Straw baler matched with wheel type harvester

A technology for harvesters and balers, which is applied in the field of straw balers for wheel harvesters, can solve the problems of poor connection reliability of drum wheels, easy sagging of drive sprockets, damage to reducers and balers, etc. Reliable connection, small vibration, and reduced failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

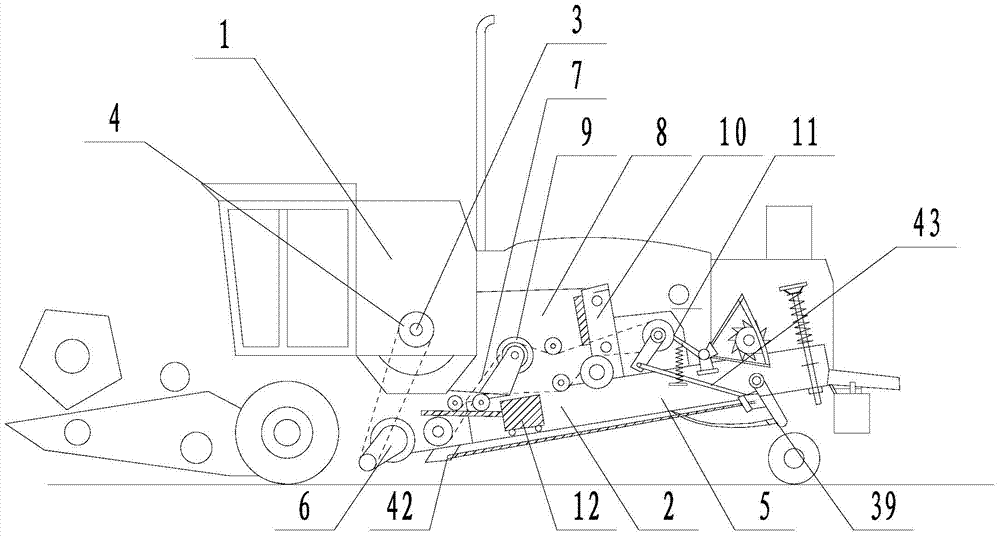

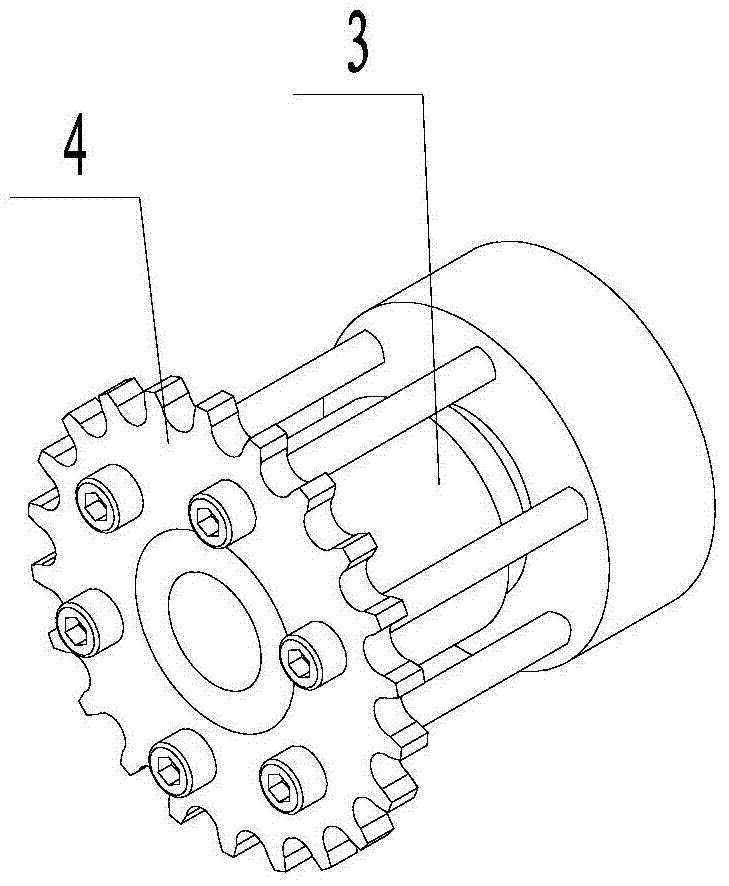

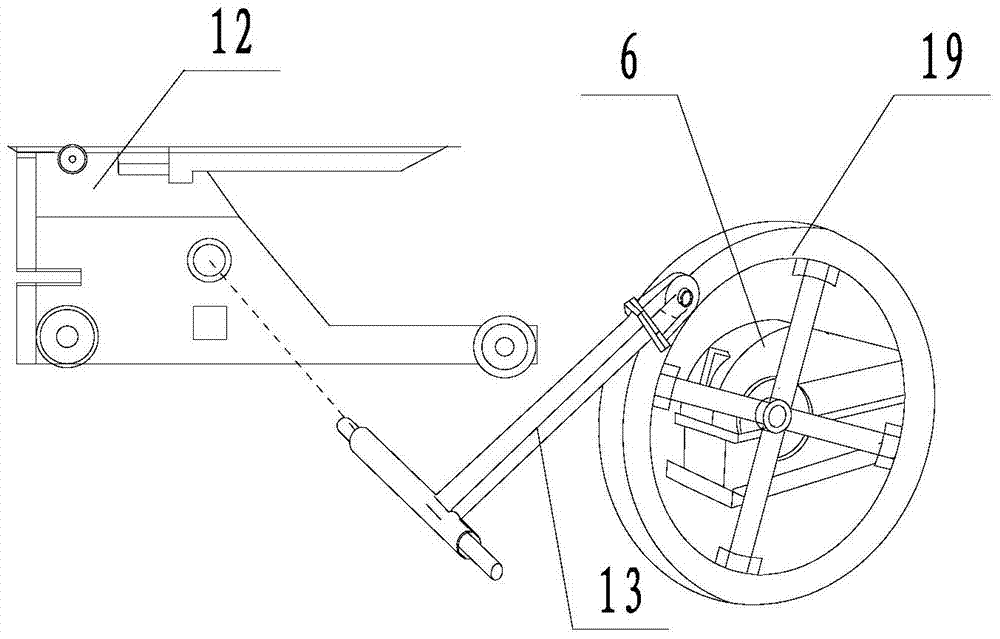

[0035] Embodiment: a straw baler supporting a wheeled harvester (see attached Figures 1 to 16 ), including a harvester 1 and a baler 2 installed on the harvester. The harvester is provided with a drum shaft 3, which is connected to a drive sprocket 4. The front end of the drum shaft is a stepped shaft-shaped structure, and the drive sprocket is sleeved on the drum At the small diameter position of the front end on the shaft, six fastening screws are uniformly connected to the end face of the driving sprocket, and the fastening screws are connected to the end face of the large diameter part of the front end of the drum shaft. The baler includes a baling box 5, a reducer 6, a transmission mechanism 7, a grass delivery box 8, a grass puller 9, a longitudinal grass presser 10, and a knotter 11. There is a material inlet at the upper end of the box near the front, a material outlet at the rear end of the bundling box, a piston 12 is arranged inside the bundling box, the front end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com