Glass-hard low-frictional coefficient nano-multi-layer amplitude modulation structure coating and preparation method thereof

A technology with low friction coefficient and multi-layer structure, which is applied in the direction of coating, layered products, sputtering coating, etc., can solve the problems that need to be further studied and improved, and the mechanism of coating performance change is different, so as to achieve accurate coating Composition, process stability, high reproducibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

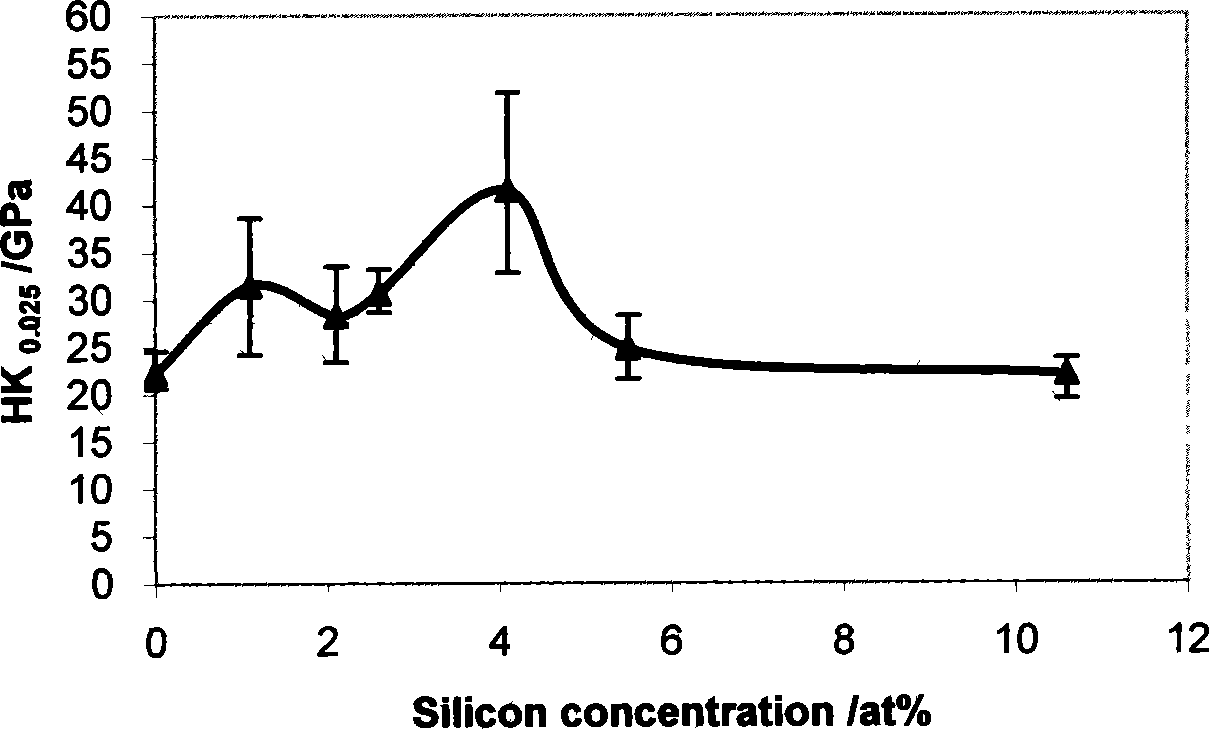

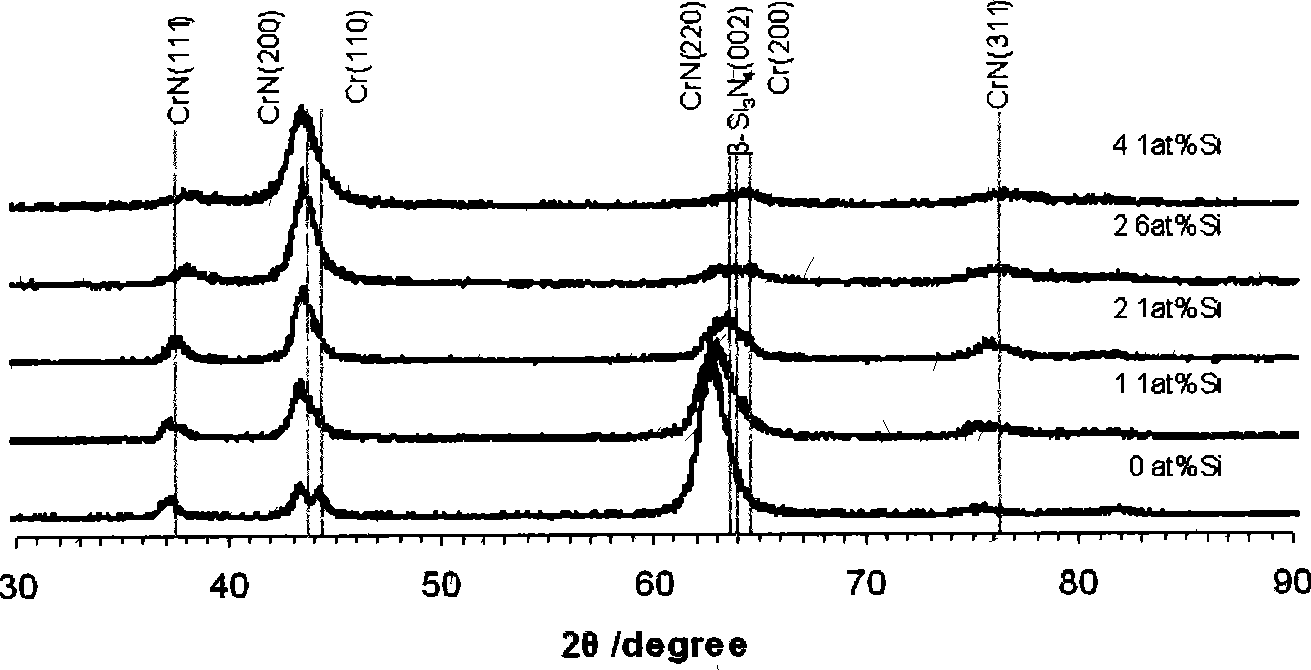

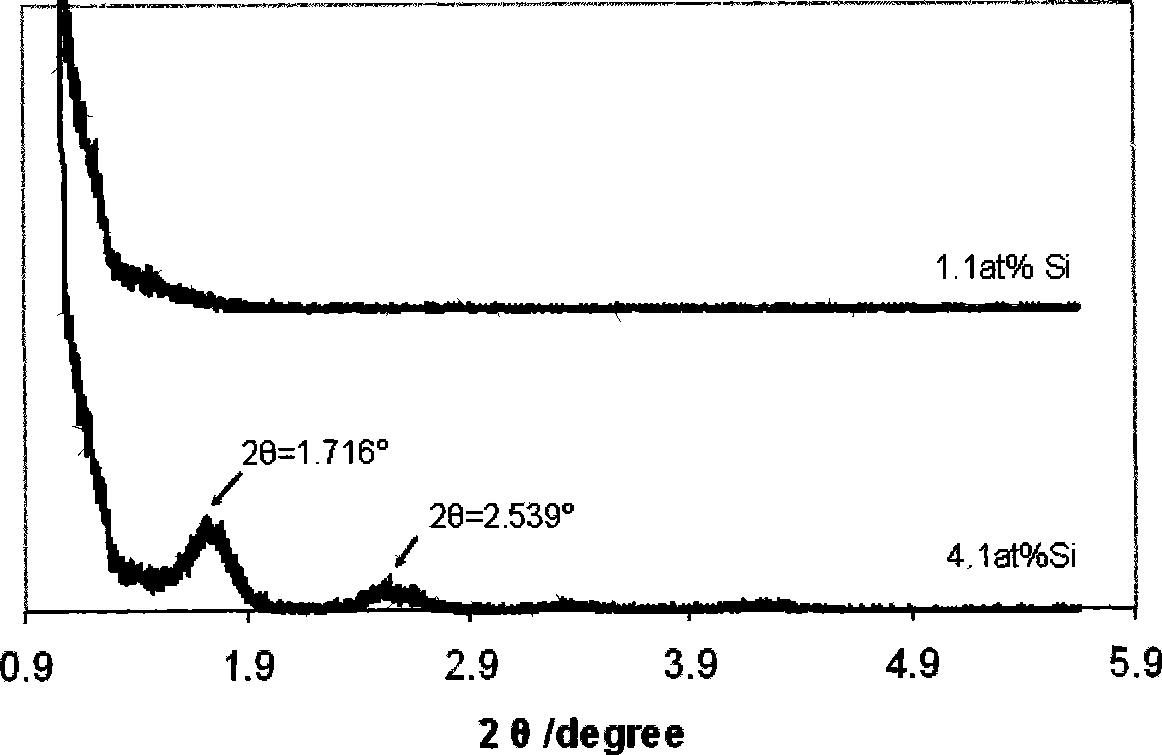

Method used

Image

Examples

Embodiment 1

[0030] Polish the M42 high-speed steel substrate with a hardness of HRC61-63 with 1 μm diamond abrasive paste, and perform ultrasonic cleaning in acetone solution together with (100) single crystal silicon wafers for 20 minutes, and put it into the one-axis rotation of the vacuum chamber of the coating equipment on the sample holder (e.g. Figure 10 shown). Under the condition of 500V bias, the surface of the substrate was cleaned by plasma bombardment for 20 minutes, and then the Cr interface layer was prepared, and the vacuum degree of the back was 2×10 -2 Torr, argon gas flow rate 10sccm, Cr target input power 2kW, bias voltage -60V, plating time 25min. Then pass through nitrogen to form a CrN transition layer for 60 minutes, and other parameters are the same as when preparing the Cr interface layer. Then turn on the Si target, the input power of the Si target is 0.32kW, and other parameters are the same as the previous step. During the entire plating process, the parame...

Embodiment 2

[0039] The input power of the Si target was adjusted to 0.40kW, and all other implementation processes and parameters were the same as those in Embodiment 1.

Embodiment 3

[0041] The input power of the Si target was adjusted to 0.48kW, and all other implementation processes and parameters were the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com