Harvesters for vegetable harvesting

A harvester, vegetable technology, applied in the direction of harvester, application, agricultural machinery and implements, etc., can solve the problems of slow speed, high labor intensity, low work efficiency, etc., and achieve the effect of high efficiency, good harvesting effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

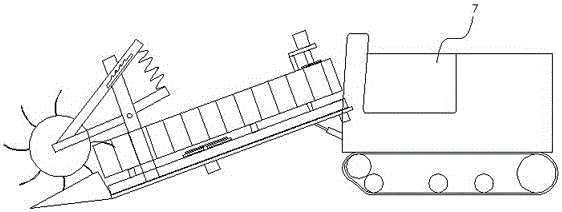

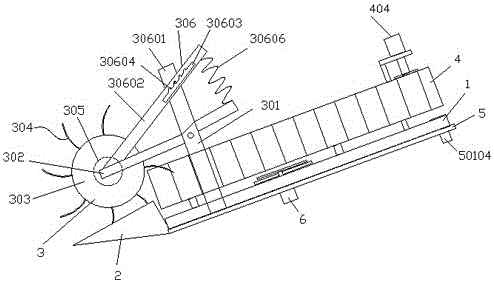

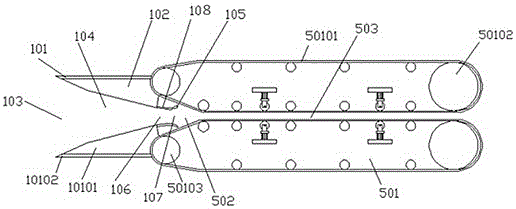

[0025] Examples, see attached figure 1 , 2 , 3, 4, 5, 6; a harvester for vegetable harvesting, including a harvester body 7, a threshing device arranged on the harvester body, a separation and screening device, a transmission device and a driving device arranged on the harvester body The above-mentioned structure is a well-known structure in the art, and will not be described in detail here; it also includes a support frame 1 connected to the harvester body, the support frame 1 is connected to the harvester body through a hydraulic cylinder, and is controlled by the lifting of the hydraulic piston The height of the support frame 1 is to adapt to different fields. The support frame 1 is a steel frame structure. A harvesting part 2 for harvesting vegetables in the field is provided at the front end of the support frame 1. The harvesti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com