the annular groove.

[0019] There are 8 uniformly distributed small holes on the side of the tube with a diameter of φ6.

[0020] The main device 1 has two s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com