Auxiliary protection gas hood of automatic TIC welder head

A protective gas cover and automatic technology, applied in the direction of providing/removing protective gas devices, welding equipment, welding accessories, etc., can solve the problems of small protection range of welding nozzles, easy oxidation of metal welding, etc., to expand the protection range and avoid The effect of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

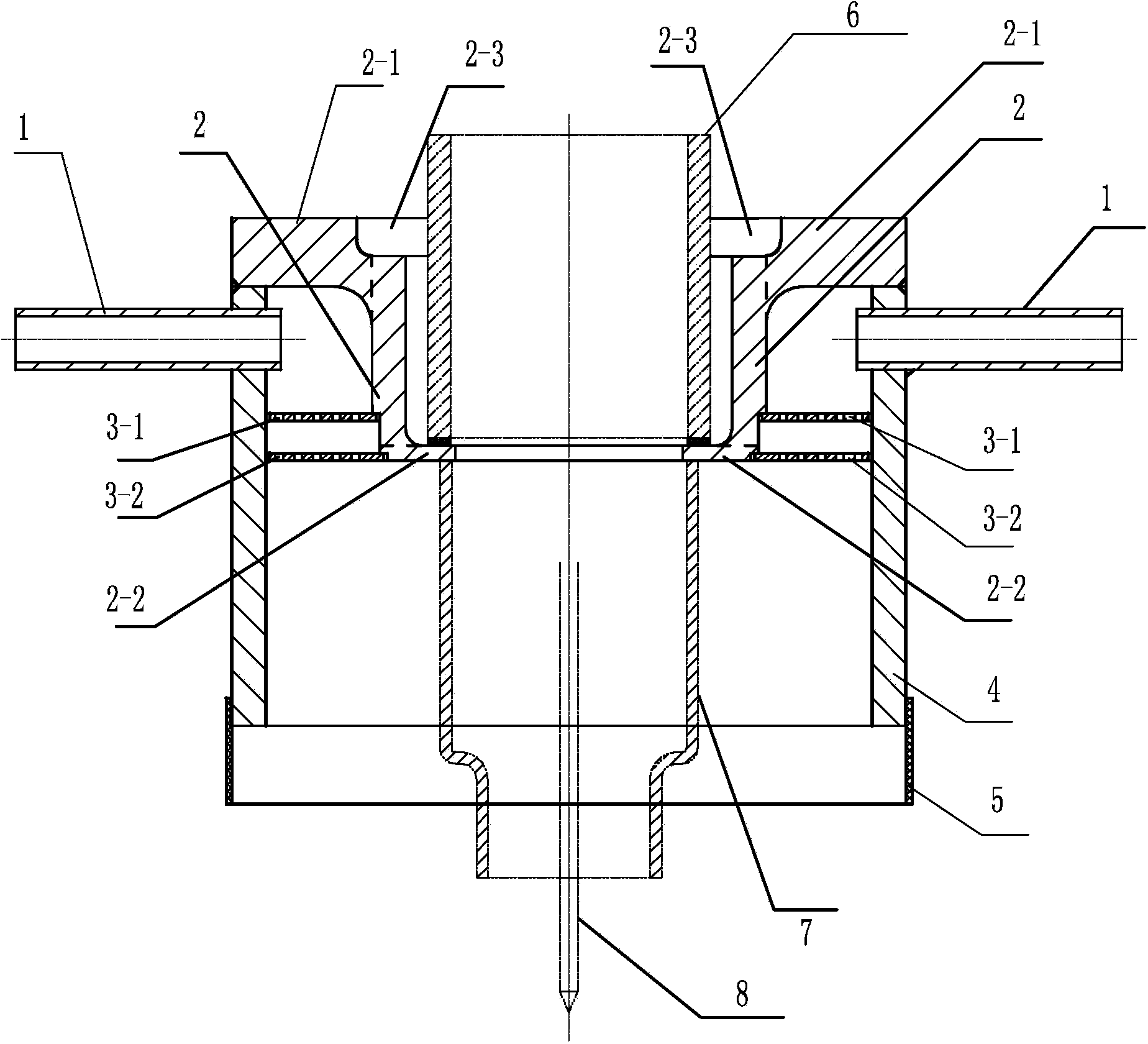

[0017] Specific implementation mode 1, refer to figure 1 Specifically illustrate the present embodiment, the automatic TIG welding machine head auxiliary shielding gas cover described in the present embodiment, it comprises two air guide pipes 1, top cover 2 and stainless steel shell 4;

[0018] The stainless steel casing 4 is a hollow cylinder, and the cylinder of the stainless steel casing 4 is symmetrically provided with two round holes, and the two air guide tubes 1 respectively pass through the two round holes on the cylinder of the stainless steel casing 4 and connect with the stainless steel casing 4. Welding, and the air duct 1 communicates with the interior of the stainless steel shell 4;

[0019] The top cover 2 is a hollow cylinder, and the top circumference of the cylinder is fixed with an annular outer edge 2-1, the annular outer edge 2-1 is coaxial with the top cover 2, and the circular outer edge 2-1 is coaxial with the top cover 2, and the circular outer edge 2...

specific Embodiment approach 2

[0025] Embodiment 2. This embodiment is a further description of the automatic TIG welding machine head auxiliary shielding gas cover described in Embodiment 1. In this embodiment, it also includes two layers of screens 3, the first screen 3-1 and the second mesh plate 3-2 are welded between the outer wall of the upper cylinder side of the top cover 2 and the inner wall of the stainless steel shell 4, and the first mesh plate 3-1 is located on the second mesh plate 3- 2; the first net plate 3-1 and the second net plate 3-2 are located below the air guide port of the air duct 1.

[0026] The argon gas enters the auxiliary protective gas cover through the air duct 1, and then is filtered through the first mesh plate 3-1 and the second mesh plate 3-2 to reduce the turbulent flow of the argon gas, and the argon gas forms a stable auxiliary argon gas around the welding torch. The air flow field, so that the area inside the auxiliary gas hood outside the nozzle of the welding torch ...

specific Embodiment approach 3

[0027] Specific embodiment three. This specific embodiment is a further description of the automatic TIG welding machine head auxiliary protective gas cover described in specific embodiment one. In this embodiment, it also includes a high-temperature tape 5, which is wound on a stainless steel The edge of the lower half of the cylinder of the housing 4.

[0028] The main function of the high-temperature tape is to compensate the gap between the welding torch and the workpiece during the welding process, prevent the auxiliary shielding gas cover from rigid friction with the workpiece, and at the same time play the function of gathering argon to prevent titanium alloys and other easily oxidized metals during welding. The workpiece is oxidized, which affects the properties of titanium alloys and other easily oxidized metals.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com