Cotton stalk cutting bundling machine

A baler, cotton stalk technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

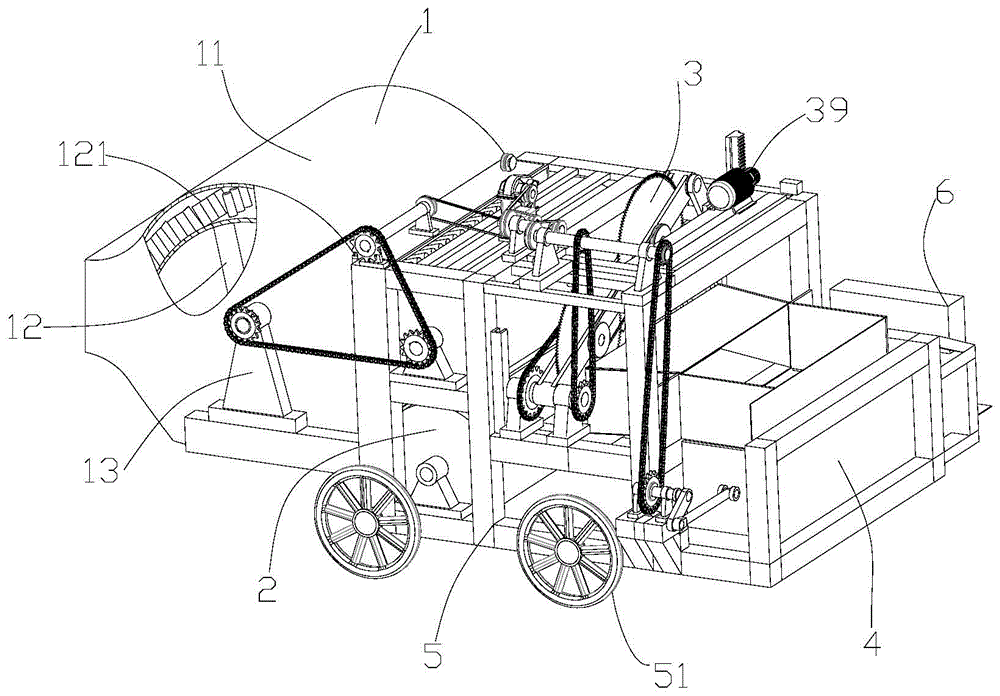

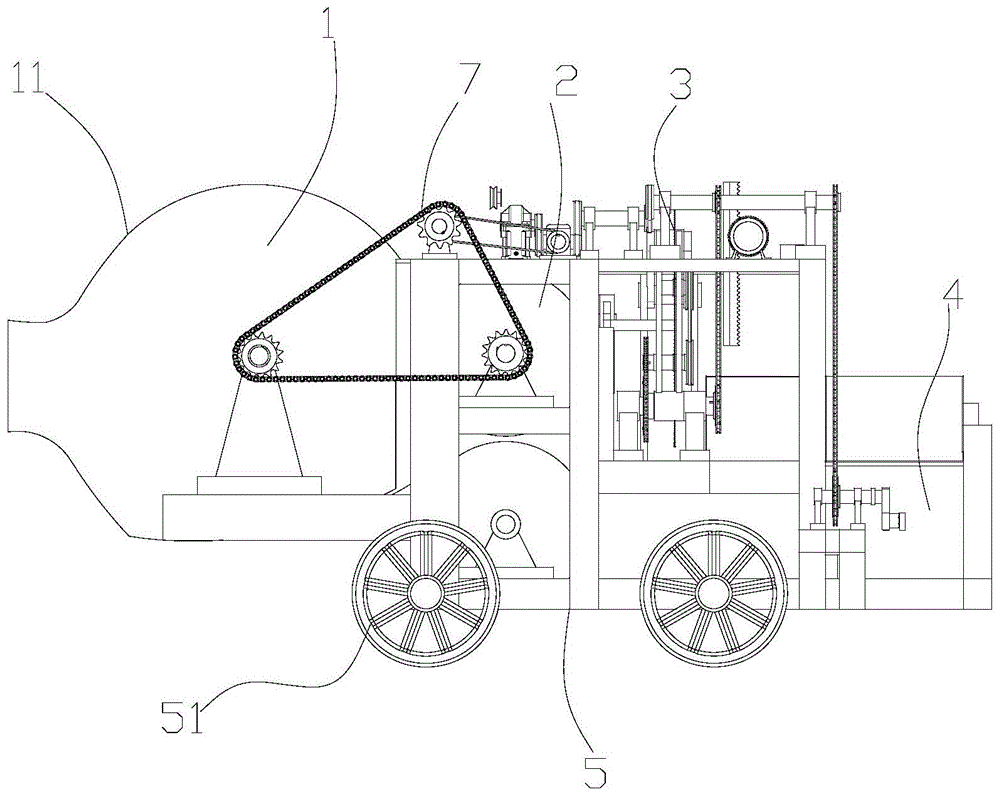

[0045] see figure 1 , a feed system 1 , a traction system 2 , a cutting system 3 and a compression and bundling system 4 are sequentially arranged on a walkable frame 5 .

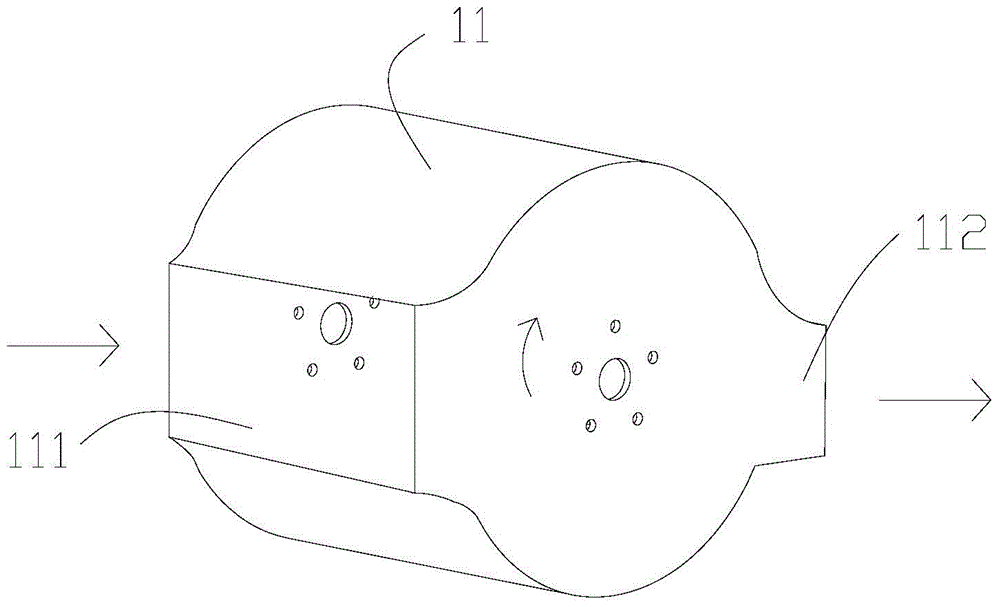

[0046] see in conjunction Figure 1-3, the feeding system 1 includes a feed hopper 11 and a rake-toothed roller 12, the left and right ends of the rake-toothed roller 12 are set in the feeding hopper 11 through a bearing seat 13, and the front and rear of the raked-toothed roller 12 correspond to the feeding hopper 11 respectively There are several rows of rake teeth 121 on the rotating rake tooth drum 12, and the cotton stalks are sent back to the discharge port by hooking the branches of the cotton stalks fed in from the feed hopper. .

[0047] see in conjunction figure 1 , figure 2 with Figure 4 , the traction system 2 is located at the rear of the feeding system, including two traction compression rollers 21 with upper and lower pairs of rollers, and the middle traction channel 22 of the two tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com