Dual cutting bench mechanism for harvester

A harvester and header technology, which is applied to harvesters, balers, agricultural machinery and implements, etc., can solve the problems of large grain loss and affect the threshing effect, so as to avoid grain loss, rational structure design, and prevent grain loss. The effect of mixing grains into straw

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

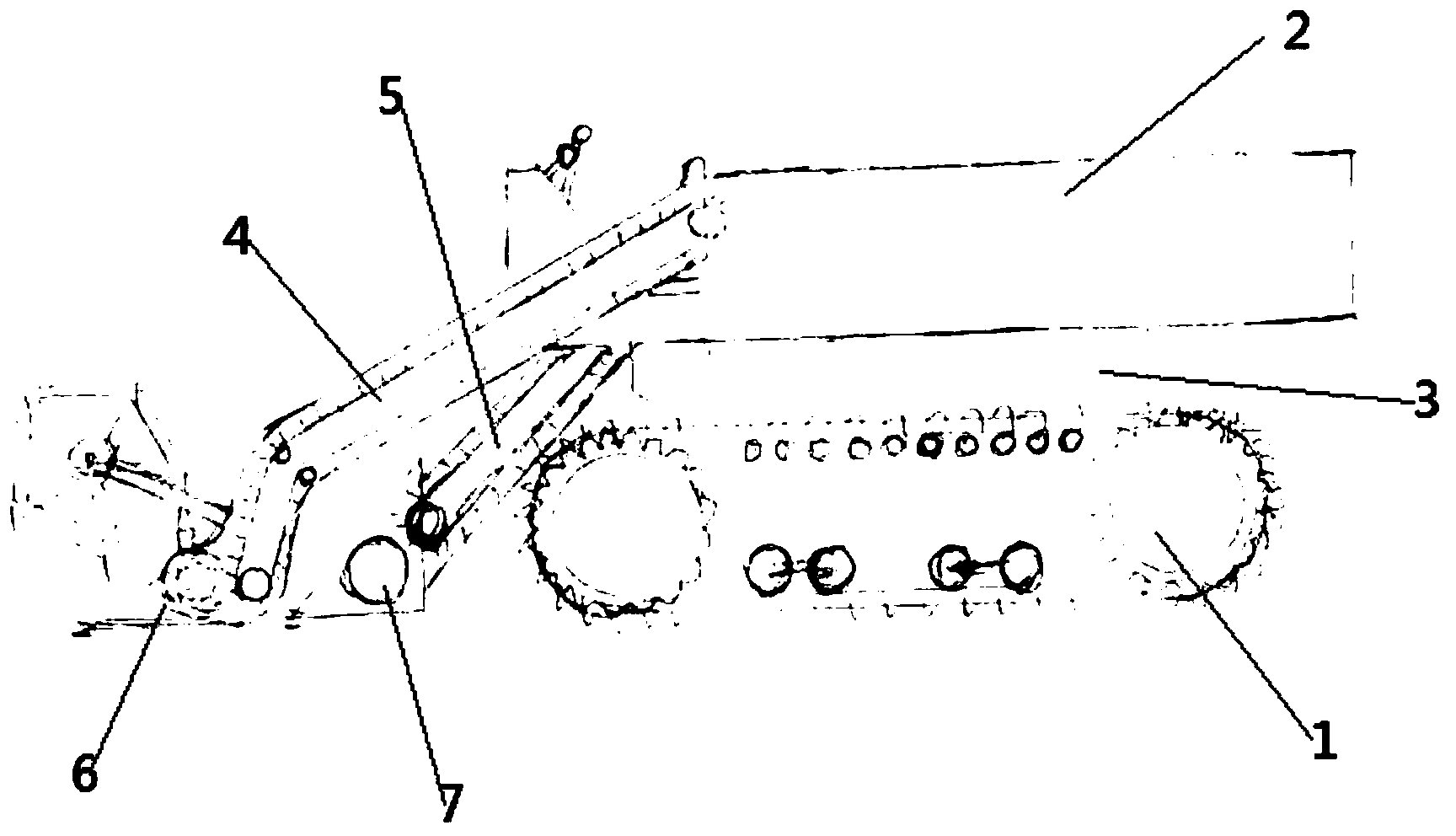

[0011] A double header mechanism for a harvester, including a frame 1 of the harvester, on which a threshing mechanism 2 and a straw bundling mechanism 3 are installed, including front and rear conveying channels 4, 5, The front and rear conveying passages 4 and 5 are respectively equipped with transmission mechanisms, and the output ports of the front and rear conveying passages 4 and 5 respectively lead to the threshing and screening mechanism 2 and the straw bundling mechanism 3; the input ports of the front conveying passage 4 The crop head harvesting mechanism 6 is installed at the position, and the crop straw harvesting mechanism 7 is installed at the input port of the rear conveying channel 5; the height of the cutter in the crop head harvesting mechanism 6 matches the height of the crop head, and the crop straw harvesting mechanism 7. The cutting knife is close to the ground.

[0012] The front conveying channel 4 is located above the rear conveying channel 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com