Intelligent vegetable harvester

A harvester and vegetable technology, applied in harvesters, balers, agricultural machinery and implements, etc., can solve the problems of high labor intensity, low operation efficiency, personal safety threats, etc., and achieve high baling efficiency and high harvesting efficiency. , The effect of conveying stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

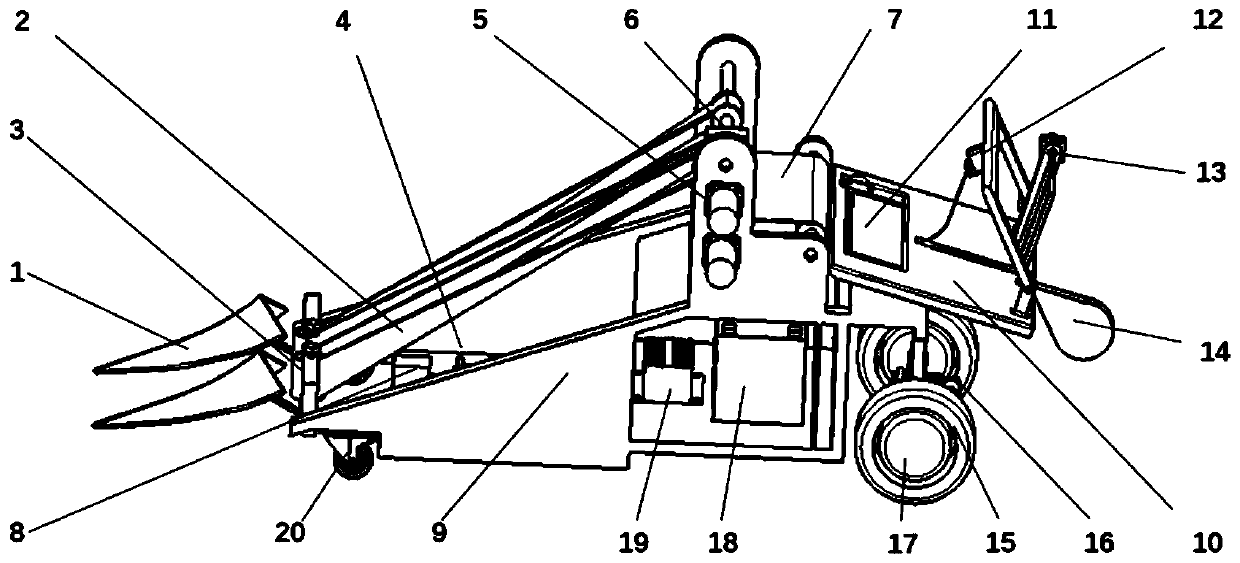

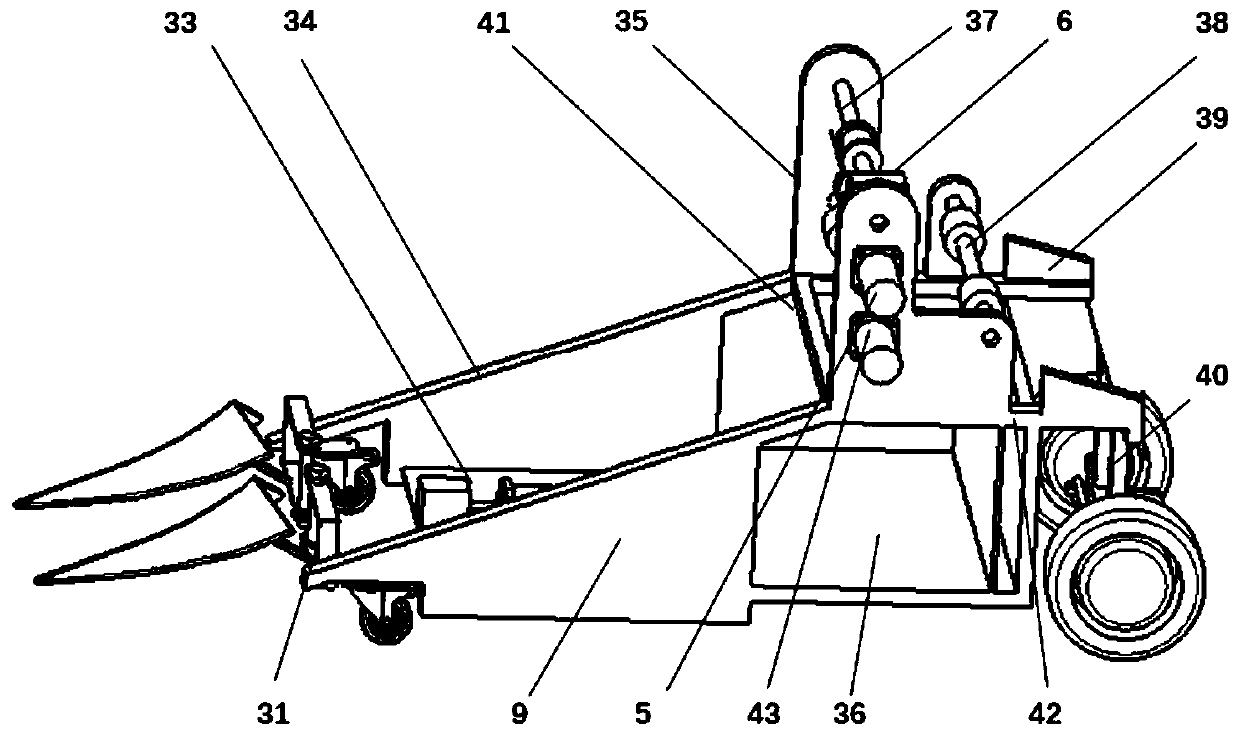

[0077] The following is attached Figure 1~6 The present invention is described in further detail.

[0078] An intelligent vegetable harvester, comprising a driving unit, a frame unit, a harvesting unit, a conveying unit, a bundling unit and an electric control unit, wherein:

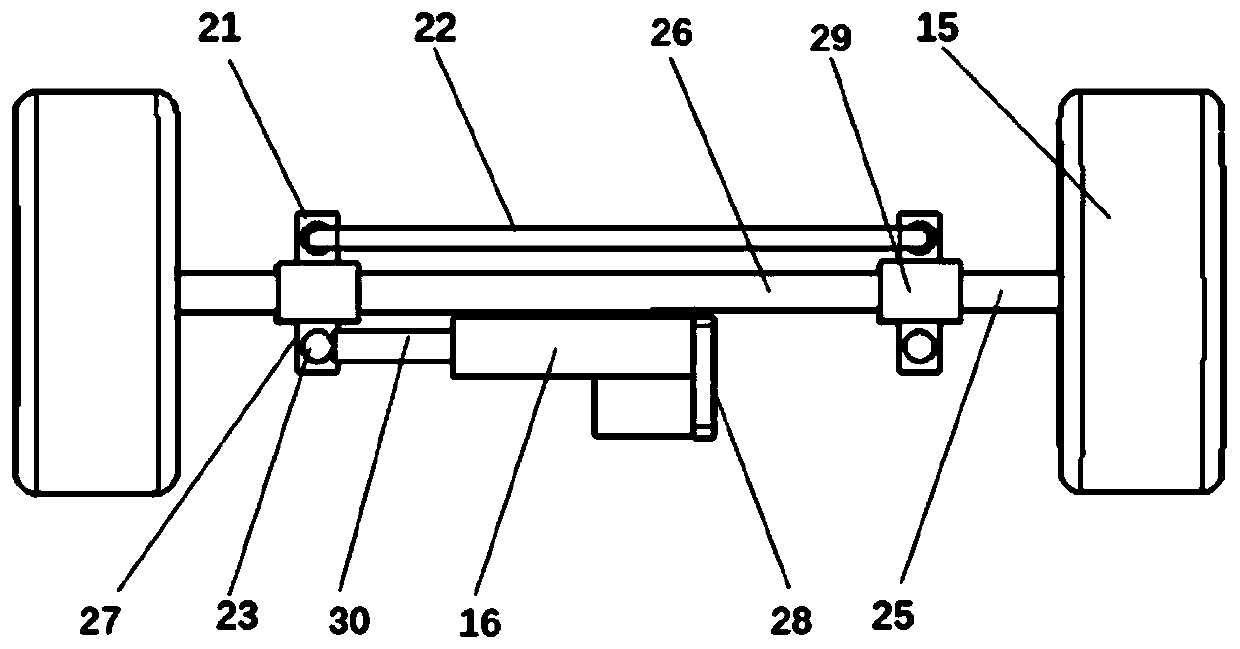

[0079] The drive unit includes hub motor 17, tire 15, axle shaft 25, push rod motor 16, steering knuckle arm 27, trapezoidal arm 21, steering tie rod 22, ball stud 23, intermediate shaft 26, push rod motor connecting plate 28. Push rod 30, C-type universal joint head 29;

[0080] The hub motor 17 is embedded in the inner side of the tire 15, the hub motor 17 is provided with a hub motor output shaft, the hub motor output shaft is connected with the tire 15, and the rotation of the hub motor output shaft drives the advancement and retreat of the tire 15; the push rod One end of the motor 16 is fixed on the intermediate shaft 26 through the push rod motor connecting plate 28, and the other end of the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com