Soybean milk machine capable of completely smashing pulping materials

A technology for pulping materials and soymilk machines, applied in dairy products, food preparation, food science and other directions, can solve problems such as inability to achieve results, and achieve the effects of improving the crushing effect, avoiding the paste tube and bottom, and improving the beating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

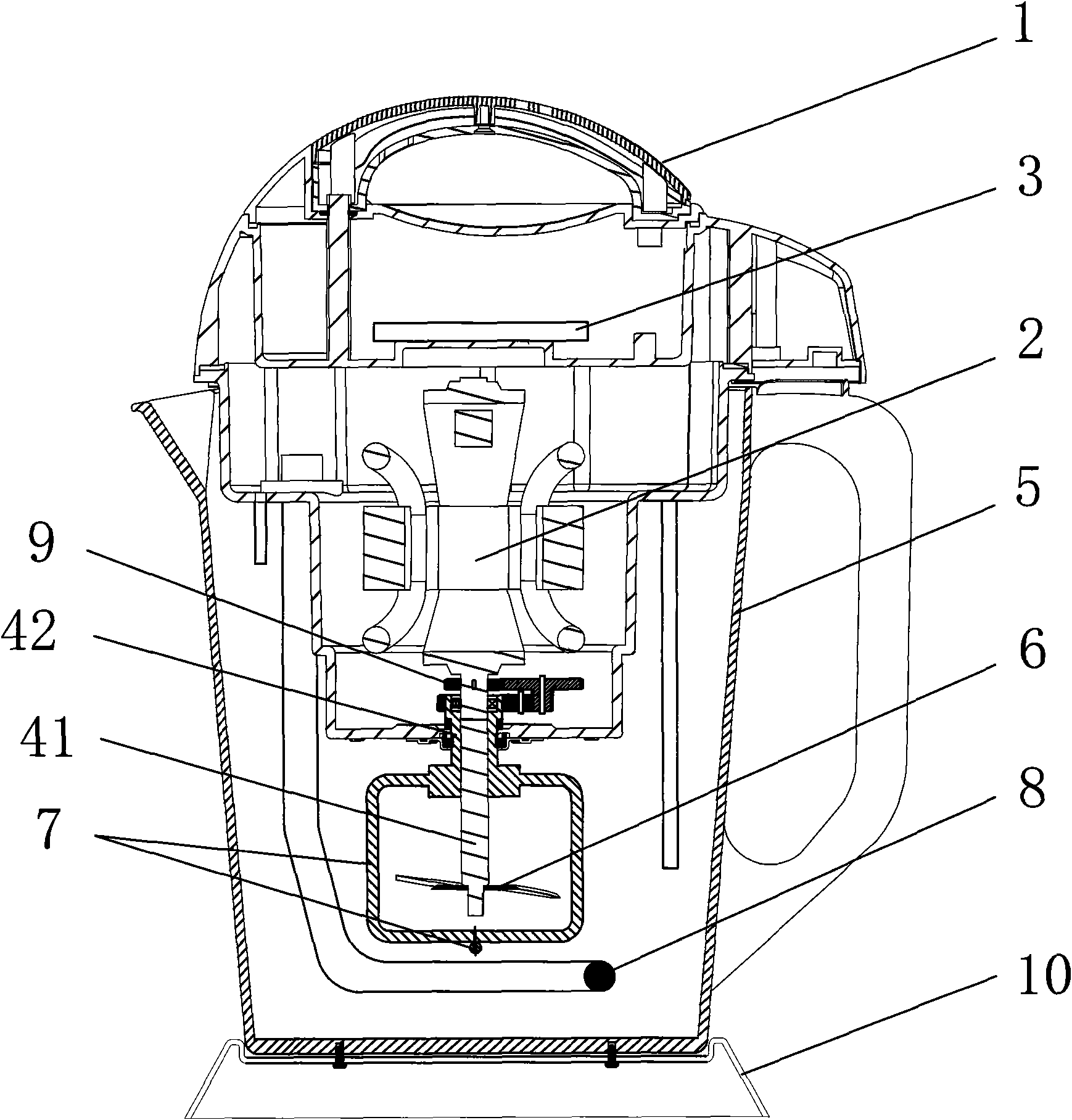

[0022] like figure 1 As shown, the present invention includes a base 10, a machine head 1, a motor 2 installed in the machine head 1, a control device 3, a cup body 5 and a heating device 8, and an inner shaft 41 and an outer shaft 42 extend from the bottom of the machine head 1 to Inside the cup body 5 , one end of the inner shaft 41 is connected with the crushing device 6 , and one end of the outer shaft 42 is connected with the stirring frame 7 .

[0023] In this embodiment, the inner shaft 41 and the outer shaft 42 are connected to the output shaft of the motor 2 through the transmission device 9, and the transmission device 9 is a gear transmission mechanism, and the transmission of the transmission device 9 makes the inner shaft 41 and the outer shaft 42 rotate The direction of rotation of the two is opposite during the time, and the control device 3 is installed in the head 1, and the heating device 8 is a heating tube, which is installed under the head 1 and extends do...

Embodiment 2

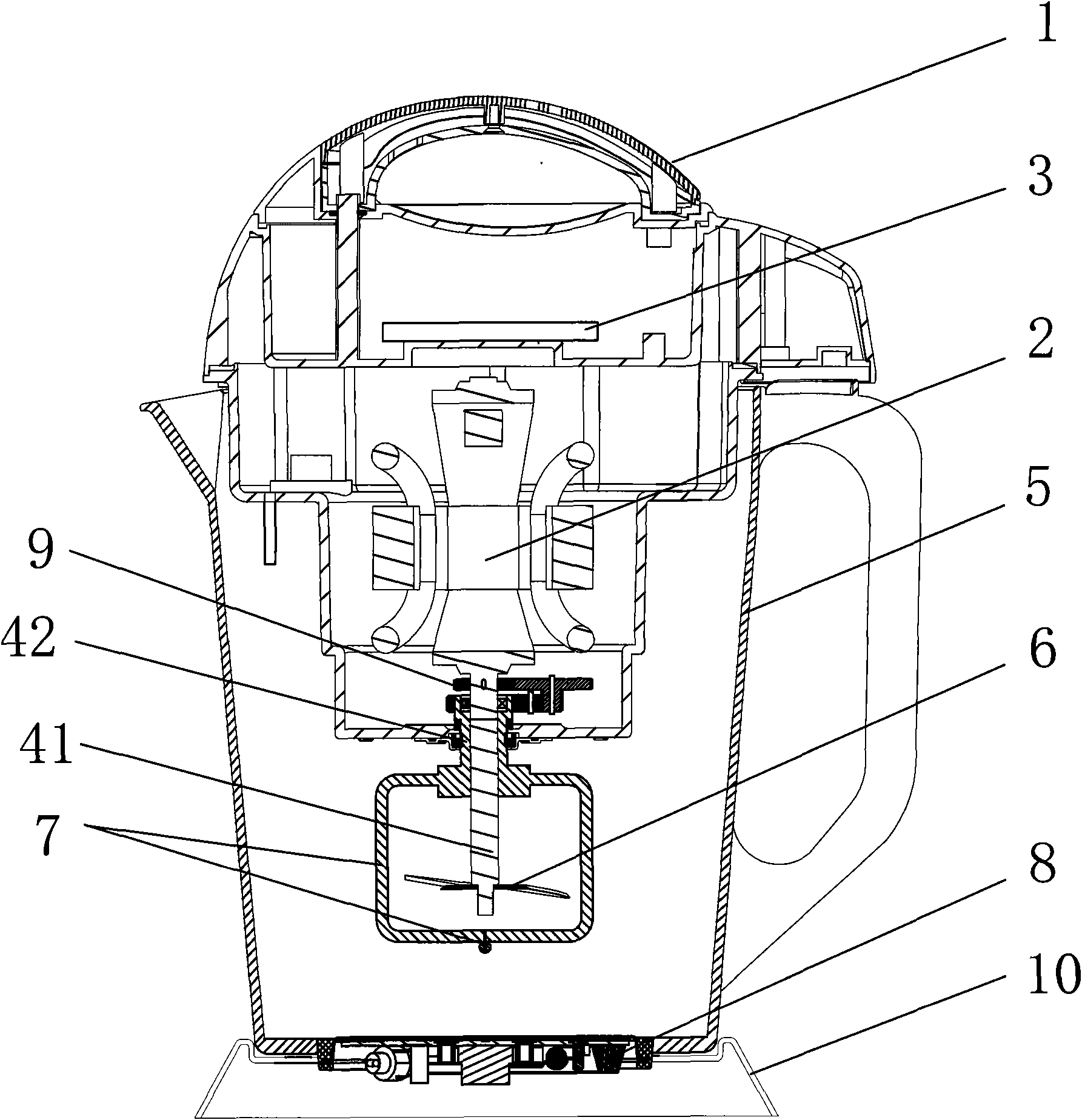

[0026] like figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the heating device 7 in this embodiment is a heating plate installed in the base 8 . Other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com