Crop reaping and binding machine

A technology of a baler and a baling mechanism, which is applied in the direction of balers, harvesters, agricultural machinery and implements, etc., can solve the problems of difficulty in grasping the best harvest timing, increased pod burst loss, and increased operating costs, etc. Achieve the effect of improving the economic benefits of crop production, alleviating the contradiction between the stubble and avoiding the loss of mildew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

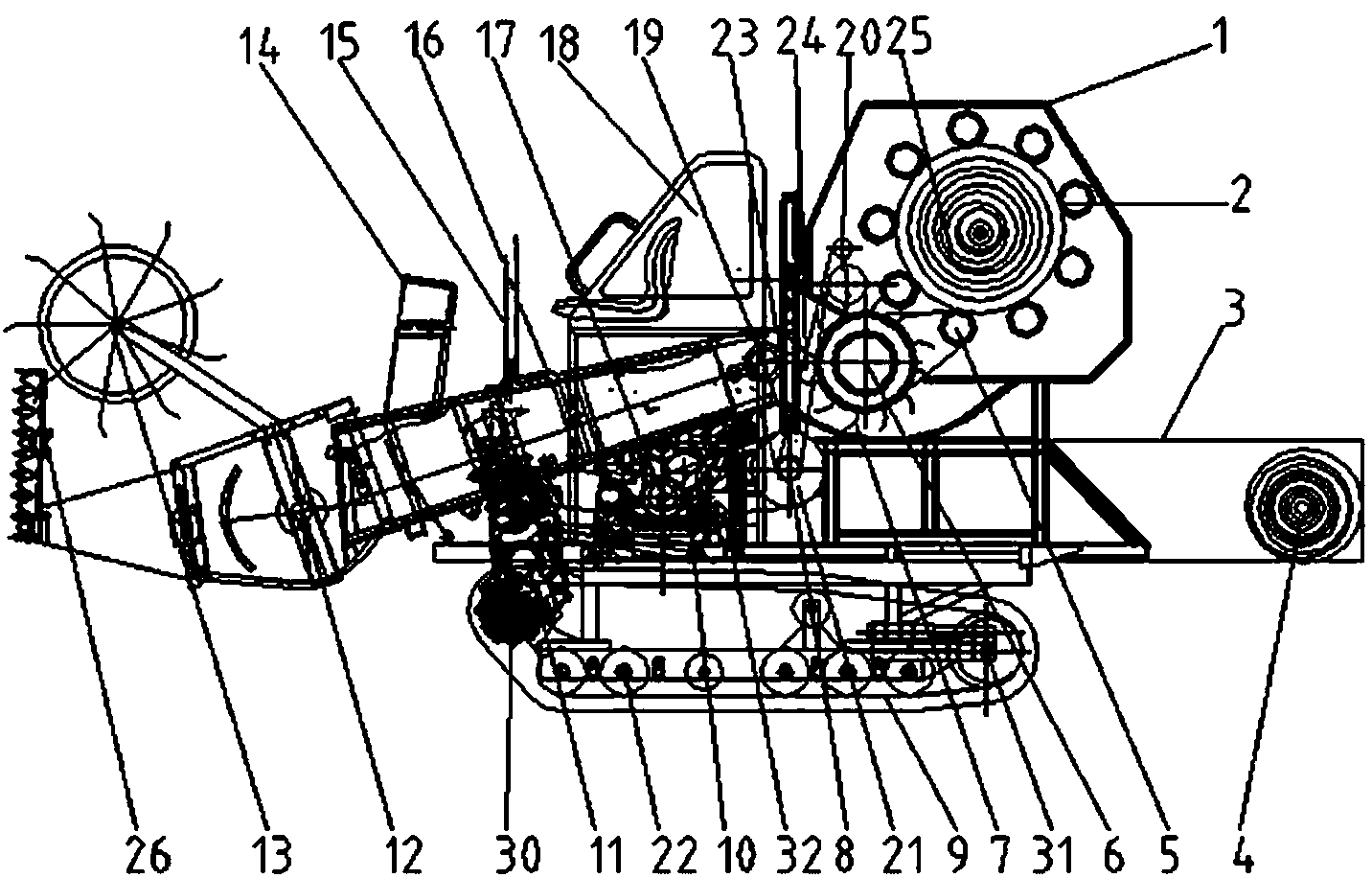

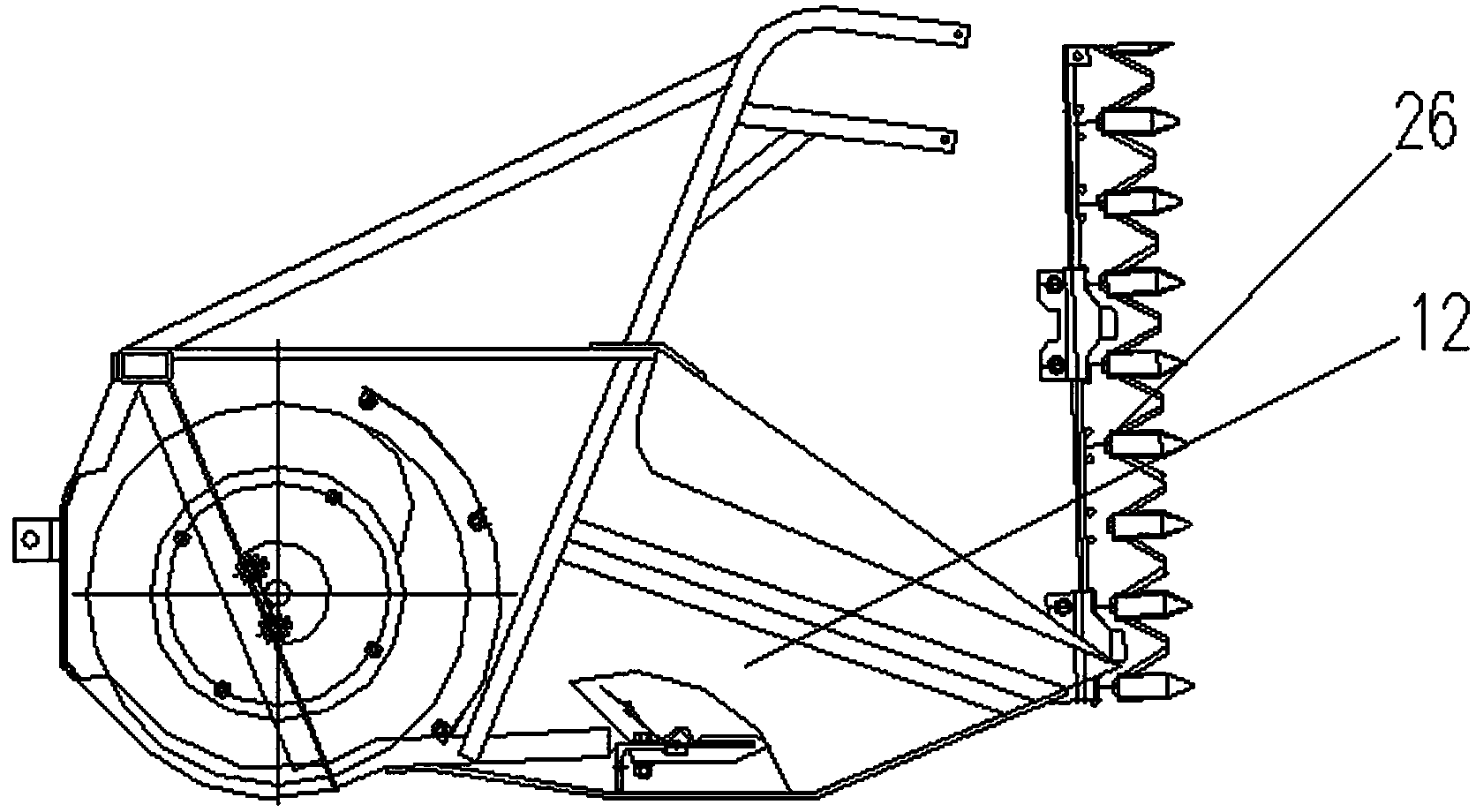

[0022] Such as Figure 1 to Figure 5 As shown, the crawler-type harvesting and bundling machine of the present embodiment is mainly composed of a header 12, a conveying trough, a feeding device, a bundling mechanism 1 and a power walking system and the like.

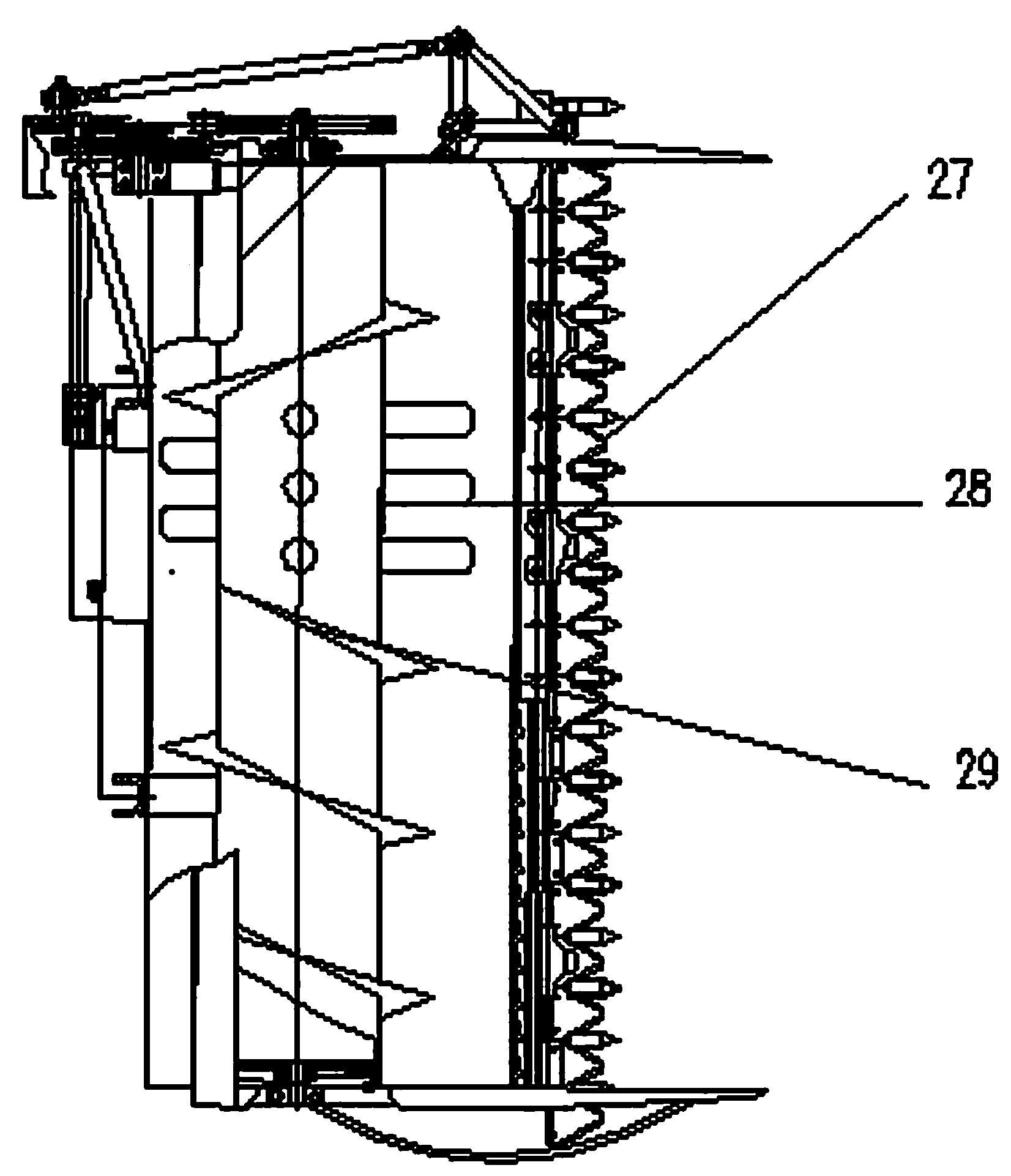

[0023] In this embodiment, the header 12 is mainly composed of a side reciprocating cutter 26, a lateral reciprocating cutter 27, a reel 13, a spiral auger 29 and telescopic teeth 28, and the crops are cut by the side reciprocating cutter 26 Cutting and separating are used to reduce the entanglement and resistance of the crops to the moving equipment. The horizontal reciprocating cutter 27 cuts down the crops, and the reel 13 shifts the crops to the auger 29, and the auger 29 transports the crops Dial to the delivery groove through telescopic grilling teeth 28 to the delivery slot.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com